Tapers and Chuck

keys page

Disclaimer

This information HAS errors and is made available

WITHOUT ANY WARRANTY OF ANY KIND and without even the

implied warranty of MERCHANTABILITY or FITNESS FOR A

PARTICULAR PURPOSE. It is not permissible to be read by

anyone who has ever met a lawyer or attorney. Use is confined to

Engineers with more than 370 course hours of engineering.

If you see an error contact:

+1(785) 841 3089

inform@xtronics.com

- Tapers and Chuck keys page

- Disclaimer

- Milling Machine Tapers

- Spindle Size Number

-

- Universal Kwik-Switch

- Kwik-Switch 200 part numbers

- Universal 5 digit numbers *

means have..

- Universal 6 digit numbers

- Briney Numbers

- SPI numbers

- Scully-Jones numbers

- Tool-Holders with Collars or Flanges

- Single Flange Tool-Holders

- Dual Flange Tool-Holders

- BT-Flange and ISO-Flange

- Caterpillar V-flanges

- DIN 69871-A TAPER

- R8, R-8 or M1TR taper -- Common

Bridgeport Tapered Draw-Bar

- Machine Taper Dimensions table -

Morse - Brown & Sharp - Jarno - Jacobs

- Chuck keys

- B-Taper (DIN ISO 239)

- ER Tapers

- Taper wipers

Milling Machine

Tapers

Parent page is Machining

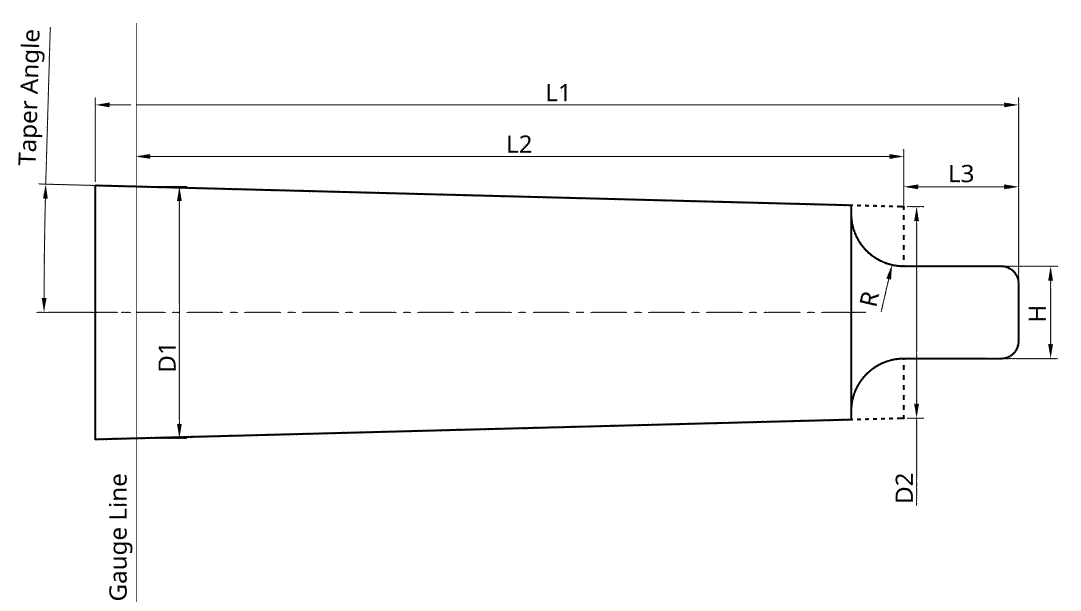

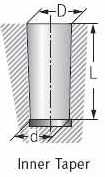

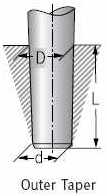

There are really only a few tapers in common use even with all

the names for milling machine tapers. Quite a few manual milling

machines use the "R-8" taper, but most CNC and large machines use

something else. A tool-holder consists of 2 sections separated by

the gage line (the gage line is an imaginary line marking the

portion of the tool-holder that matches the bottom edge of the

machine spindle). The taper fits into the spindle allowing the

machine spindle to transfer rotary motion to the tool holder which

holds the tool.

A toolholder has a 2 part specification, taper and tool. This

page covers the machine-to-toolholder standard and not the

holder-to-tool standard. and example might help. A NMTB #30 collet

chuck and an NMTB 1/2" endmill holder fit the same machine, but

hold different tools.

