Welding related

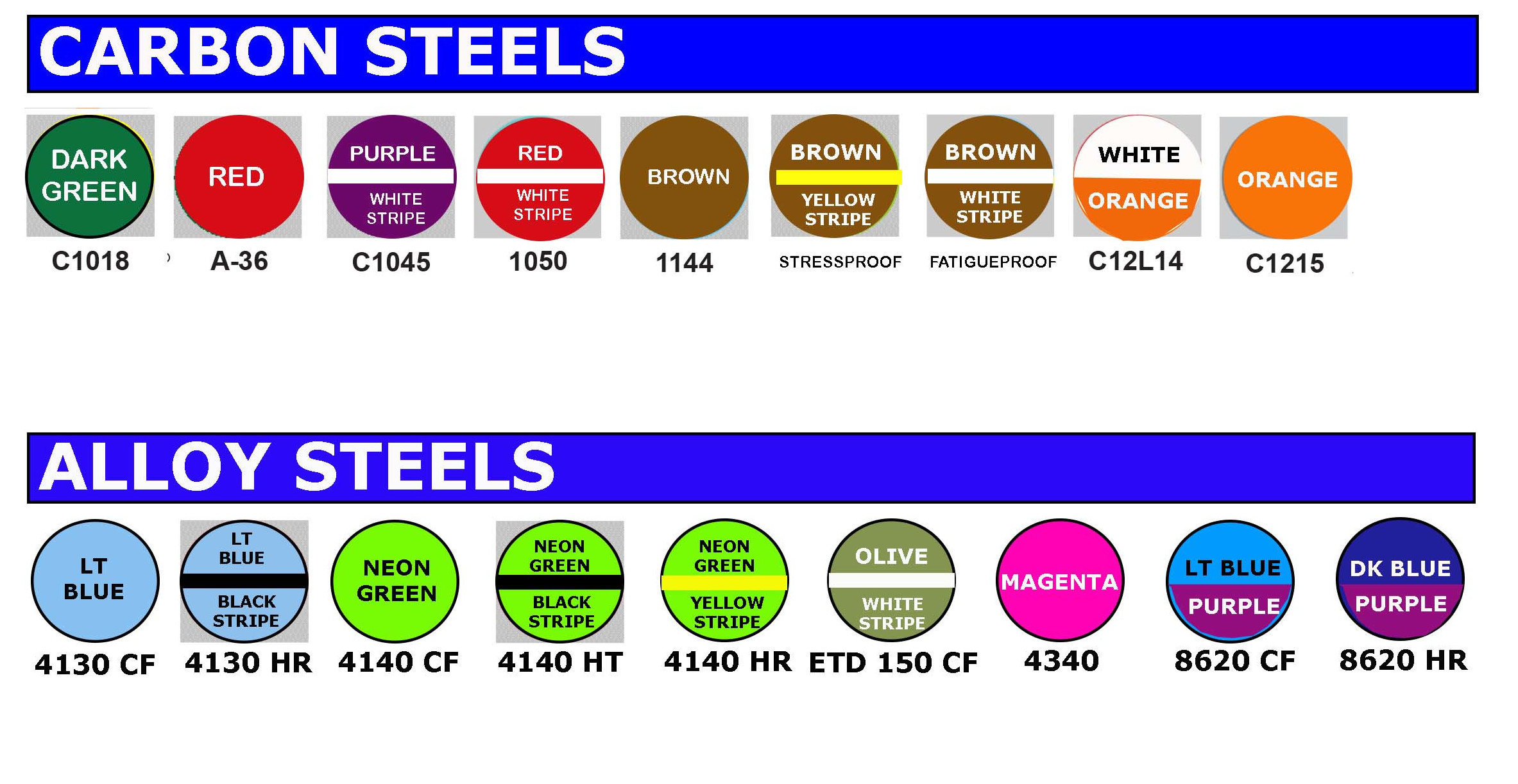

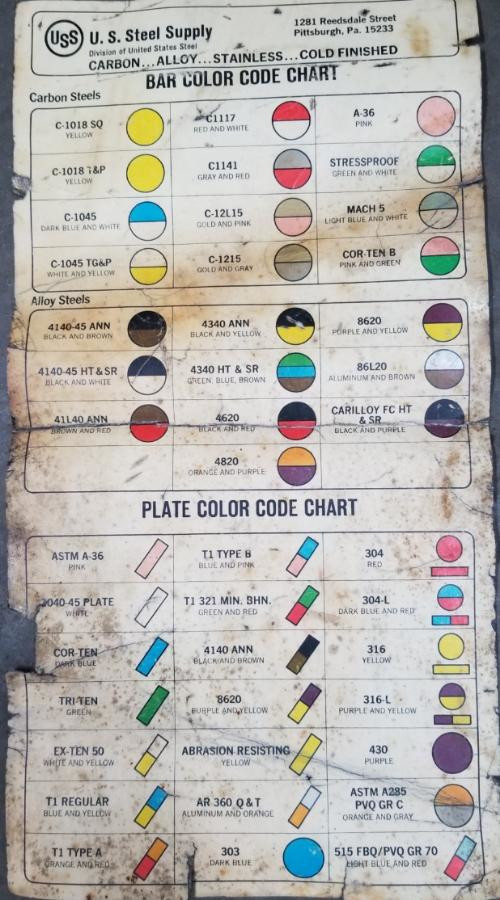

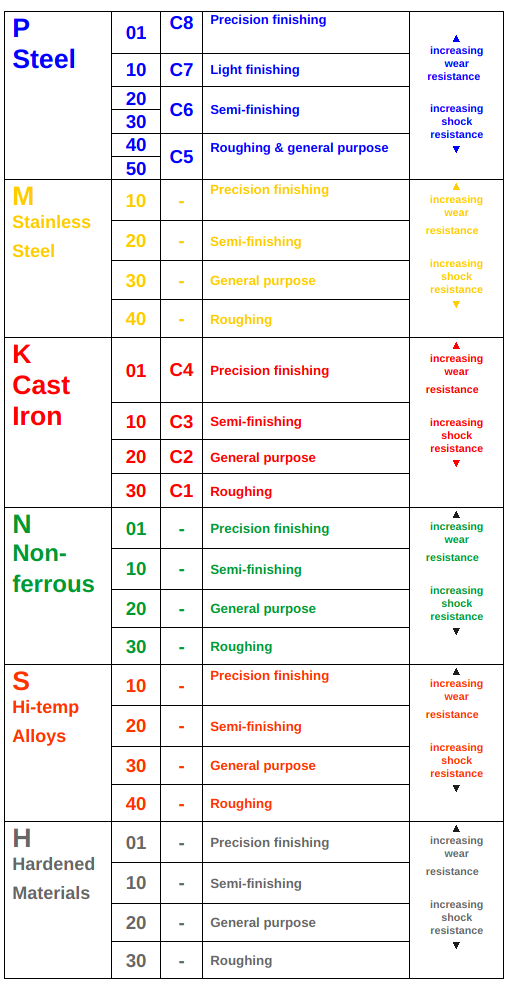

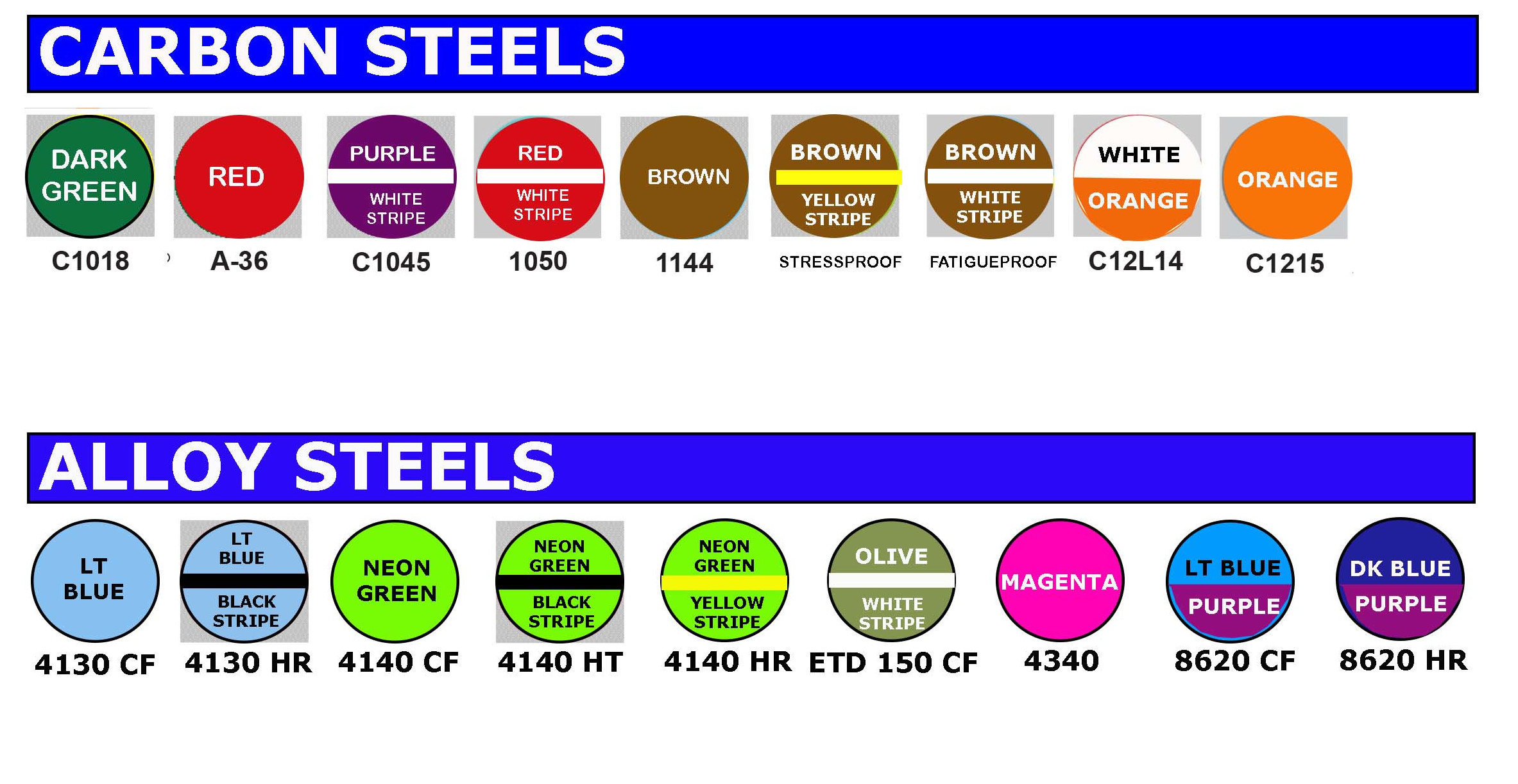

Detect, identify

metal type - see metals

Filler metal

ER309L - good maintenance filler - works well with combination

metals - like carbon steel to stainless. Best bet for mystery metals

TIG electrode

notes

| Tungsten Diameter |

tungsten area |

Gas Cup (Inside Dia.) |

Typical Current Range (Amps) |

|

Direct Current, DC |

Alternating Current

AC

|

| DCEN |

70% Penetration |

(50/50) Balanced Wave AC |

|

Ceriated

Thoriated

Lanthanated

|

Zirconiated

|

Ceriated

Thoriated

Lanthanated

|

Zirconiated

|

Ceriated

Thoriated

Lanthanated

|

| .040 |

Tables

63 |

#5 (3/8 in) |

15–80 |

20–60 |

15–80 |

10–30 |

20–60 |

| .062 (1/16 in) |

97

|

#5 (3/8 in) |

70–150 |

50–100 |

70–150 |

30–80 |

60–120 |

| .093 (3/32 in) |

146

|

#8 (1/2 in) |

150–250 |

100–160 |

140–235 |

60–130 |

100–180 |

| .125 (1/8 in) |

196

|

#8 (1/2 in) |

250–400 |

150–200 |

225–325 |

100–180 |

160–250 |

|

DCEN = Direct Current Electrode Negative (Straight

Polarity).

all values are based on the use of argon as a shielding gas.

other current may be employed depending gas, type equipment,

and application.

|

Lanthanated is probably the best all around type.

