Insert Shape 1st char

Insert Shape 1st charThis information HAS errors and is made available

WITHOUT ANY WARRANTY OF ANY KIND and without even the

implied warranty of MERCHANTABILITY or FITNESS FOR A

PARTICULAR PURPOSE. It is not permissible to be read by

anyone who has ever met a lawyer or attorney. Use is confined to

Engineers with more than 370 course hours of engineering.

If you see an error contact:

+1(785) 841 3089

inform@xtronics.com

We have two systems: the American National Standards Institute (ANSI) indexable-insert identification system and the International Organization of Standards (ISO) system. The ANSI system is confined mainly to the United States and is available as ANSI publication No. 212.4. Most of the rest of the world uses the ISO identification system, although it is used in the United States as well. Some European and Asian insert suppliers use ISO codes in their U.S. sales efforts, and U.S. tool exporters often code their products in ISO standard for overseas sales and distribution. This global distribution of inserts makes it important to understand both systems. Often - the same insert can be described by either system.

Inscribed Circle (IC) - is the largest circle that you could draw

within the shape of the insert.

The ANSI code tends to be found on older tools. Tool manufactures have added custom prefixes and suffixes to the standard code where needed.

ANSI code consists of up to 10 alphanumeric characters. Of these 10, the first seven are needed to identify. The first four of these seven characters are letters that give the shape of the insert. The next three numbers give the insert size.

Insert Shape 1st char

Insert Shape 1st charThe first character gives the insert shape. Letter codes for

simple shapes exist, such as round (R), triangular (T), and square

(S), diamonds (C, D, M, and V), octagons (O), pentagons (P), and

parallelograms (A, B, E, and F). Some manufacturers produce custom

l shapes for which they adopt their own code identification. Some

codes overlap and mean different things depending on the

manufacturer. (G might mean a 45° parallelogram or an uneven

hexagon)

T _ _ _ - _ _ _ - _ - _ _

Clearance Angle

2nd char

Clearance Angle

2nd charClearance angle of the insert, (the angle between the top of the tool and the flank) is specified as the angular difference from 90°. For example, the code letter N represents a 90° between top and flank, or 0° clearance. The letter P means a clearance angle of 11°. Common clearance angles range from 0° (N) to 30° (G).

T N _ _ - _ _ _ - _ - _ _

Tolerance ranges under which the insert is

manufactured. Often we find the letter G in this position. This

represents a tolerance of 0.001" on the tool’s inscribed circle

(IC) dimension, 0.001" on the tip-radius altitude, and 0.005" on

the tool thickness. The M code is found on nonground,

roughing-style tools where it means a tolerance of 0.002" to

0.010" on the tool’s IC and 0.005" on the tool thickness.

Tolerance ranges under which the insert is

manufactured. Often we find the letter G in this position. This

represents a tolerance of 0.001" on the tool’s inscribed circle

(IC) dimension, 0.001" on the tip-radius altitude, and 0.005" on

the tool thickness. The M code is found on nonground,

roughing-style tools where it means a tolerance of 0.002" to

0.010" on the tool’s IC and 0.005" on the tool thickness.

T N M _ - _ _ _ - _ - _ _

Here we find the design of the insert’s mounting system to

cutting-surface. The code N tells us we have a flat-top,

clamp-type insert. Add a center hole for screw mounting, and we

have code A.

This fourth character describes some 17 different tool features and there is the X designation for special designs. Strangely, this character is often omitted when describing commonly known turning or milling inserts.

T N M G - _ _ _ - _ - _ _

At this point, the code system changes from letters to numbers to describe the physical size of the insert.

The insert’s IC in 1/8" increments for inserts 1/4" and up.

A 1/4" IC insert is definded as '2', representing 2/8" and a for a

1/2" IC insert we find the number 4. BUT - if it is an insert with

IC dimensions under 1/4" the number represents the IC dimension

instead in 1/32" increments. Thus; the number 2 represents 2/32"

or 1/16".

T N M G - 4 _ _ - _ - _ _

For inserts with IC over 1/4" and greater, this number is the thickness in 1/16" increments. Smaller IC dimensions of less than 1/4" and this number is the thickness in 1/32" increments. Common triangular small tools often have a thickness of 3/32", and thus '3' is found in the sixth place.

T N M G - 4 3 _ - _ - _ _

The seventh character can be a number or a letter.

If a numbers is found here, we have a corner radii (normally turning tool). The corner radius is specified as the number of 1/64" increments. For example, a 1/32" radius is represented by the number 2, and a 3/64" radius by the number 3.

T N M G - 4 3 2 - _ - _ _

A letter in the seventh place specifies the type of corner chamfers of the tool. This letter gives us the handedness and angle of the corner chamfers, relative to the insert side For example, the letter E represents a 15° chamfer on a right-hand tool. The same 15° chamfer in left-hand configuration is the letter H. A tool with two 15° chamfers is the letter L. Best to reference a chart or even better the tool supplier’s documentation if you find a letter here.

S N K _ - 4 3 E - _ - _ _

The eighth character can be a letter or a number with two cases; For nonmilling inserts(number for 7th char), we find letters. An A, B, or C specifies honed edges, an N indicates negative lands, and a J identifies polished insert-rake surfaces.

T N M G - 4 3 2 - C - _ _

Milling insert tools (letter in 7th place) , have a number in the

eighth place which specifies the milling insert’s wiper flat

length and is measured in 1/32" increments. The wiper flat is most

often a chamfer and ultimately produces the surface finish on the

workpiece. Thus a 2 is 2/32 or 1/16" long wiper flat

S N K _ - 4 3 E - 2 - _ _

For nonmilling inserts, the ninth and tenth places are most often

used by tool producers to distinguish special features of their

products. But for milling inserts, the ninth character indicates

the direction of cut. This place is identified by the letter R for

right or L for left.