The NMTB refers to the taper standard family - the #30

the shank size (if they leave off the #30 part it is assumed to be

the small one.) At the end of the tool-holder name is the name of

the tool type - 1/2" end-mill holder

NMTB(National Tool Builders Association)

MMT stands for Milling Machine Taper - what became Erickson

quick-change spindles

Conversely, a NMTB 1/2" end-mill tool-holder and a Universal

Kwik-Switch 200 1/2" end-mill tool-holder will hold the same tool,

but fit different machines. The drawings below show only the taper

portion of the tool-holder.

Spindle Size

Number

The ANSI standard size is determined by the machine size; Larger

machines use larger shanks.

| Spindle size to Machine size |

| Taper Shank No. |

Machine Size |

| #60 |

Very large machines |

| #50 |

Medium size machines (20 to 50 HPs) |

| #40 |

Small size machines |

| #30 |

Very small machines |

All of the major tapers, except the Universal Kwik-Switch family,

use the 3 1/2" in 12" model of the NMTB or 7:24. A 3/8" end-mill

#50 NMTB tool-holder is about a serious 9 pounds of metal compared

to dainty 3/4 of a pound for a #30 NMTB 1/4" end-mill tool-holder.

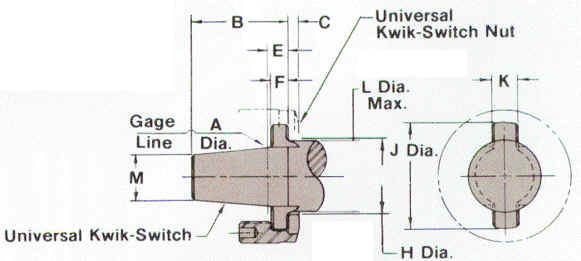

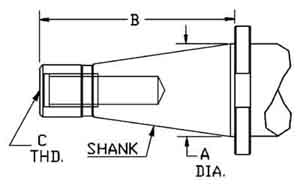

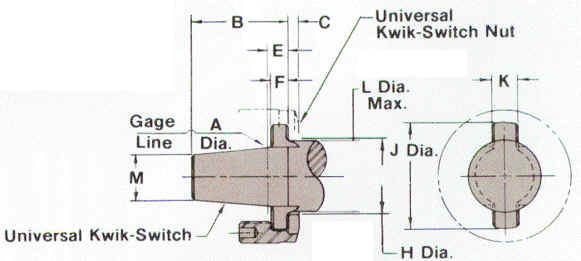

Universal

Kwik-Switch

A Tool-Holders with Ears!

|

This taper style is also made by Collis who call it

Rapid-Switch.

The Kwik-Switch is supplied as alternative tooling in

Bridgeport, Wells index, and other machines. The 200

series is pretty much equivalent to the NMTB #30, but has

more mass and a more positive lock.

This is not a Milling Machine taper.it is actually a 2

inch TPF.

2"/ft is about 9.46 deg But the taper on the

200 is really 9.142848 deg ..

the 7/24 tapers are 16.26 deg .. (The narrower Kwik-Switch

taper doesn't need as much vertical holding force - thus a

nut rather than a drawbar.. )

|

,

| Kwik-Switch Size |

A |

B |

C |

E |

F |

H |

J |

K |

L |

M |

| 100 |

.875 |

1.44 |

0.16 |

0.312 |

0.250 |

1.12 |

1.56 |

0.375 |

1.06 |

0.68 |

| 200 |

1.312 |

2.50 |

0.22 |

0.375 |

0.312 |

1.75 |

2.12 |

0.500 |

1.68 |

0.97 |

200 in mm

|

33.3248

|

63.500

|

5.588

|

9.525

|

7.9248

|

44.450

|

53.848

|

12.700

|

42.672

|

24.638

|

| 300 |

1.625 |

2.94 |

0.28 |

0.438 |

0.375 |

2.00 |

2.50 |

0.500 |

1.94 |

1.22 |

| 400 |

2.250 |

3.62 |

0.34 |

0.500 |

0.438 |

2.81 |

3.25 |

0.625 |

2.75 |

1.75 |

|

According to Wells Index:

200 KS stands for 200 Kwik Switch (AKA Rapid-Switch or rapid

change) designed by Universal Engineering and it is not like

any other. It is about the same size as #30 NMTB or #30 MMT.

Used and new tooling is available.