Color codes

Type of Tungsten

|

Color code

|

Description

|

Pure

|

Green

|

Provides good arc stability for AC welding.

Reasonably good resistance to contamination. Lowest current

carrying capacity.

Least expensive. Maintains a balled end.

|

Ceriated

CeO2

1.8% to 2.2%

|

Gray

|

Similar performance to thoriated tungsten.

Easy arc starting, good arc stability, long life. Possible

replacement for thoriated.

|

Thoriated

ThO2

1.7% to 2.2%

|

Red

Yellow

|

Easier arc starting. Higher current capacity.

Greater arc stability. High resistance to weld pool

contamination.

Difficult to maintain balled end on AC.

|

Lanthanated

La2O3

1.3% to 1.7%

|

Gold

Black

Blue

Yellow

|

Similar performance to thoriated tungsten.

Easy arc starting, good arc stability, long life, high

current capacity.

Possible replacement for thoriated.

|

Zirconiated

ZrO2

0.15% to 0.40%

|

Brown

|

Excellent for AC welding due to favorable

retention of balled end, high resistance to contamination,

and

good arc starting. Preferred when tungsten contamination of

weld is intolerable.

|

Tungsten Pure Green

Tig on cast iron - use Nickle 99 - actually a type of brazing.

Tip stick out rule of thumb - should be about the same as the cup

opening.

Filler for Au casting - 4047

Clamping and weld

distortion

Despite what people say - it is best to only clamp until the weld

tacks are in place. This is the same reason restraining the part (by

being fast so the rest of the metal restrains - or clamping)

increases the bend amount in flame straightening.

Argon Gas flow

Good starting point - set the LPM to the cup size.

Tool steel like rod

-

weld mold 958

D2 tig filler metal

Stellite 6/12 tig filler - very hard https://www.stellite.com/us/en/products/hardfacing-alloys/welding-rod.html

c83 rod

Spot Welding

Electrode tips copper tungsten or copper chrome

Spot welding aluminum

Put the aluminum sheets in between sacrificial stainless sheets.

Silver solder

Stay bright - low temp

High temp use Safety silv 56

Stay-Silv by Harris (Robrenz uses) high temp brazing flux(water

based) turns clear at temp

Heat bigger part first

Harris Safety-Silv 45 brazing temperature is1370⁰ to 1550⁰ F.

Safety-Silv 56 is 1200⁰ to 1400⁰ F.

Safety Silv white flux active range 1000⁰ to 1600⁰ F. Safety Silv

black flux active range 1050⁰ to 1700⁰ F. Also the black flux

has a boron content that extends its working time. Flux activity is

time limited at brazing temperature.

The liquid flux oxidizes in air over time forming a tough film that

inhibits joint wetting. For that reason, plan your operation - do

not dally.

A final point is joint cleanliness. Clean the joint thoroughly, then

scrub the joint surfaces with Comet cleanser, a stiff brush, and

water followed by a hot water rinse. Do not follow with a solvent

clean (any solvent) Conventional wisdom decrees a final

acetone wash. Acetone is a commercial product containing impurities,

reaction fractions, wax, and tramp particulates. These pyrolyze and

inhibit flux activity and joint wetting.

Comet cleanser as your last step makes a huge difference

ZYP Coatings makes a Boron Nitride Aerosol Lubricoat that can be

used as a solder resist. Cheaper to get Boron Nitride as 'white

graphite'.. - found powder - mix with bit of solvent (acetone

or ethanol) Spread on as a resist.

mystery metal -

pot - aluminum?

AC - 200A Pulse - 120/s PK95 Bk70 240Hz - fresh air..

TIG Brazing -

silicone bronze

Don't puddle base metal -Stay over bronze - just hot enough

to not ball up. AC or DC - lay-wire- don't dab - pulse

DC is probably best -- 100A good place to start.. clean everything

- even rod .. Pulsing 1-2/sec 33%-background 33% at

peak lets you lay-wire - dabbing makes oxides. Half

strength of steel - but less distortion.

Tig Brazing Cast

Iron

For cast iron - preheat to 425C

Si Bronze AWS A 5.27 RBCuZn-C melts at 860-890C Tensile Strength 460

MPa 60-68kpsu

Nickel 99 NICKEL 99 AWS/SFA 5.15 Eni-Cl melts at 1453C

Yield - 36-50ksi

TIG settings

starting recipes

Aluminum

Frequency - 90-120 - the higher the frequency the tighter the

arc-cone - and less heat/penetration

Balance -- about 70 Lower cleans more

Pulse settings (helps with melt through) 1.2-2hz (Pulses-per-Second)

for adding filler synchronized. On time 50% Back ground 25-40%

Metal Files

Cut numbers are not the same for different types of files! They

really should specify the Pitch - but don't! Need a Graticule

or Reticle to measure it.

Cut rating of files:

Cut number

|

Pitch um

Needle

and Escapement

|

Pitch um

Swiss pattern

4"-8"

|

00

|

498

|

620

|

0

|

397 |

498

|

1

|

322

|

397

|

2

|

261

|

322

|

4

|

179

|

217

|

5

|

147

|

|

6

|

119

|

147

|

8

|

86

|

|

Adhesives

epoxy

Frisket film makes for a good resist.

Loctite

Red loctite 263

mounting wax

https://www.amazon.de/WEKEM-Sekundenkleber-hochviskos-dickfl%C3%BCssig-schwarz/dp/B01AWFQBV

WEKEM WK-2400 Good for gluing shim stock for stops

MEK can be used to thin epoxy..

Loctite 1712314 repositional spray adhesive

Hylomar

- gasket material - also keeps things from vibrating lose that get

taken apart repeatably - not as strong as loctite blue. Does

not significantly change dry fit up dimentions. Requires true

surfaces.

Loctite colors.

Purple Low Strength Threadlockers.

Blue (243): Medium Strength Threadlockers.

Green (294): Penetrating Threadlockers. - wicks into cracks - heat

to remove

Red - highest strength -heat to remove.

Black - toughened superglue - 438 for work holding.

styrene butadiene

(Goop) (oil resistant)

Can be smoothed/formed by thinning with Toluene

Chemicals

that have little or no effect on Goop II max

(percentages are given by weight unless otherwise noted.)

Acetic acid (5% and 10%)

Ammonium hydroxide (3.4%)

Ammonium nitrate (50%)

Antifreeze

Beer (3.2% alcohol by volume)

Boric acid (3.1%)

Distilled water

Hydraulic oil

Lactic acid (3.8%)

Milk (fresh, tested at 40 °F)

Motor oil (30w)

Nitric acid (10% and 20%)

Oxalic acid (3.1%)

Phosphoric acid (30% and 60% as P2O5)

Potassium hydroxide (3.4%)

Sodium carbonates (2.7%)

Sodium chloride (10%)

Sulfuric acid (3% and 10%)

Wine (20% alcohol by volume)

exhibits excellent resistance to water, dilute acids and dilute

bases. Thin films of AMAZING GOOP® II MAXTM were immersed in various

chemicals for two weeks and exhibited weight gains of less

than 2% and tensile strength loss of less than 10%. These

chemicals are listed on the left.

Blackmax 380

rubber toughened ethyl cyanoacrylate adhesive with increased

flexibility, peel strength, and enhanced resistance to shock for

temp stops - fixtures

3M-467 tape

adhesive only -- holds things. - replace adhesive on

stickers/plates. - Robrenz recommended.

Teflon tape

mc 76475A51 - lots of varieties - sticky one side - teflon the

other.

Epoxy

PC.7

- good filler and strong - slow set

BSI

Has 5min and the stronger slow set - clear-ish -

Loctite 1373425

Hysol 1C

Top quality epoxy Shore Hardness 65 Shore D, Shear Strength 1500

psi

epoxy tramming -

slide forming

https://www.diamant-polymer.de/en/products/moglice/

https://www.diamant-polymer.de/en/products/dwh/

Rulon 142 or Turcite

DIY moglice - DHW epoxy filled with more than 80% by weight

steel.

-p is paste like

--FL is pourable.

DWH-310-FL viscosity 12k-14K (low viscosity) Steel filled

DWH-310-P low viscosity - coating of parting lines - mounting

surfaces

DWH-311-FL viscosity 20-25k - still low.. aluminum

filled

DWH-314-FL viscosity 28K Mineral filled

Moglice 1000-FL - Has low friction additives

the regular moglice has graphite and molybdenum disulfide -

Recipe from patent - percent by weight:

- epoxy resin: 40-80 --- 60

- molybdenum disulphide: 15-30 22

- graphite: 10-15 12

- aluminum: 5-10 7

- copper: 5-10 7

- alumosilicate: 8-15 (glass )

- polyethylenepolyamine: 5-10. (ph control? likely in most

epoxies )

Poor mans recipe epoxy 70 moly 20 graphite 10 - needs test.

The putty moglice is scrapable - but soft - easy to go to far.

The DWH - fitting epoxy..

Adhesive removal

Plexiglass backing gets old and hard to remove - soak in pure

cleaning ammonia - scrape off the paper layer - let dry - cover with

methanol - wait a bit - scrape.

Bits - drills -

reamers - boring - milling cutters

For hard metal - high Rock

Carbide bur for phenolic SGStool.com 73011 FGR #9 Style A

Diamond burr for aluminum??