For both milling and turning tools, the tenth character is used at the insert producer’s option.

S N K _ - 4 3 E - 2 - R _

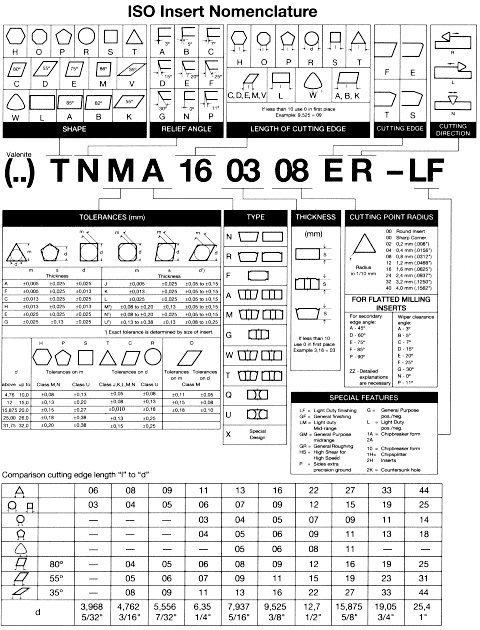

While the ISO insert description system uses metric units rather than inches, it has many of the features of the ANSI system. In particular, the first four characters are practically identical to the ANSI system. The first is the shape, the second is the clearance angle, the third is the tolerance range, and the fourth is the cutting-surface configuration and mounting system. A notable exception: In the ISO system, the fourth character is always used when describing milling inserts; in the ANSI system, it is often omitted.

T N M A - __ __ __ - __ - __

The big difference first shows itself in the fifth place. In the ISO system, the fifth place describes the insert size by specifying the tool’s side length to the closest millimeter. This place therefore requires two digits for a proper description. Tool sizes designated under this system will vary significantly from tool sizes under the ANSI system, as the following example illustrates.

In the ANSI system, a 1/2" IC insert is represented by the number 4 (4/8"), regardless of the tool’s shape. But because a tool’s shape affects its side length, its shape will also affect its size description. Under the ISO system, a 1/2" IC insert will be represented by the number 12 (12mm) if it is a round, square, or 80° diamond insert; 22 if it is triangular; or 15 if it is a 55° diamond tool.

T N M A - 16 __ __ - __ - __

The sixth place in the code is also different from the ANSI system. Like the fifth place, it requires two digits and describes the tool thickness rounded off to the lowest whole millimeter. For example, a 1/8" thick insert measures 3.18mm and has the code 03. A 3/16" thick insert measures 4.76mm and has the code 04.

T N M A - 16 03 __ - __ - __

As in the ANSI code, the seventh character in the ISO code can be a number or a letter. Numbers are used for tools having corner radii, or turning tools, and letters are used for milling tools. For turning tools, the seventh place represents the nose radius size on the insert. Once again, the ISO system uses a two-digit code in this place. The code represents the radius size in tenths of a millimeter. For example, a 1mm nose radius would have the code 10, whereas a 0.5mm radius would have the code 05.

T N M A - 16 03 08 - __ - __

For milling tools, the ISO system breaks the two letters in the seventh place into separate tool identifiers. The first letter identifies the angle of the wiper flat, or actual cutting edge, relative to the insert side, much like the ANSI code. The second letter describes the clearance angle of the wiper flat.

This tool geometry feature is not part of the ANSI system. In the example below, the letter A describes corner chamfers at 45° to the tool sides. The N following the A means the surface has a 0° or negative clearance angle.

T N L N - 12 04 AN - __ - __

As in the ANSI system, there are additional characters in the ISO system that can be employed but are often omitted. They are the cutting edge condition, the direction of feed, and the manufacturer’s optional area.

Superabrasive Inserts

Superabrasive inserts can be supplied in a wide variety of shapes and sizes. Three groups or categories can be established: full-topped indexable inserts, tipped indexable and single-edge inserts, and special-design tools such as rotating tools and saws.

Full-topped indexable inserts, tools with a superabrasive layer covering the entire top or top and bottom surfaces, can be identified adequately with the code systems just described. This is not so with tipped inserts, which have a substrate material that is formed into the familiar shapes described by ANSI or ISO codes. The actual cutting material, the superabrasive segment, is formed into an almost infinite variety of shapes and sizes and is inlaid into the base material.

On a tipped insert, the size of the superabrasive insert, or segment, is a variable. Depending on the end user’s planned DOC, he might utilize a very small or very large segment.

At this time, each superabrasive insert supplier has its own unique method of coding tipped inserts. Some are close to the ANSI or ISO standard, while others use codes that cannot be related to the insert standards. The tool suppliers that stay close to the ANSI standard often will add a suffix to the normally used seven-character identification code. This suffix is used to describe the superabrasive segment’s working edge length. In some instances, it also identifies the grade of the superabrasive material. For example, one supplier may use the suffixes 2F and 2G for diamond-tipped inserts and 4F and 4G for PCBN-tipped tools. Other suppliers may use two numbers to represent the length of the segment as measured down the insert side length. Still others may not list the side length at all, and thus only use the standard ANSI code as though the segment were not even on the tool.

A standard code system for tipped inserts is being reviewed by ANSI. The code combination is based on a suffix being added to the normal 10-character ANSI system. This suffix describes the details of the segment geometry. It is hoped that superabrasive tool producers will adopt the proposed suffix standard as they have adopted the existing code. It is certain that the indexable-insert code systems will continue to evolve. With new insert geometries and materials being developed, the need to have a standardized description will remain. To stay current, users should periodically review the insert identification information from their suppliers.

| Top Page | wiki Index |