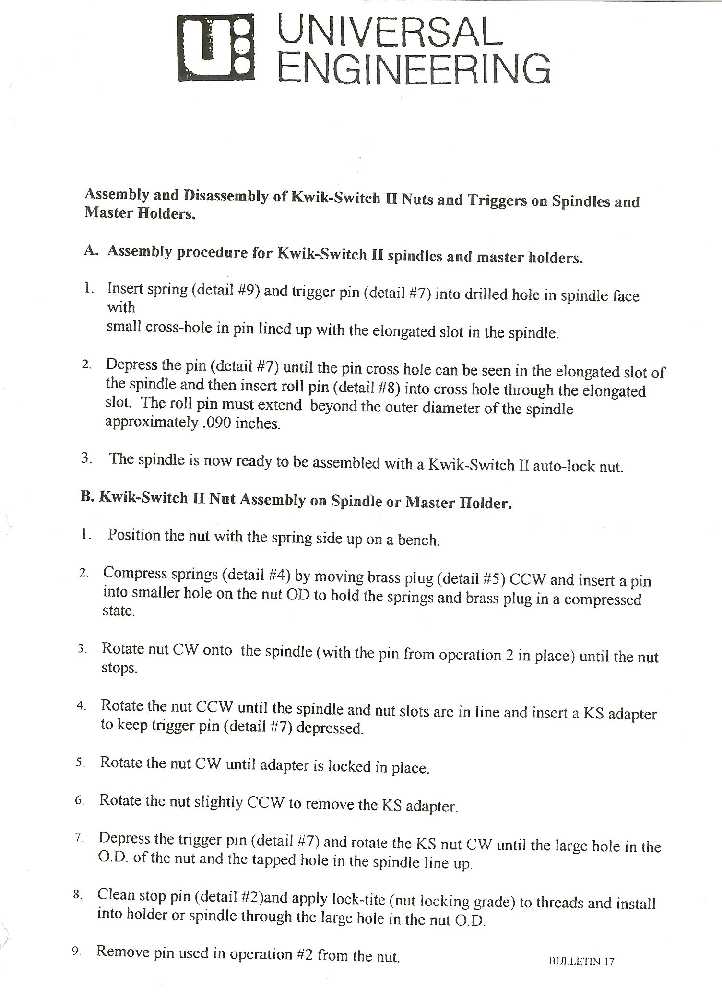

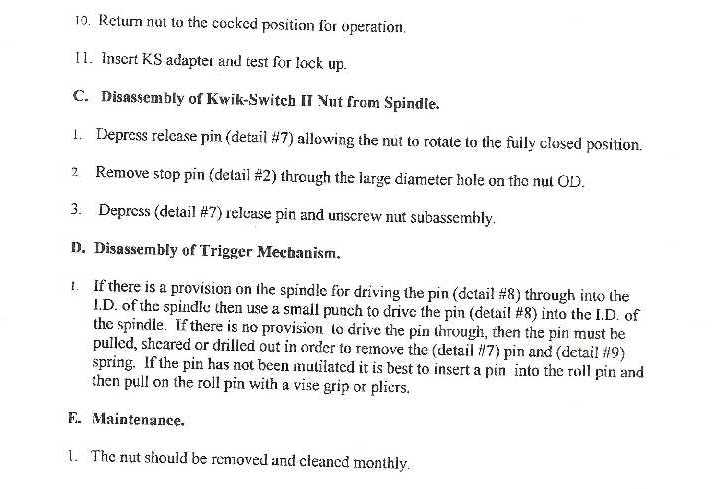

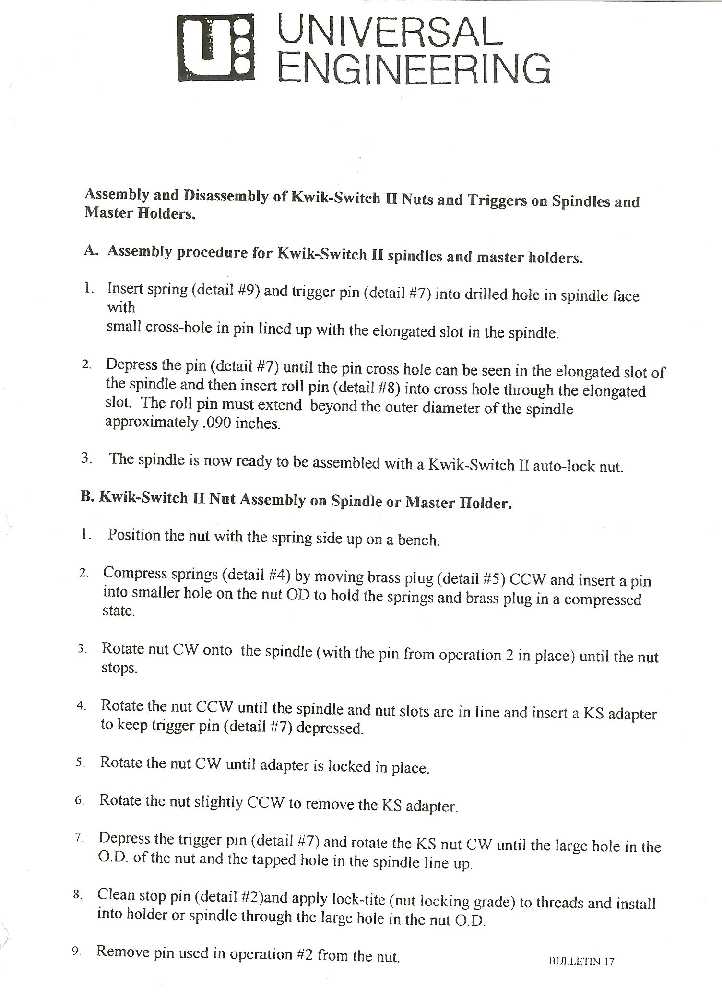

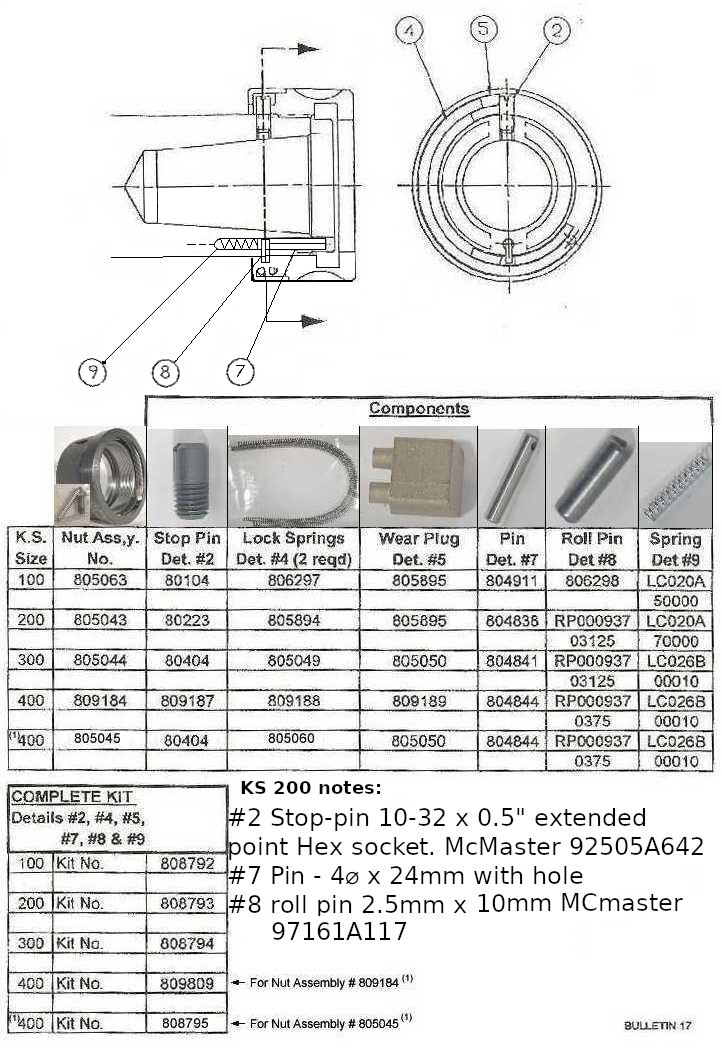

As the holder lock-nut is opened, coil springs are compressed. When

the open position is reached, a mechanical latch holds the nut open.

This latch is operated by a trigger pin. The trigger pin is

depressed by one of the tool adapters lugs as the adapter is

inserted into the spindle socket. When the trigger pin is depressed,

it releases the compression springs. This causes the spindle nut to

rotate which draws the tool adapter up into the locking angle

tapered socket. Since locking force is always present, the nut

continues to tighten under load.