O-flutes for plastics https://www.onsrud.com/articles/O-Flutes-For-Mechanical-Plastics.asp

https://www.onsrud.com/Series/SolidCarbide1-2FluteDowncutPlastic.asp

For cutting Sheet

metal - routing

Use chamfered endmill and .1 - .2mm depth of cut, with high feed

rate.

Taps

Always get taps with PM in the part number - powdered metal - HSS

Extensions - best are RITMAR

Lisle LI70500 tap socket set - combine with a

ball spline assembly - ball spline bushings.

Abrasives,

Lapping, and grinding

Lapping Notes

The groves in a lapping plate make a difference. The edge

of what you are lapping will pile up abrasive and cut more - the

groves help prevent this. An iron lapping plate can be

covered with a polycarbonate film (stuck on with some

purple-power) - or use thick aluminum foil (can't find anymore?).

Lapping

details

Lapping Abrasives

PSA diamond film - use PSA only for roughing and be meticulous about

cleanliness, dust or hair will make it almost impossible to use.

With plain film back just spray the back with water and squeegee it

to the plate.

Eye - lap (mcmaster) copper tool for lapping ID to match pins

3M™ Microfinishing Film Roll

12" wide x 25 yard roll of 220 grit Silicon Carbide paper -

Abrasives South Inc. 1-800-255-8112 #18014 roughly $100.00

cerium oxide

At the finest level - lapping after scraping - don't use diamond or

sil-carbide - instead .03um alumina- it breaks down - removable with

kerosine (why not cerium oxide? )

You can see fringes on high spots. Alumina 9Mohs, Cerium oxide 7mohs

- optical rouge lower yet -- iron 4-5 steel knife 5.5 - file 6.5

Graded grits

https://www.hisglassworks.com

https://gotgrit.com/

http://firsthanddiscovery.com/

https://www.us-nano.com/inc/sdetail/21645

https://www.kemet.co.uk

Sand paper for

metal

Most of the skilled people use 3M wet/dry - wet with WD40. - 240 -

320 - 400 followed with Scotch bright is common..

Deburring

Cratex Brightboy stick deburr https://www.cratex.com

Coarse = 125um 1.06um-Ra

Medium = 85um 0.48um-Ra

Fine = 65um 0.30um-Ra

xtra-fine = 25um 0.1um-Ra

Scotch-Brite EXL Unitized Wheel, Silicon Carbide,Fine Grit

Cut off wheel -

use for tool grinding

3M™ Cubitron™ II Cut-Off Wheels for gross material removal (of High

Speed Steel) 1mm thickness 65512

PGS (Precision

Ground Stones)

Clean surface first with solvent - remove oils.

Start off dry - oil on the stone removes the sensitive feel.

Prepare the work by removing large burrs with a file or regular

stone.

Clean and rub the stones first - we want a floating flat feel.

Slide stone gently onto work - you can feel tiny burrs sticking up -

think of these stones as a kind of test tool.

If you feel a big burr - use file or regular stone again.

Feeling something rolling? Stop at once, and clean then rub stones

again.

If things feel smooth try pushing a bit harder - follow grind

direction.

To go a little further - use a bit of acetone or alcohol - don't use

oil. Anhydrous isopropanol likely best. Lubrication removes the

sensitive feel and sound of the stones.

Stones can be cleaned via ultrasonic tank - water based cleaner -

Alconox - allow stones to completely dry before using.

When finished - the bare steel can rust - protect it with your

favorite schmoo.

PGS were invented by Harold E. G. Areneson (RIP) of Professional

Instruments Company - also invented high precision air bearings that

had a central sleeve that apparently compensated for load.

Grinding wheels

Surface grinders normally run at 3-4K-RPM slowing has the

effect of a softer wheel

Typical starting point 46 H or I

10 structure

Percent Concentration Diamond/CBN - concentration is the ratio

between the diamond/CBN grains' weight and the volume of the

abrasive layer. Standard concentration = 100 equals 4.4 carats per

cubic centimeter. Thus concentration can be over 100.. 200

would be 8.8 carats/cm3

Harder J-K 60-80 are for 'form' grinding

Depth of cut 5-15mills(125-400um) roughing 2.5um fine finishing

9A60JV tool post grinding wheel

These guys might have better wheels.. https://cuttermasters.com/

Continental diamond tool https://www.cdtusa.net/ used by solid

rock..

radiac

Lapping machine

Alumina disk - out of chemical laboratory - used with diamond - 1um

as a charged lap for mirror finish - Stephans disk is only 100mm

he gets 1000grit(about 15um) for his first polish - near

mirror.. M5 screw hods it together. Wheels from search

terms "faceting lap" "Lapidary - gem polish" etc.. Don't get the

cheapest.

Also he touched up an insert with 1um diamond paste..

U2 Deckel style

D-bit grinder

Shars 101-1008

Wheels are ⌀4" outer diameter ⌀1.25" bore.

Gaskets

Sealers

Hylomar is the deal for close fitting things - solvent is

acetone. Maximum surface roughness target 2um-Ra

Ball bearings

Class 1, 3, 5, 7, and 9. The Higher ABEC classes provide better

precision, efficiency, and greater speed capabilities.

Lubricants

Liquidmoly LM 48 - assembly grease (Stefan likes it) for

chucks etc.. https://products.liqui-moly.com - or blue moly? For

assembly - not moly -- High-performance tungsten disulfide paste for

heavy-

duty applications. It adheres even to apparently smooth surfaces.

Rubbed into bearings and slideways, it prevents running-in damage

and seizing marks when assembling components with tight pair-

ings. Contains a synergistically active solid lubricant system with

a zinc sulfide, graphite, fluorides and tungsten disulfide base.

Operating temperature range: -35 °C to +450 °C.

One can also just mix some molybdenum disulfide in to a bearing

grease - I like the idea of the first lube having a bit of moly in

it.

Never-seize (AKA Never-sneeze) - Blue moly has more of moly -

molybdenum disulfide 7-13% and pure nickel powder 7-13% NLGI = 0.5 -

not for high speed bearings. The grit is abrasive - but keeps bolts

from seizing. 'Black moly' has even more molybdenum disulfide

10-30%. Zinc Oxide 5-10%. Don't use as assembly grease on

bearings.

Vactrac A better way oil? Harig oil16211245 http://www.trutech.store/harigstore/product.php?productid=17810

Penetrating schmoo

Commercial mixes of penetrating stuff don't penetrate quickly. Kroil

and WD40 can work, but the winner by a factor of 10 is something you

mix yourself. 50/50 solution of acetone and automatic transmission

fluid. It's a mixture not a solution so you have to shake well

before use. Apply liberally and it should loosen within 24 hours.

(has anyone tested this?).

MMO (Marvel

Mystery Oil) Lots of exaggerated claims - contains:

Petroleum distillates (hydrotreated heavy naphthenic) also known as

mineral oil, 74%

Petroleum distillates (Stoddard solvent) also known as white spirit,

25%

Tricresyl phosphate, an antiwear and extreme pressure additive in

lubricants 0.1–1.0% (an antiwear and extreme pressure

additive)

Ortho-dichlorobenzene, a softening and removing agent for

carbon-based contamination on metal surfaces, 0.1–1.0%

(high-boiling solvent)

Para-dichlorobenzene, a precursor used in the production of

chemically and thermally resistant polymers, <0.1% (moth

ball - preservative?)

Cutting lube -

coolants - schmoo

Aluminum routing - pure A-IPA mist - tiny amount - easy clean up.

Kool-Mist will spoil and plug up sprayers and stink - add tiny

amount of some ORTHO-BENZYL-P-CHLOROPHENOL (Lysol concentrate - out

of UK in 2020)

Make a heavy metal jar for schmoo - JIC hydralic cap and

plug -20 (1.25")

coconut oil - 0.5% boric acid (50nm particle size)

anchor lube

Kleen flo

rapid tap

QualiChem Quick Tap Extreme-Duty what Edge precision is using for

tapping.

Aluminum tap majic (Abom likes.)

Mistic Metal Mover (Abom likes for cutting stainless)

Stephan uses Jokisch Alpha 93 cutting oil - comes in aerosol (I

like)

https://www.blaser.com

makes very clear stuff - need to find out what is in

synthetics. https://www.qualichem.com

jokisch alpha 93 cutting oil ( Stephan) https://www.jokisch-fluids.de/catalog/en/metalworking-oils/cutting-oils/

https://www.hoffmann-group.com/GB/en/houk/Chemical-technical-products/Lubricating-coolants-cutting-materials/Cutting-oils/High-performance-cutting-oil-chlorine-free-Alpha-93/p/084210

qualichem tapping fluid - used by Peter Stanton

Lens cleaner - first contact

Viscous grease https://www.nyelubricants.com/damping

prevention

johnsons wax - chain wax??

Break Free CLP

ferrocote 5856 - source for small quantities???

Grease

Mobil Grease 28 - spindle ball bearings and ballscrew - thrust ball

bearings - think of this as ball bearing grease

Assembly grease - Liebherr Compund CTK -- Liqui Moly (20216 LM 48

Assembly Paste)

LTS-1 low temp - good water resistance aluminum

AP(All Purpose) Grease is a lithium based multifunctional high

temperature, water resistant grease

MP(Multi Purpose) grease number 2 grease?? washproof?

EP Grease(Extreme Pressure) EP grease has in its components, solid

lubricants (graphite and/or molybdenum disulfide) to provide

protection under heavy loadings.