Other companies make tooling that will fit it and call it rapid

switch or rapid change. It is about the same size as #30 NMTB or #30

MMT. Used and new tooling is available

http://universaldevlieg.com/

https://toolholderexchange.com/kwik-switch/

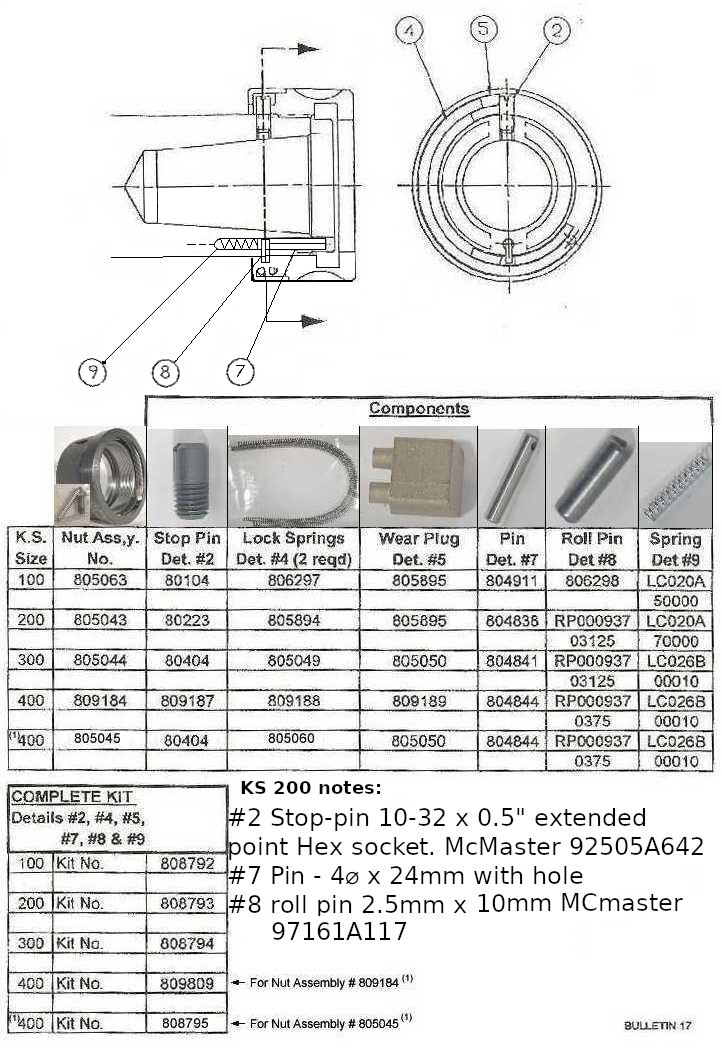

VERY IMPORTANT - one needs to press in the trigger-pin #7 while

disassembling below to prevent damage to roll-pin.

In part B below - one wants to compress the spring most of the way

so there is something to stop the roll-pin as it is inserted.

2008 Catalog

Kwik-Switch 200

part numbers

Universal 5 digit

numbers * means have..

*15905 Acura-Tap T&C Collet Chuck 1/2"

15925 Quick Change Tension & Compression Tap Chucks - tap

adapter size -1 BILZ WE 1 3/8

Tap holders https://www.bilzusa.com/parts_info.php?tool=tapping_WE_adapter_WE_ANSI

#0-9/16 Hand 1/8 Pipe

More tap adapters - see catalog above

15707 200 Tap Chuck

60047 Jacobs Taper #33 Adapter (same as 80255)

80220 1/2" DT collet Chuck

80226 Morse #1

*80227 Morse #2

80228 Morse #3 has open end drift

Shell mill adapters are American National Standard mount..

80219 ww

80220 Y double taper collet holder - uses 551084 collet nut

80221 Z double taper collet holder - uses 551090 collet nut

80222 ZZ

80231 Shell mill adapter 0.500"

80232 Shell mill adapter 0.750"

*80233 Shell mill adapter 1.000" (Pilot Diameter 1.000 - Pilot

Length .68(11/16) - Nose Diameter 2.12 - Drive Key Size 3/8)

80235 1/16 -3/8" Acura-Flex Collet Chuck

80236 7/64 -1/2" Acura-Flex Collet Chuck

80237 7/64 - 3/4" Acura-Flex Collet Chuck

* 80239 Locking Fixture - holds tool holder for tightening

*80242 End Mill Holder 0.375" and as Briney

**80243 End Mill Holder 0.500" and as Briney (total 3)

80244 End Mill Holder 0.625" as Briney

*80245 End Mill Holder 0.750" and as Briney

*80246 End Mill Holder 0.875"

*80247 End Mill Holder 1.000"