NLGI consistency number (sometimes called “NLGI grade” or "NLGI

number") expresses a measure of the relative hardness of a grease

LUBE SPECS

Tables

| LUBE CODE |

LUBE |

FS SPEC |

| 4 |

DRY |

NA |

| 12 |

WINSOR LUBE L-245X |

FS171A |

| 23 |

ANDOK C |

FS118 |

| 37 |

DOW CORNING 44 |

FS137A |

| 44 |

ANDOK 260 |

FS167E |

| 49 |

ANDOK B |

FS104A |

| 67 |

RHEOTEMP 500 |

FS208 |

| 76 |

KRYTOX 240AB |

FS452 |

| 78 |

CHEVRON SRI |

FS545 |

| 86 |

MOBIL 28 |

FS381A |

| 95 |

MOBILTEMP SHC 32 |

FS612 |

| 115 |

ISOFLEX TOPAS NB52 |

FS737 |

| 125 |

FERROCOTE 5856 BF |

FS639 |

| 149 |

ISOFLEX TOPAS NCA15 |

FS883 |

| 160 |

AEROSHELL 22 |

FS381B-P |

| 161 |

KRYTOX 240AC |

FS433 |

| 162 |

ISOFLEX NBU 15 |

FS637 |

| 167 |

WINSOR LUBE L1018 |

FS179A |

| 169 |

PQ CORROSION PREV. |

FS216 |

| 422 |

ISOFLEX SUPERLDS18 |

FS735 |

| 436 |

ANTICORIT L-245XBF |

FS890 |

| 443 |

ISOFLEX NCA 15 |

FS905 |

| 456 |

MOBILITH SHC15 |

FS919 |

| NA |

LUBCON L252 |

FS915 |

NLGI

consistency

number |

ASTM worked (60 strokes)

penetration at 25 °C

tenths of a millimetre |

Appearance |

Consistency food analog |

| 000 |

445-475 |

fluid |

cooking oil |

| 00 |

400-430 |

semi-fluid |

apple sauce |

| 0 |

355-385 |

very soft |

brown mustard |

| 1 |

310-340 |

soft |

tomato paste |

| 2 |

265-295 |

"normal" grease |

peanut butter |

| 3 |

220-250 |

firm |

vegetable shortening |

| 4 |

175-205 |

very firm |

frozen yogurt |

| 5 |

130-160 |

hard |

smooth pate |

| 6 |

85-115 |

very hard |

cheddar cheese |

Thread issues

Recommended torque

Wrenches - fixed https://www.hoffmann-group.com/US/en/hus/Modular-machining/Indexable-milling-cutters-GARANT/Torque-screwdriver%2C-fixed-setting/p/211750?tId=281

Thread repair

Keenserts https://www.carrlane.com/product/threaded-inserts

Bolts work good for relocating a thread but for larger holes a

steel plug with Dutchman pins to lock

the repair plug in place.

Easily confused

threads

Key problem is that M10x1.0Keg thread is EASILY confused

with 1/8"NPT! 1/8"NPT is 27TPI - which works out to a pitch in the

metric world of 0.94MM which is close to the 1mm in M10x1.0Keg

threads. Keg comes from the German 'kegel' which means 'cone' -

thus tapered.. This easy confusion has led to 'No End of

Bad-Things'™

Painting

Improve wetting

Do wetting test

4 - ways to prep:

Comet cleanser

Sandblast if possible

Heat to 250-300C

Clean with TIG torch

All will no longer wet after a few hours. Wonder if this

helps with powder coating as well?

Degreasing and

stripping - rust removal

Solvents are a poor choice -

Best with an ultrasonic tank TSPP(Tetra-Sodium-Pyro-Phosphate)

will clean what the deodorized kerosene solvents leave behind. This

forms a Basic solution - (just 1% gets one a pH around 10).

TSP(Tri-Sodium-phosphate) gets one to 1 pH of about 12 in a 1%

solution. One can remove even paint with it in a strong warm

solution. (Also used as a hard-soldering flux)

Both TSPP and TSP can attack aluminum - so you would want to be

quick and rinse well -

Purple power degreaser (wallymart)

Flash rust does not occur if the wetted surface is above Ph 8.2 or

so..

Citra-strip?

evaporust

Citric acid + sodium carbonate (Na2CO3)

-> Na₃C₆H₅O₇ ( Trisodium citrate) rust removal

1000ml water. Add 100g Citric acid. dissolve completely. Add 40g of

washing soda (Sodium Carbonate) This will produce a reaction. Test

with litmus paper for neutral. After the reaction subsides add

50ml dish soap or Simple Green (Surfactant) as a wetting agent.

Powder coating

Columbia coatings http://www.columbiacoatings.com/

DIY

powder coating 230C

Chrome http://www.columbiacoatings.com/store/p/1118-All-In-One-Chrome.aspx

powder on hot will fill holes..

Rust prevention

Storage coatings

Camphor in the tool chest

Boeshield - spray on wax.

Cold bluing

Clean and damp and warm - use RO water - active surface?

JAX makes gal jugs of it.

Hot bluing

Boric acid + mineral spirits paste - heat to red quench in oil -

polish

Heat over brass chips - blue and repeat

Clean and clean with 'rodico'

Thick brass box with brass shavings to make even heat.

Glass bead cabinet

150 micron

Makes surface wetable - good for painting

Tacoma upgrade kit for harbor freight cabinet http://www.tacomacompany.com/

Diamond coated glass - checkout scanners

70u after heat treatment aloxl

Files Vallorbe Swiss Habilis precision file http://www.vallorbe.com/en-ch/products/files/habilis-files

Diamond like coated glass:

Honneywell part numbers:

46-46807- Diamonex Platter for compact (420mm) (16.5") StratosH 2322.

46-46806- Diamonex Platter for full-size 508mm (20.0") StratosH 2320/2321.

46-00233 - Diamonex Platter - Compact Stratos 2421

46-00234- Diamonex Platter for sub-compact (353mm) (13.9") Stratos 2422.

46-00296- Diamonex Platter with lift handle for compact (399mm) Stratos 2421.

46-01085 - Diamonex Platter - 508mm StratosMS2430-105KD-US.

46-00235- Sapphire Platter for compact (399mm) Stratos 2421.

46-46809- Sapphire Platter for compact (420mm) StratosH 2322.

46-46808- Sapphire Platter for full-size (508mm) StratosH 2320/2321.

46-00236- Sapphire Platter for sub-compact (353mm) Stratos 2422.

46-00297- Sapphire Platter with lift handle for compact (399mm) Stratos 2421.

46-01127 -Sapphire Platter for StratosS and 2421 (399mm) with 3 flip ups.

Bandsaws

Chinese

Thing Everyone has

6-8 tooth (Stephan)

1/2 x 0.025 x 64-1/2 in. - AKA 5' 4.5" silly legacy units

DM2 (DieMaster-2) - bi-metal - 0.025

Skil 3386

length 150.5 151mm [59-1/4 - 59-1/2]

Bimetal in 9.5mm [3/8"] for metal - not including steel.

Roll-In Band Saw -

Model EF1459

Dream machine

Clamps

Holex Universal clamp (kant twist but better) https://www.hoffmann-group.com/PT/en/hop/Hand-and-assembly-tools/Clamps/c/86

Die / spindle

Grinder

BIAX make air powered 60k -100k RPM Biax? only air -

top end 85-100krpm

NSK pencil grinder dr-500 (Edge precision)

https://proxxon.com

- only goes up to 20k rpm - good dremel replacement TIR=

50um

https://store.cncstepusa.com/products/kress-1050-fme-p

kress

1050 FME-P runout of max 10um guaranteed.

https://www.nsk-nakanishi.co.jp/industrial-eng/mgt/emaxevolution/

Stephan's latest IR-310 https://www.artcotools.com/nsk-nakanishi-ir310-ring-type-attachment.html

Spindle air

grinder

PLANET 600 Air Turbine Spindle - 65,000 TIR = 1um

!! ($1000+ used as of 2020) rpm http://www.nskamericacorp.com/product/category/planet/28?AspxAutoDetectCookieSupport=1

Continental Diamond Tool Corporation https://www.cdtusa.net/

CBN grinding tools..

http://professionalinstrumentscompany.com/products/rotary-motion/air-bearings/

Air Turbine 602JS 40-90krpm TIR = 10um

U2 grinding

machine

Chucks

Rohm the best?

Albrecht chucks keyless look very good

ER Collets Notes

ER(Extended Range) originated by Rego-Fix - Swiss

company - originated in 1976.

The collet HAS to be snapped in before tightening.

Do not use the backup screw to set length - it is tightened AFTER

the collet.

ER Torque

collet size

|

Torque

recommended

|

Torque

max

|

Wrench

size

|

Range

|

ER8

|

|

|

|

|

ER11

|

|

|

|

|

ER16

|

28 Nm

|

50 Nm

|

25 mm 24.5?

|

1 -10mm

|

ER20

|

|

|

|

|

ER25

|

|

|

|

|

ER32

|

70 Nm

|

105 Nm

|

45 mm

|

2-20mm

|

ER40

|

120 Nm

|

150 Nm

|

57 mm

|

3-26mm

|

ER50

|

|

|

|

|

Metrology

Indicator Stands

The best surface plate indicator stand is the Murkens

tool (What Herman Schmidt sold and then copied). http://murkensprecisiontool.com/indicatorbase.html

Magnetic bases are not all the same. Be sure to look at the

pull strength. Often it is best to mill a flat where the main

rod screw in to make a stiffer joint - perhaps a copper crush

washer? And while you are at it, increase the diameter of the first

rod.

The Noga style arms have a trick for those new to using them - the

joints get tight one at a time as you tighten it. Still a bit

fiddly to use and they are not perfectly rigid.

Repeatometer

low carbon precision ground stock 1/2 x 4 x 11.75

The silicon nitride ball is 0.1875" diameter and is glued in a ball

milled pocket.

Flatness by

process and example - approximate

- Milling 10um

- Surface grinding 2um

- Commercial optics - 2.5um - spectacles - prisms

- Scraping cut - 2um

- Surface-plate - 2 - 8um - best small 900nm - light wave

length

- High quality optics 250nm -

- Gauge block flatness - 100nm - ability to wring ..

- Red light 600nm - 632.8nm popular red neon line

- blue light 450nm

- lapping 30nm - close to 1/20 wave

Scraping

Scraping cut - 2um

Normally cast iron.

DIY scraping tool inserts:

3/4 x 3/4 x 3/16

1/2 x 1/2 x 1/8

bar 3/16 x 3/4 cold rolled flat bar

M6 screw holding?

1/8 x 1/2 x 1" USA-Made C2 carbide blanks - MSC # 04120754 or

better carbide processors

Scraper blades are usually straight C-2.

Pin pointing scraper

https://youtu.be/QUtH8Wkhrw4?t=2804

Blade for scraping carbon-steel as per Alex Fillafer

Surface Plate

notes

Inking

Spotting ink - charbonnel aqua wash https://www.dickblick.com

PRussian blue

primrose yellow

cardinal red

Robin renzetti says 50:50 charbonnel/Canode mix in a syringe is the

bomb- use with latex rubber rollers.

Support blocks

for surface plates

Bessel points located .2203 X L from each end --- .5594 x L apart -

equalized deflection by gravity - middle and ends

Airy points = no slope at ends 0.21132* L from each end or .57736

apart

That being said - I think using 3 points under a surface plate

ignores reality. A somewhat compliant flat material that

supports the plate all over will allow the plate to hold more weight

without bending. Anyone can load this up in a CAD system and

run FIA to see the truth.

Materials in

plates

SiO2 In the form of Alpha-quartz (7moh) - 5.5 x 10-7 /°C

= This coefficient is 1/34 that of copper and only 1/7 of

borosilicate glass.

SiC - 4.4X10-6/°C

Cera Zero 826HV *

Possible treatment

to make black plates surface wear better

There is a technology used on concrete floors - sodium

silicate(water-glass) is applied as a densifier (sometimes lithium

silicate) - then diamond polished to a shinny surface.

Black surface plates are stiffer, but softer surface.

I propose coating the surface with sodium silicate to provide a

harder wear surface - then lapp flat again. Could be it will

be too smooth - cause wringing problems?

Setup blocks

Setup blocks

20x40x60mm

Renzetti hole pattern 6mm thread

Squish-test

Plastigauge - -- I have used multicore solder with accurate

results as well. Just squish the solder - measure with

micrometer.

Temperature

Thermochrom temp crayons.

Using Straight

edge

There is more to this than meets the eye(pun intended).. See http://what-when-how.com/ology/straight-edges-metrology/

Plastics and

similar materials

Ren Shape 5045 is our highest density polyurethane

foam board - sacrificial plate for routing - etc.

PTFE(teflon)

Epoxy epi- + oxy Epoxy - bisphenol A diglycidyl ether (Bisphenol is

a phenol) - there is a strained triangular ring - with an oxygen

(the oxy of epoxy) and two phenol rings (Phenols like to bond to

everything (thus why rather than their so-call antiox properties -

they bond to metals preventing absorption)).

TPU92A - filament - o-rings etc. Flexable

PLA - brittle

PETG (PET - Glycol-modified) - good layer adhesion - Lower

temp

Nylon Strong

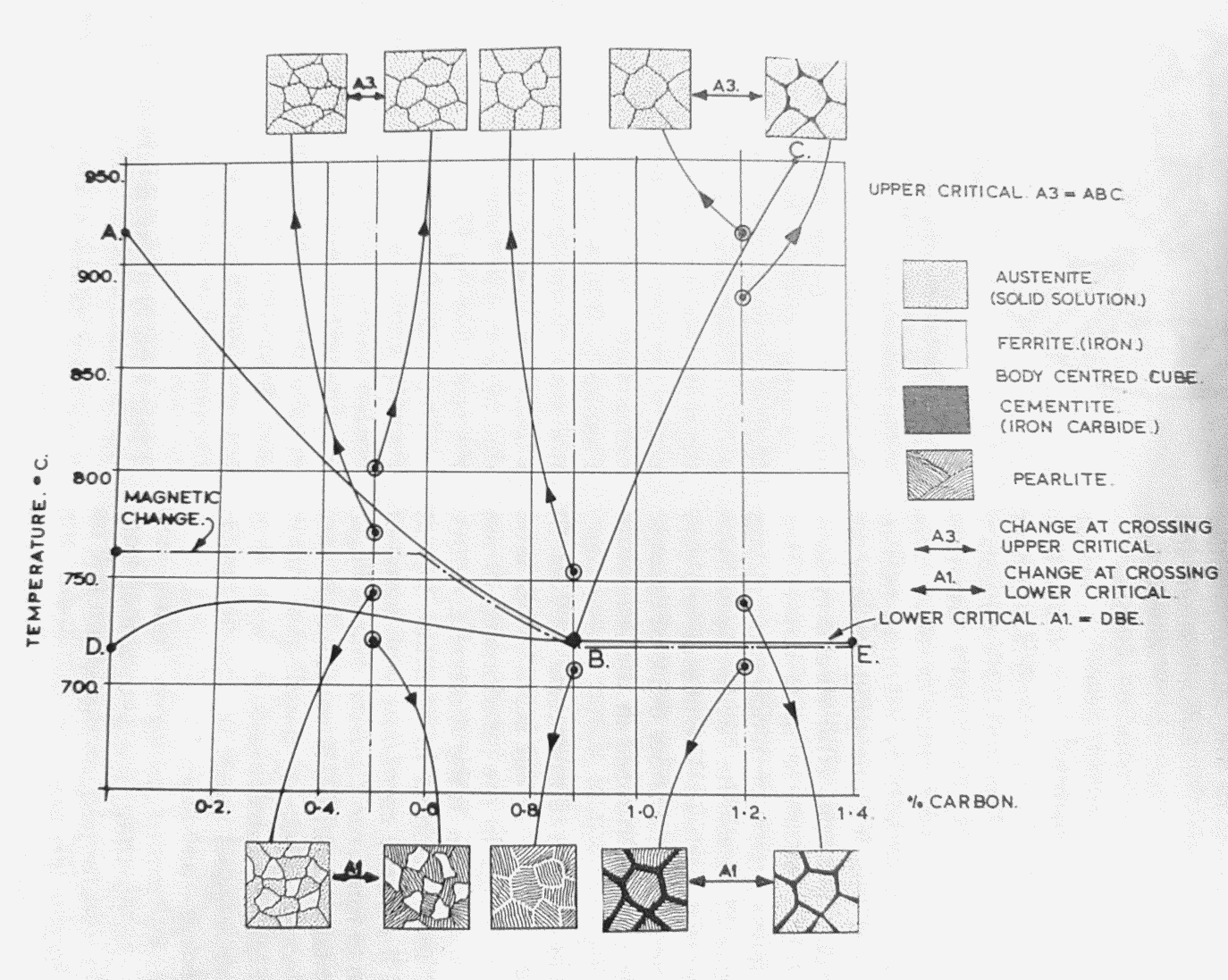

Metals

Detect, identify

metal type - end-paint color codes

Hit with hard knocker:

Steel will go RINGGGGGGGGGgggggggg.......

ductile iron will go DING..

cast iron will go THUD.

https://www.europa-lehrmittel.de/tm47

Detect cast iron from cast steel - dust vs chips

01 tool steel = drill rod

Grinding tests - White, pink, ruby-red, or beige colored wheels work

best - not the cheap black ones

See spark-tests

Carbide is heavier than HSS - 14-15g/cm^3 vs a little less than

8gm/cm^2

End paint color

codes

There is more than one standard.

Not a good idea to rely on it. Often found on end of bar stock.

Sources

Special alloys

http://www.nealloys.com/

https://www.frysteel.com/products.php

Cast iron

Durobar is much the same - machines better - better finish - MUCH

more expensive than regular cast-iron.

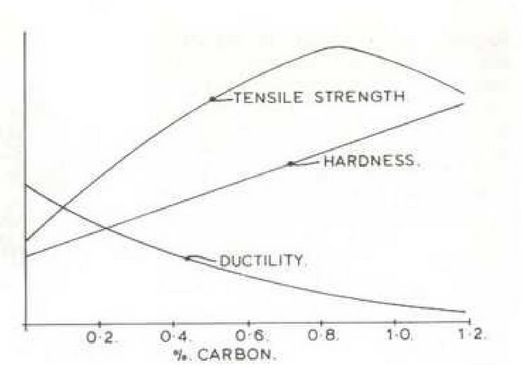

Steel

Most common steels

1020 gummy mild steel

4140

O1

D2

A2

Mild Steel

1018 has a higher manganese content than certain other low carbon

grades, such as 1020. With higher manganese, 1018 is better steel

for carburized parts, since it produces a harder and more uniform

case. It also has higher mechanical properties and better

machinability due to the cold drawing process

ALLOY STEEL

Steel grade cross reference - Which standard to use? Din

W-Nr(Werkstoff-Number) - SAE/ANSI ???? Have a Material Cross Reference List

pdf Just a start..

Need to make a table - columns - SAE - W-rn DIN Description

O1 Drill rod (oil hardened) - 115CrV3 DIN 1.2210 / 115CrV3

4140 - DIN 1.7225

A2080 tool steel

DIN 1.2080 tool-steel (D3) - X210Cr12 D3 is an oil hardening,

high carbon/chromium type tool steel with very high wear resistance.

It hardens with a very slight change in

size. The alloy possesses very high compressive strength and is deep

hardening.

DIN 1.2379 tool steel (D2) - X 153 CrMoV 12

≈ 720 N/mm² high-alloy steel for through-hardening with

moderate machinability; extremely wear resistant and low warpage,

good dimensional stability, toughness and through hardenability

A2 - A2 Tool Steel | 1.2363 | X100CrMoV5

A2 Tool Steel is a versatile, air hardening chromium alloy tool

steel that replaces O1 tool steel when safer hardening, less

distortion and increased wear resistance are required. AISI type A2

steel is intermediate in wear resistance between O1 oil-hardening

tool steel and D2 high-carbon, high-chromium tool steel.

Toolox® 33 is a prehardened steel suitable for tools and engineering

components. It possesses good dimensional stability after machining.

Delivered in quenched and tempered condition, Toolox® 33 features

high impact toughness and very low residual stresses to achieve good

dimensional stability after machining.

C45 (1045) Steel for making medium carbon tools.

4037 - dowel pins

https://www.steelforge.com/alloy-steel-4037-aisi-4037 Molybdenum

Din 100Cr6 ball bearing steel SAE 52100

DC-53 Tool Steel

Din W-Nr(Werkstoff-Number) e.g. 1.4404 ( this would be an AISI

SS316L, DIN X2CrNiMo17-12-2, UNS S31603 etc.

- Higher hardness (62-64 HRc) than D2 after heat treatment

- Twice the toughness of D2 with superior wear resistance

- Substantially higher fatigue strength compared to D2

- Smaller primary carbides than D2 protect the die from

chipping and cracking

- Machines and grinds up to 40% faster than D2

- Less residual stress after wire EDM

8620 20NiCrMo2-2 C=.2% Mo=.2% is a hardenable chromium,

molybdenum, nickel low alloy steel often used for carburizing to

develop a case-hardened part.

Alloy composition (by weight)

| SAE grade |

% >Cr |

% Mo |

% C * |

% Mn |

% P(max) |

% S(max) |

% Si |

| 4118 |

0.40–0.60 |

0.08–0.15 |

0.18–0.23 |

0.70–0.90 |

0.035 |

0.040 |

0.15–0.35 |

| 4120 |

0.40–0.60 |

0.13–0.20 |

0.18–0.23 |

0.90–1.20 |

0.035 |

0.040 |

0.15–0.35 |

| 4121 |

0.45–0.65 |

0.20–0.30 |

0.18–0.23 |

0.75–1.00 |

0.035 |

0.040 |

0.15–0.35 |

| 4130 |

0.80–1.10 |

0.15–0.25 |

0.28–0.33 |

0.40–0.60 |

0.035 |

0.040 |

0.15–0.35 |

| 4135 |

0.80–1.10 |

0.15–0.25 |

0.33–0.38 |

0.70–0.90 |

0.035 |

0.040 |

0.15–0.35 |

| 4137 |

0.80–1.10 |

0.15–0.25 |

0.35–0.40 |

0.70–0.90 |

0.035 |

0.040 |

0.15–0.35 |

| 4140 |

0.80–1.10 |

0.15–0.25 |

0.38–0.43 |

0.75–1.00 |

0.035 |

0.040 |

0.15–0.35 |

| 4142 |

0.80–1.10 |

0.15–0.25 |

0.40–0.45 |

0.75–1.00 |

0.035 |

0.040 |

0.15–0.35 |

| 4145 |

0.80–1.10 |

0.15–0.25 |

0.43–0.48 |

0.75–1.00 |

0.035 |

0.040 |

0.15–0.35 |

| 4147 |

0.80–1.10 |

0.15–0.25 |

0.45–0.50 |

0.75–1.00 |

0.035 |

0.040 |

0.15–0.35 |

| 4150 |

0.80–1.10 |

0.15–0.25 |

0.48–0.53 |

0.75–1.00 |

0.035 |

0.040 |

0.15–0.35 |

| 4161 |

0.70–0.90 |

0.25–0.35 |

0.56–0.64 |

0.75–1.00 |

0.035 |

0.040 |

0.15–0.35 |

| * The carbon composition of the

alloy is denoted by the last two digits of the SAE

specification number, in hundredths of a percent |

C1084 - forging steel - rail track

ANCI C1060 - medium carbon steel C = .55-.65 Mn 0.6-0.9 P

.04max S 0.05 max knuckle pin

TOOLOX 33 - quenched and tempered tool steel designed to have low

residual stresses. It is characterized by its extremely good

machinability and is pre-hardened to 33 HRC.