Jacobs Adapters - more lower

80250 Master Morse taper #3 -

want - no longer made

80251 Jacobs #0

80252 Jacobs #1 As Scully-Jones 95512-J1

*80253 Jacobs # 2

80254 Jacobs #6

*80255 Jacobs #33

80257 Morse 4 master head

80261 Stubarbor 3/4" 0.75

80262 Stub arbor 7/8" 0.875

*80263 1" Stub Arbor With 4 spacers (two 1/4", one 3/8", and one

1/8"), removable Woodruff key and nut

80274 Boring Head (for 3/8" sq tool)

80275 Boring Head (for 3/8" sq tool) 6.5" long

*80292 Acme Shank Adapter 3/4"

80698 Jacobs #3

*80721 End-mill holder .250"

80757 BORING HEAD ADAPTER 1-1/4"-20?? 1 1/4 fine thread 1/2 long and

3 3/8 OAL over all length

80851 1.5" mill holder

80881 Boring Head Adapter 7/8-20

80891 Boring Head Adapter 1.5-18,

90258 Jacobs # 2 ???

* 97041 = 97101 + 97047

*97047 (head) OY boring Chuck head - Y Double taper

*97101 Shank (could be about the same as 80891?? 7/8-20 thread

mount.

97374 (head) 97375(whole assembly) 97101 (shank)

97375 3 hole (3/8") boring Chuck.

Universal 6 digit

numbers

801163 Jacobs #4

801431 End Mill Holder 0.1875"

801512 Boring Head Adapter 7/8-18

802481 End Mill Holder 0.3125"

802785 End Mill Holder 0.125"

*805560 Boring tool Valenite E-Z-set AHACS (1.25"??) 55°

(little one) These must use triangle inserts..

* 805564 Boring tool size 5 MicroBore, 5" projection Has

317896? microbore cartridge (5-40x0.375" FH cartrige scresw"

#3-48x.250" insert screw) 55°

Insert - TC_ _1102_ _ ???? Valenite E-Z-set BHACS (B-Ang

-- approach 85°

809562 arbor 7/8" recess with 1/2-20 bolt

ER collet chucks

*KS2ER16112 ER16 - max tightening torque 68 Nm

*KS2ER32181 ER32 - max tightening torque 170 Nm

Dimensions of

Kwik-Switch 200 mill holders

|

| Number |

A(diameter) |

B |

C |

M |

| 802785 |

0.125 |

0.44 |

1.03 |

0.62 |

| 801431 |

0.1875 |

0.56 |

1.03 |

0.68 |

| 80721 |

0.25 |

0.75 |

1.41 |

1 |

| 802481 |

0.3125 |

0.75 |

1.41 |

1 |

| 80242 |

0.375 |

0.75 |

1.41 |

1 |

| 802482 |

0.4375 |

? |

? |

? |

| 80243 |

0.5 |

0.88 |

1.41 |

1.31 |

| 80244 |

0.625 |

0.94 |

1.41 |

1.62 |

| 80245 |

0.75 |

1 |

1.66 |

1.72 |

| 80246 |

.8750 (1) |

1 |

1.91 |

1.94 |

| 80247 |

1.0000 (1) |

1.12 |

2.03 |

1.94 |

Universal Engineering (TSD) part numbers, Master holders

-dimensions and specifications

Kwik

Switch

Family |

N.M.M.