Gauge blocks are made of 52100 (chromium alloy steel ) tempered to

66 Rc W-nr. 1.3505 - DIN 100Cr6

A6 Cams

M2 Dills/end-mills (HSS?), kinives, taps

S2 bolt cutters, wrenches

S5

S7 Cams,

O2 taps

O6

L6 15n20 - (1075 +2% nickle) chisels, hammers, screw

drivers, wrenches

W2 files

AN25

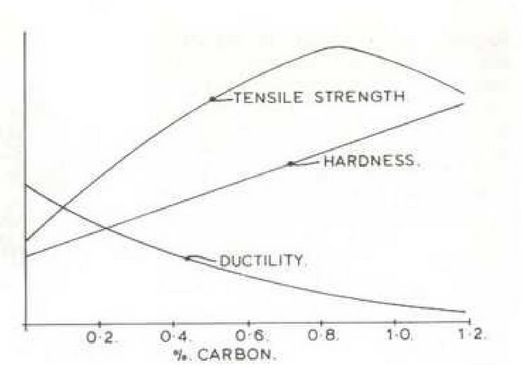

In 10xx - the xx stands for the hundredths of a percent carbon. 1020

- would be 0.20% carbon

Framing nails 1008/1010/1018

1018 - most common grade

1020 -1030 railroad spikes, brake lever,

1040 - bolts, connecting rods, tubing

1050, and 1541H - Car axles below 1.625"

1060 Snap rings, railroad knuckle pins

1070 cluch disk,

1075-1095 - carbon kitchen knives - will rust - but get sharp.

1084 or higher - Railroad tracks.

1085 mower knives, music wire?

1095 - clock-spring-steel - Usually tempered blue - some drywall

knives

1145 - Ujoints

2330 heat treated bolts

3130 Steering ARm bolts

3115 transmission gears

4042 Steering arms

4063 coil springs - car

4140 - 4145 hydraulic ram, transmission shafts

440C Corrosion resistant ball bearings.

4815 heayduty bolts

5160 is used to make leaf springs, coil spings-truck, scrapers,

bumpers, flexible knife edges.

52100 Ball bearings

carbon steel razor blades - about 1.2% carbon

For Machine shafts

and parts - hardening etc

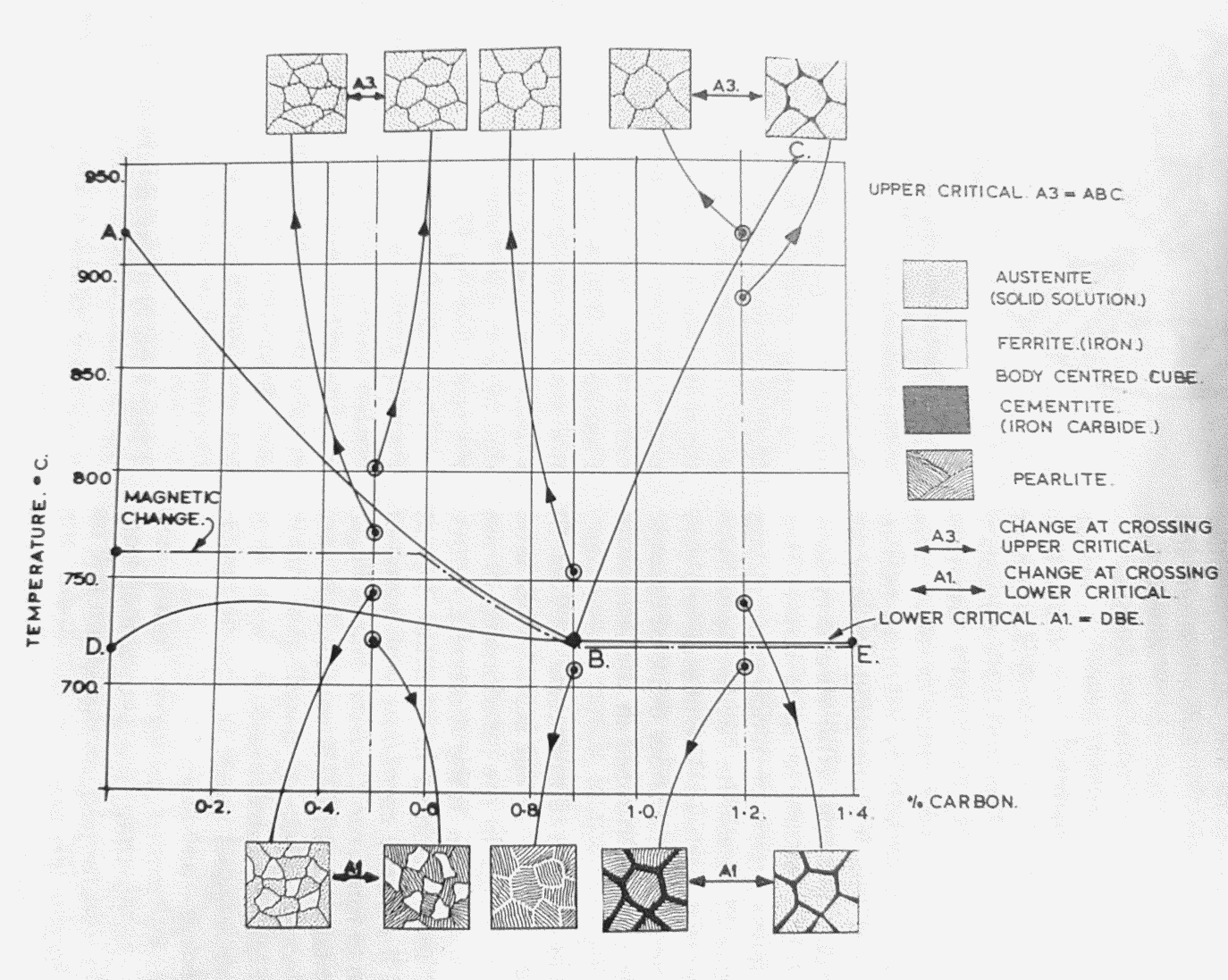

When you want tough materials that will see high tensile stresses,

loads in alternating directions and magnitudes, you're going to have

to rely on heat treated carbon or other alloy steel.

SAE8620 or equivalent is good - harden (carburize) prior to

grinding.

SAE4150 machined in an initially normalized condition. If you

subsequently harden and draw to HRC 40-42 -- tough and strong.

Precise bearing fits on the spindle, need finish grinding to size.

Bearing fit will be depend on type of bearings used.

Hang shafts when heat treating. When quenching, dip quench AXIALLY

to avoid the risk of bowing/bending the part.

Surface hardening puts the subsurface into a compressive load which

enhances strength and toughness. Explains why gears are often made

of carberized and hardened 4820 or 8620 or 9310.

8620 makes EXCELLENT gears and shafting material. It is both tough

and wear resistant, especially when deep carbuized. It is also

relatively inexpensive. For really GOOD stuff, ask for AQBQ grade

(aircraft quality, bearing quality). This stuff is comparatively

void and stringer free. It also comes with material certifications

that the imported crap doesn't have.

To really optimize stress reduction/minimization in a part:

1. Stress relieve at 1200F for 1-2 hours at heat prior to heat

treating. Furnace cool if possible.

2. Carburize while standing on edge or hanging in furnace to

minimize warpage.

3. Quench via axial dip as opposed to laying on side while

quenching.

4. Double temper prior to grinding

5. Stress relieve at 250-300F after finish grind.

6 - to selectively carburize use copper plating (about 50um

thick) before carburizing.

See

Hardening, tempering

and heat treatment. Workshop practice series

Heat treating -

carbonizing

plasma carbon nitriding

(temper)

vacuum temper, deep freeze - service from Solar Atmospheres

One can mix boric acid with methanol - heat part in steel bowl -

then quench bowl and all - no scale to speak of. A thinner mix

can be used to coat parts.. Borax is NOT boric acid.

Hardness

Rc hardness. Tool

42 Socket head cap screw

49 scales - metal rulers

49 screwdriver blade

50 hex wrench

55 lock-in pliers

56 pocket knife blade

58 height scribe blade

58 barbers razor blade

59 dowel pin

65 file

65 high speed steel

79 micro grain carbide

Stainless

Minimum of 10.5% chromium. The chromium forms a protective oxide

film on the surface - very thin (2-3 nm).

Ferritic - (Cr 12.5 -17%) mostly nickel free - not heat treatable -

weldable(thin) - magnetic

Martensitic (C - 0.2-1% Cr 10.5-18%) Heat treatable - magnetic -

hard to weld - can get brittle

Austenitic (Cr 16-26% Ni 6-12% +) Most common - non hardenable

- work hardenable - weldable mostly non-magnetic

Duplex (Cr 18-26% Ni 4-7% Mo 0-4% cu ) magnetic,

http://www.sidecuts.com/

Sheet steel stock gauge 18 and 10

Stainless sheet 17-7 - easy to harden

Martensiticstainless steels can be heat treated and hardened, but

have reduced chemical resistance

ISO14305 (AKA 303)most easy to machine austenitic grade of stainless

- has Sulfur for machine-ability.

https://titussteel.com/our-products/mold-and-die-steels/tool-ox-33/

Brass

Online metals has several types

360 brass Zn35.5 Fe 0.35 Pb 2.5-3.7 - most common of rod and bar

Bronze

Aluminum Bronze

642

This is a great material that is harder than Aluminum or bronze and

machines well. We have used it for a great number of projects. Is an

excellent material for valve stems, gears, marine hardware,

pole-line hardware, bolts, nuts, valve bodies and components,

mechanical parts

Gilding metal

cu90 zn10 - annealed rockwell-F 53

copper

hadness - annealed 40HV - hard 110HV

Aluminum

356 - used for casting..

Higher the number the stiffer the aluminum -

7075 - quite strong - but poor to weld

cutting tools

Feeds and speeds

Feeds: Cutting speed or surface speed or speed - tooth tip speed

= Vf

Speeds: Feedrate or feed - table speed

Surface finish - to improve from most to least effective -

increase surface speed - increase depth of cut - increase feed

rate

From tool/insert

data - printed on package is Fz and Vc

we can calculate n(spindle speed) and Vf (speed

of table.

Fz or Ft = Feed per tooth (chip

load) in mm = MMPT (millimeter/tooth) (imperial

IPT Inch per Tooth)

Vc = m/min (cutting speed - tip of tooth speed)

in m so don't confuse with millimeter mm!!! SMM Cutting

speed - surface-distance-per min

D = tool diameter in mm (in turning - workpiece diameter )

n = rev/min as in RPM becomes S-code

- n = 1000 ·Vc / D · π · n Simplifies to Vc

318/D

Vf or Fm = table feed = velocity of

table MMPM (Millimeters per minute) (endmill) in

mm/min Table feed this is the F-code

Where:

Z or N= number of teeth or flutes

n = Vc · 1000/π · D · n

Vf or Fm = table feed = feed rate =

velocity of table MMPM (Millimeters per minute)

Ae = width of cut or Radial depth of cut

Ap = Depth of cut, Axial Depth of cut.

D1 = diameter of shaft without the flutes.

Chipload = feed per tooth

n = rev/min as in RPM n = Vc

1000/D π Simplifies to Vc 318/D

Fn = Feed per rev as in MMPR (Millimeters Per

Revolution)

SMM Surface meter/min (imperial SFM (surface Feet per

min)) = π D n

Vc = π · D · n /1000 (1000 is to

convert m to mm)

Fz = Vf / Z · n

Vf = Fz · n (drill)

f = feed per rev (mm/rev)

Cutting feed (m/rev) x spindle speed (RPM) = feed

rate m/min

End-mill plunge rate = feedrate/flutes

Q = material removal rate (cm3/min)

Ra = surface roughness (μm)

hm = average chip thickness. = fz (Ae/D1)1/2

For best surface finish - step-over should = feed per

tooth.

Spotting drill

Some use a split carbide with a point angle to match the drill.

Some use a pyramid point carbide (the math to get the angle right

is harder). Both of these are similar to the points used for

engraving, but the spot drills are of much larger diameter - all

are stubby.

Boring heads

WOHLHAUPTER boring head -

Schmidt makes small ones http://www.schmid-praezision.de/eng/?Products-and-Service/Facing--and-Boring-Heads/UBS-Universal-Facing-and-Boring-Head

ausdrehkopf

Iscar DR-MF-08R-2.25D-12A-04 https://www.iscar.com/Products.aspx/CountryID/1/ProductId/4906

What Peter Stanto uses - actually a d'andrea rebranded.

$500-$700/2020

Inserts

Lots of suppliers - Mil-Tec inserts - might be the best?

S-PS-032-5-2TA -- PS032-MTC357A2 ph(800) 564-5832

Insert Size and

shapes

ANSI vs ISO - The

codes will confuse you

Particularly the number bit - the first letters can be exactly the

same - but for instance - an ANSI CDE322 works out to be a ISO

CDE160308. In a sane world, the codes would put the most

variable parts at the end - so Shape, dimensions - then angles -

then tolerance and grade codes would have PMK codes embedded....

Well we don't live in a sane world.. There are extra letters added

by some makers to make sure you stay confused.

See insert

codes for details or this chart with ISO, ANSI, and tool holder

codes.

This table

helps one translate ISO numbers with ANSI numbers.

Current Insets

S20R-SCLCRO9 (Insert CCMTO09T304)

SNRO020R16 (Insert 16IR AG60)

SER2020K16 (Insert 16ER AG60)

SDNCN2020K11 (Insert DCMT11T304)

SDJCR2020K11 (Insert DCMT11T304

MGEHR2020-3 (Insert MGMN300)

SCLCR2020K09 (Insert CCMTO09T304)

WWLNR2020K08 (Insert WN □ □ 0804 □ □ )

Find a boot-leg copy of ISO-1832-2017 for the latest bits.

And here is an example of the Old ANSI standard

CDE 322R05

|C 78 or 80° shape

||D 15° clearance angle

|||E Tolerance

||| - blank

|||||3 3/8" inscribed circle

||||||2 2/16" thickness

|||||||2 2/64" radius

||||||||R Right hand

|||||||||05

DCMT and CCMT are shapes- Details here http://www.carbidedepot.com/formulas-insert-d.htm

holders

Lathe cut-off

Iscar SGFH 26-3 Uses Insert : GFN/R/L 3

Lathe others

Cutting tool

materials

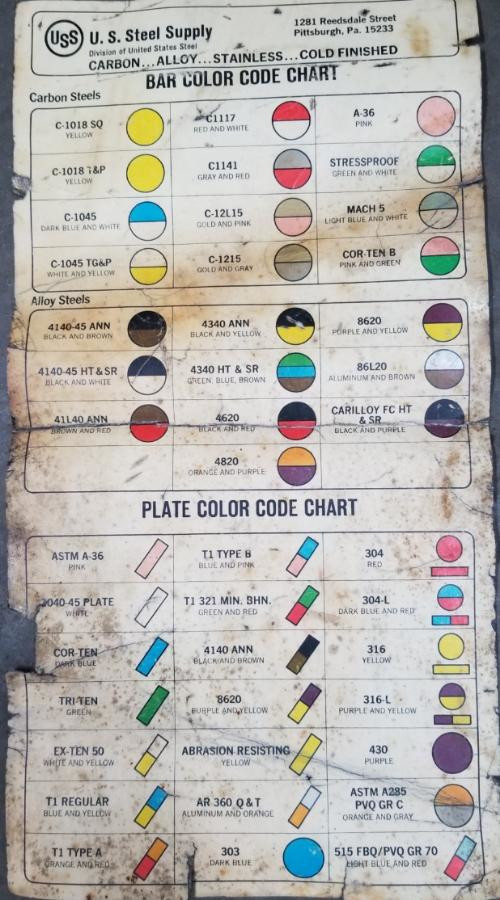

Inserts Carbide

PCD Poly Crystalline diamond aluminum and copper

CBN Cubic Boron Nitride - really hard - harder than diamond at

high temperature. Can actually machine sintered carbide to some

extent.

Carbide" is mostly Tungsten Carbide (WC) sintered with cobalt as

a glue to hold it together. - Straight grades (C1, C2, C3, C4) are

tungsten carbide. C5 through C9 are alloyed grades containing

titanium carbide, niobium carbide, tantalum carbide and a few

others also in varying percentages. Each added for certain

characteristics and often only 1 to 5 percent of each. These are

also know as "steel cutting grades" while the C1-C4 numbers are

sometimes called "cast iron and/or aluminum" grades. C-8 or 9 may

be 25% or more TiC so pushing a cermet. Grades above C-9 are

special use and mostly straights. You see them in hammers, dies

and such.

| Tungsten Carbide Standard Grade Chart |

| Industry Code |

FCC Grade |

Binder Content & Type |

Hardness (Ra) |

Hardness

(HV30) |

Density (g/cm3) |

Minimum Transverse Rupture Strength (psi) |

Grain Size |

| General Purpose Grades |

| C2 |

FC3 |

6% Co |

92.0 |

1585 |

14.95 |

320,000 |

Fine |

| C1 |

FC4 |

7.5% Co |

91.0 |

1460 |

14.70 |

330,000 |

Fine |

| Metal Forming and Wear Grades |

| C10 |

FC10 |

9% Co |

90.0 |

1360 |

14.60 |

360,000 |

Medium |

| C11 |

FC11 |

12% Co |

89.5 |

1315 |

14.30 |

390,000 |

Medium |

| C12 |

FC12 |

15% Co |

88.0 |

1190 |

14.00 |

420,000 |

Medium |

| C13 |

FC13 |

20% Co |

85.0 |

955 |

13.60 |

450,000 |

Medium |

| C14 |

FC25 |

25% Co |

83.2 |

760 |

13.15 |

435,000 |

Medium |

| Submicron Grades |

| C3 |

FC3M |

6% Co |

93.0 |

1740 |

14.95 |

375,000 |

Submicron |

| C2 |

FC10M |

10% Co |

91.9 |

1570 |

14.50 |

450,000 |

Submicron |

| C1 |

FC12M |

15% Co |

89.5 |

1315 |

14.00 |

530,000 |

Submicron |

| Rotary Drilling and Mining Grades |

| C11 |

FC10C |

10% Co |

88.6 |

1240 |

14.50 |

400,000 |

Coarse |

| C12 |

FC11C |

10% Co |

87.8 |

1175 |

14.50 |

425,000 |

Coarse |

| Corrosion Resistant Grades |

| - |

FC3N |

6% Ni |

91.0 |

1460 |

14.95 |

275,000 |

Fine |

| - |

FC10N |

9% Ni |

89.5 |

1315 |

14.60 |

290,000 |

Fine |

| - |

FC8N |

8.5% Ni |

91.5 |

1515 |

14.50 |

300,000 |

Fine |

| - |

FC82 |

15% Ni+Co |

89.9 |

1355 |

9.00 |

310,000 |

Fine |

C6 - common

|

|

|

|

|

|

|

|

C1: Good wear resistance, nonferrous drawing, light blanking

dies, mandrels, wear rings, high pressure parts, wood working

blades, valve stems and seats, knives, bearings, grippers and

guides.

C2: General Purpose wear resistance, where only light shock is

encountered; small dies and mandrels, nonferrous wire and tube

drawing, nozzles, seal rings and powder compacting dies.

C3: High abrasion resistance, little shock resistance; small

drawing dies, coating and compacting dies, bushings, machines

parts and valve parts.

C4: Hardest grade, high wear resistance, no shock or impact

encountered; wear bushings and nozzles.

Cermet is a composite material composed of ceramic (cer) and

metal (met) materials.

CBN

MKD

(Monocrystalline Diamond)

Insert screws

; CDE322 takes a 60° flat head 6-32 - slightly less than

0.5". This is notated as SE-02-01 or SE-02-11 - the last

number is something about the length - but not clear what.

Wish I knew where to find the standard this is all based on.