Shank |

Universal

Part No. |

C |

D |

Thread |

Nut

Part No. |

Wrench

Part No. |

| 100 |

30 |

80108 |

1.75 |

2.00 |

1/2-13 |

805063 (A) |

80103 |

| 100 |

30 |

80105 |

1.55 |

2.00 |

1/2-13 |

80102 (M) |

80103 |

| 100 |

40 |

80115 |

1.75 |

2.00 |

5/8-11 |

805063 (A) |

80103 |

| 100 |

40 |

80106 |

1.5 |

2.00 |

5/8-11 |

80102 (M) |

80103 |

| 200 |

30 |

80225 |

3.28 |

2.56 |

1/2-13 |

805043 (A) |

80203 |

| 200 |

30 |

80204 |

3.28 |

2.56 |

1/2-13 |

80202 (M) |

80203 |

| 200 |

40 |

80238 |

2.00 |

2.56 |

5/8-11 |

805043 (A) |

80203 |

| 200 |

40 |

80205 |

1.719 |

2.56 |

5/8-11 |

80202 (M) |

80203 |

| 200 |

50 |

80248 |

2.06 |

2.56 |

1-8 |

805043 (A) |

80203 |

| 200 |

50 |

80206 |

1.84 |

2.56 |

1-8 |

80202 (M) |

80203 |

200

|

B&S #9

|

2059

|

3.33

|

2.56

|

1/2-13

|

80202

(M) |

80203

|

| 300 |

40 |

804446 |

2.91 |

3.00 |

5/8-11 |

805044 (A) |

80303 |

| 300 |

40 |

80305 |

2.91 |

3.00 |

5/8-11 |

80302 (M) |

80303 |

| 300 |

50 |

804448 |

2.25 |

3.00 |

1-8 |

805044 (A) |

80303 |

| 300 |

50 |

80306 |

2.03 |

3.00 |

1-8 |

80302 (M) |

80303 |

| 400 |

50 |

804495 |

2.78 |

3.75 |

1-8 |

805045 (A) |

80403 |

| 400 |

50 |

80406 |

2.72 |

3.75 |

1-8 |

80402 (M) |

80403 |

(M) Manual Nut (A)

Automatic Nut (NMM ) National Milling Machine

Briney Numbers

*QS200E-038-141 3/8" end mill holder

*QS200E-050-141 1/2" end mill holder

*QS200E-062-141 5/8" end mill holder

*QS200E-075-166 3/4" end mill holder

*QS200-THM-100 Tap Holder ? Not as heavy as the end-mill

holder

SPI numbers

The end dash-number is not always there

74-025 -8 thru 74-27 -4 double angle collets

End-mill holders

74-032 -4 3/16"

74-033 -2 1/4"

74-034 -0 5/16"

* 74-035 -7 3/8"

74-036 -5 1/2"

74-037 -3 5/8"

74-038 -1 3/4"

74-039 -9 7/8"

*74-040 -7 1" end-mill holder

Shell End mill arbors

74-096 -9 3/4" spigot

74-097 -7 1"

74-083 -7 Jacobs 1

74-093 -6 Jacobs 2

74-084 -5 jacobs 3

74-085 -2 Jacobs 6

*74-086 -0 B16 Jacobs 33

74-062 -1 MT1

74-063 -9 MT2

74-064 -7 MT3

74-108 -2 Tapping head tap holder #4-1/2

Scully-Jones

numbers

*95512-J1 - Jacobs #1

Tool-Holders with

Collars or Flanges

Single Flange

Tool-Holders

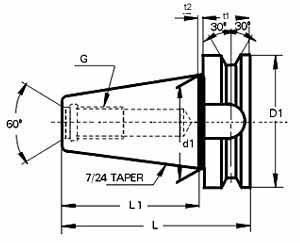

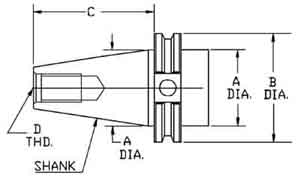

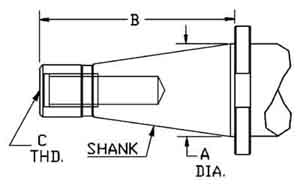

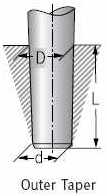

| The single collar taper is the most popular, as evidenced

by the numerous names it has. Most often NMTB or Erickson

Quick Change. NMTB (from National MachineTool

Builders' Association, 1927. and also known as DIN

2080 / IS 2340 SHANK)

You'll see it called Quick Change, NMTB, MM, National

Standard, American Standard Machine Taper, ISOXX, &

QCXX...

The American Standard Steep Machine Taper (ASA

B5.10-1963) defines 12 tapers: #5, #10, #15, #20, #25,

#30, #35, #40, #45, #50, #55, #60. Those numbers in bold

are the "Preferred Series" while the others are in the

"Intermediate Series".

ANSI mentions six taper shank sizes including #30, #35,

#40, #45, #50, and #60. For all the sizes the taper is 3

1/2" per foot. The taper is 3.500 inches per foot and

is also referred to as "7 in 24" or 7/24 or better yet

7:34; the computed angle is 16.5943 degrees

|

,  |

| Shank |

Slot |

A |

B |

C |

| 30 |

16.1 [.634] |

31.75 [1.250] |

68.4 [2.75] |

1/2-13 |

| 40 |

16.1 [.634] |

44.45 [1.750] |

93.4 [3.75] |

5/8-11 |

| 50 |

25.7 [1.012] |

69.85 [2.750] |

126.8 [5.12] |

1-8 |

|

Dual Flange

Tool-Holders

There are two common dual flange types: V-flange (often referred

to as Caterpillar V-flanges) and BT-flange.