Grades

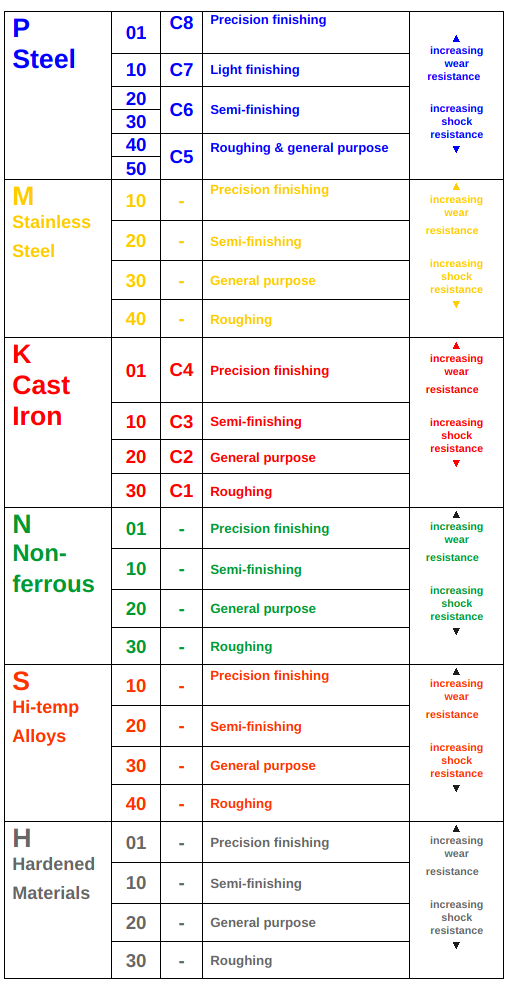

First understand the PMK codes:

See machine reference folder

Sandvik codes start with GC ( Grade Code)

We update the second number when a new generation is created, so

for the 3020 it would now be 3220 or GC3220

GC3040 also cast iron.

H13A non ferris

https://www.sandvik.coromant.com/en-us/products/pages/milling-inserts-grades.aspx

https://www.ingersoll-imc.com/support/milling-grades

https://www.ingersoll-imc.com/support/turning-grades-cross-reference

https://www.sumitool.com/en/downloads/cutting-tools/general-catalog/assets/pdf/GC_A_en.pdf

https://www.machiningdoctor.com/grades/grades-finder/

https://www.cets.com/resources/kennametal-grade-descriptions.html

This table can help cross

insert grade codes.

Ingersol old

codes

Some crosses

https://www.widia.com/us/en/resources/conversion-guide.html

IN2505 P20-P30 M20-M40 K20-K30 N10-N30 S20-S30 H10-H30

IN2530 P20-P50 M20-M40 S20-S40

10K - H13A - K

102 KNSM20-M40, P20-P50, S20-S40

108 PMS

Grade 111 --> IN10K - K

227 P-M-S

305 P

501 K

511XL P

555 P-M-S

6510 K

6530 P25-45 M25-40

581 à IN1530 à IN2530 PM

205 à IN15K cast iron but HiPos lines went to IN30M -

N

301 à IN5530 à IN6530 à IN2530 P

919 CVD coated - 20 years old. likely something like what would

eventually become IN6510 or IN6530 K

IN2515 would be the cast iron grade K?

IN15K N

ISCAR codes

IC70 P15-25 c6

IC350 P10-20M K10-30

IC354 P20-40 M10-30 KNSH

IC328 PMS

IC656 P20-40 MKSH

IC907 P10-30 M5-20 K15-30 H05-15 S05-20 N05-20

(Iscar SGFH 26-3 Uses Insert : GFN/R/L 3)

Mitsubishi

U610 PK

UE6020

PK

US735

VP15TF P20-30 M20-30 K20-30 S10-20

Sandnvik

4325 P

435 P35

H13A N15-30

3020 K15, P15 CVD COATED K(fz 0.10-0.21mm Vc

225-185m/min)H(fz 0.10-0.21mm Vc 45-60m/min)

4015(GC4015) P-1-30 K5-25

5015 P K

Kennametal

CM3

KC725M P30-40 M30-40 S30-40

KC850 P25-45 M30-45 C5-C6

K313 M10-20 K05-20 N10-20 S10-20 C3-C4

KY2100

Korloy

PC9030 intended for M ft=0.05mm/ Vf=90mm/min

Kyocera

TN60 P1-10 M1-10 K1-15

TC60 - PM

Tungaloy

N308 P M

Unknown

YBM251 (ISO Class: P15-P40, M10-M30)

CK251 - appears to be YBC251 P10-P30

Chinese

grades

Coatings

CVD(ChemicalVaporDeposition)

CVD coatings are thick (typically 9 – 20 microns) and highly

wear resistant, making them especially useful for steel and cast

iron machining as well as widely used in turning operations. Such

thick coatings can compromise edge toughness. Good for

turning, milling and drilling applications involving ferrous

materials. In fact, CVD-coated inserts are recommended over

PVD-coated inserts for turning, milling or drilling steels and

cast irons.

TiN Coatings:

Excellent build-up edge resistance

Excellent on gummy materials

Excellent for threading and cutoff operations

Makes it easy to identify what insert corners have been used

Effective at lower speeds

TiC Coatings:

Excellent wear resistance

Effective at medium speeds

Excellent on abrasive materials

Al203 Coatings:

Excellent crater resistance

Effective at high speeds and high heat conditions

PVD (PhysicalVaporDeposition)

PVD coatings are thin (typically 2 – 3 microns) yet tougher and

typically smoother than CVD coatings. Useful for machining

materials, such as superalloys, titanium alloys and

difficult-to-machine stainless steels, that typically notch or

chip cutting edges.

PVD-coated inserts are especially useful for turning, milling and

drilling applications involving high-temperature alloys, titanium

alloys and stainless steel. PVD-coated inserts are recommended

when turning high-temperature alloys; however, if the alloy is on

the softer side and can be machined at higher speeds, a CVD

coating is preferred.

PVD Coating Types:

TiN Coatings:

Excellent built-up edge resistance

Broad application range

Effective on high-temperature alloys

Effective on stainless steels

TiCN Coatings:

Harder than TiN coatings

Effective on end mills

Sometimes used in milling applications where the work material is

abrasive

TiAIN Coatings:

Harder and more stable than other PVD coating types

Becomes harder and more stable with time

Effective on high-temperature alloys and stainless steels

Gears

module-number = outside diameter/ (number-of-teeth + 2) in

mm of course.. To convert to obsolete imperial numbers

= 25.4 /module-number

Bearings

Lip seals create more heat than you would think..

Fasteners

For button head screw - torx-plus is the best - hex drive

fails. Torx-plus should probably be the default for most

socket head fasteners.

CAD And CAM

Robenz robinrenzetti uses solidworks CAD

Stephan uses Autodesk Fusion CAD (pro E at work)- Linux CNC

CAM - BOBCAD - I think alibre ..

Yes: Big step for me, had to pull the trigger on a 3d cam

package to go along with Alibre Designer. Tried different packages

in my price range and talked to several long time users (you know

who you are, thanks!), and I ended up buying Bobcad v32 in 3axis,

Pro version. Already using it to work in customer parts, with

multiple setups. Thanks to the #bobcadafterdark

videos. Time will tell what I got myself into ;)

Pro Engineer wildfire runs on Linux M180 - where to get?

solidworks via EAA - but no Linux so nothing-burger.

Peter Stanton(edge precision) uses ESPRIT what uses for CAM

(over $5k) - CAD - spceclaim http://www.spaceclaim.com

Possible Linux stuff - FreeCAD.

solvespace (limited) - onshape(not free)

3D metal printers

https://www.shapeways.com/

Precision parts to

think about

Misumi miniature

ball slides

Keyless shaft

locking

Misumi KPL300

Ringfedder RfN 8006

Machining Terms /

Terminology

- Face and Flank

- On a cutting edge the face(AKA rake-=surface) is the side

where the chip is formed and the flank is next to the new

surface of what it being cut. There are two flanks on a lathe

cutter - Flank(major) cuts as one feeds in Z - Flank(minor) cuts

as one feeds in X(cross-slide) or plunge cut. The nose

radius is where the two flanks connect.

- Mandrel vs Arbor

- A mandrel holds work, an arbor hold tooling

- Staking

- Punching operation (often with center punch) to deform a part

mostly to capture a part.

- Dutchman

- A hole with pin parallel the shaft at the intersection of a

shaft and hole to prevent rotation.

- Weldon flat

- A ground flat - typically on an endmill that a grub screw

clamps to. See

- Whistle Notch

- A beveled notch that is an improvement on a weldon flat in it

helps resist axial motion. See

- Pawl

- pawl is a movable lever that engages a fixed component to

either prevent movement in one direction or restrain it

altogether. As such, it is a type of latch and can also be

considered a type of dog. It typically consists of a

spring-loaded lever that engages a mating component at a steep

enough angle to restrain it. Pawls are often tapered, being

widened at their pivot for anchoring and narrow at their tip.

- Dog

- a dog is a tool or part of a tool, such as a pawl, that

prevents or imparts movement through physical engagement. Or it

may hold another object in place by blocking it, clamping it, or

otherwise obstructing its movement. A lathe dog transmits rotary

motion from a faceplate to a workpiece mounted between centers

in a lathe.

- Tommy bar or T-bar

- A short rod used as a lever or handle for turning a jackscrew,

socket wrench, or pin spanner wrench by being inserted loosely

in the hole provided for that purpose.

- HSS

- High Speed Steel

- SPFL

- Spiral FluteHSSE

- High Speed Steel with cobalt?

- E11

- ISO 286-2 tolerance class E11

- GH3

- GH3 = Ground High 3 Tolerance class H3

Equipment

Plates and angles

Large Cast iron lapping plate Bush - Milwaukee 18" x 15" ( Grooves

are .078”W(2mm) x .100”D on .531” (13.5mm) centers. )

Lapping plate Challeng machinery grand haven MI 10" x 14"

surface plate Rahn 37230 !4" x 14"

Shars Granite Square - rt angle - 254 mm x 152 mm x 25mm

Surface Plate unnamed 9 x 12

Surface plate unnamed

Granite sink cutout 8.5 x 8

Step right angle 6 x 6

Cylindrical Square 6"

Surfcenter Brunswick Engineering Inc.

Manufactures Data

sheets

Mitutoyo https://www2.mitutoyo.co.jp/eng/support/service/parts_list/index.php

Techniques

Interference fits

0.2mm for a a 140mm bore? approximently 1/1000

Machining glass

- mount on machine wax

- carbide mill or drill

- RPM 1000-2000 RPM - for 4mm end mill or more? - Will wear

tool.

- Use cutting fluid to prevent fracture cooling.

- depth of cut - 200um

People

Phil Perry Hepler KS 66746 - restores machines.

Peter L Stanton - edge precision - Huston TX

Lance Baltzley - source of precision ground stones.

Chris Baca and Mikey Baca - Precision Instrument Repair 909 766

5041 or 760 561 2400

Email