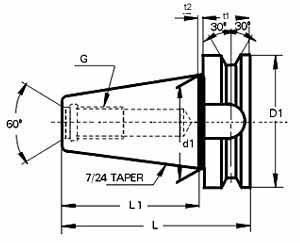

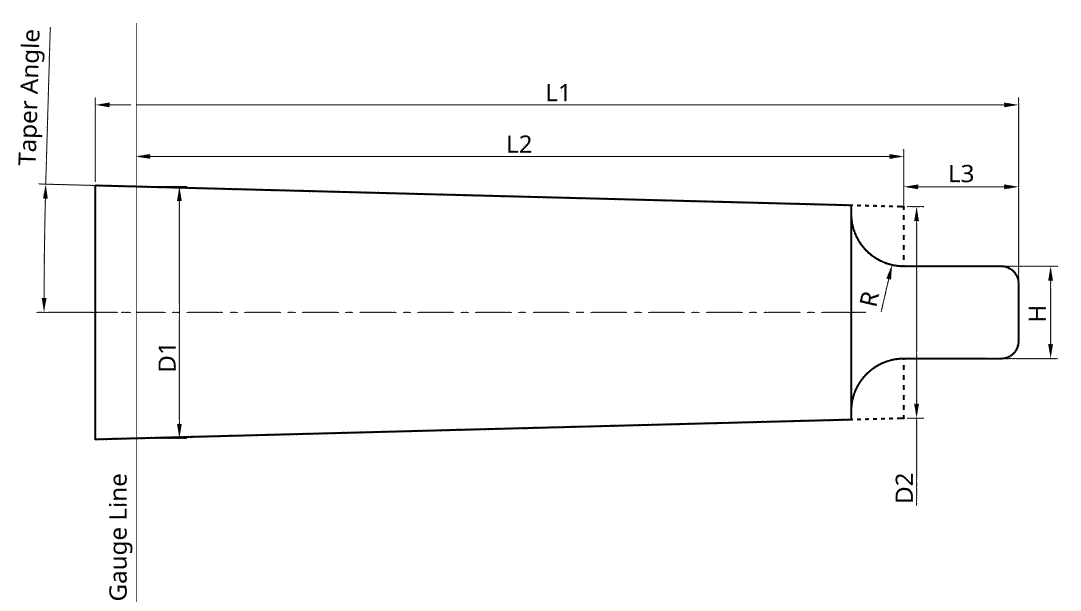

BT-Flange and

ISO-Flange

| BT-flange holders are widely used in Japanese and European

made machining centers and have metric threads for the

retention knob, but their adapters can be designed to

accommodate a wide range of inch-dimensioned cutting tools.

The BT Flange is also known as

- JMTBA MAS-403 "BT"

- JIS B 6339 - 1986

- JIS B6339 - 1992

- ISO 7388/1 - 1983

|

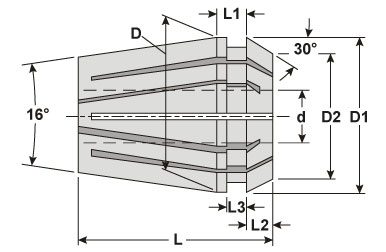

,

| MODEL |

D1 |

D2 |

t1 |

t2 |

L1 |

L2 |

L3 |

L |

d1 |

d2 |

G |

| BT20* |

? |

? |

? |

? |

? |

? |

? |

? |

? |

? |

? |

| BT30 |

46 |

38 |

20 |

2 |

48.4 |

34 |

24 |

70.4 |

31.75 |

12.5 |

M12 |

| BT40 |

63 |

53 |

25 |

2 |

65.4 |

70 |

30 |

92.4 |

44.45 |

17 |

M16 |

| BT50 |

100 |

85 |

35 |

3 |

101.8 |

90 |

45 |

139.8 |

69.85 |

25 |

M24 |

*used by SAKAI MM-250 S3 Milling machine |

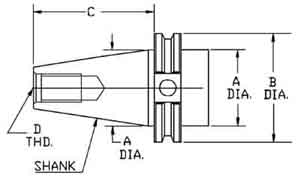

Caterpillar

V-flanges

| Caterpillar V-flanges use inch threads for the retention

knob and are used to hold inch-dimensioned cutting tools.

You'll see the CAT flange referred to as DIN69871

I've seen them most often referred to as CAT-30, CAT-40,

CAT-45, and CAT-50 and CAT-40 seems to be the most common.

|

,

SHANK

SIZE |

A

GAGE LINE |

B |

C |

D |

| V30 |

1.250 |

1.812 |

1.875 |

1/2-13 |

| V40 |

1.750 |

2.500 |

2.687 |

5/8-11 |

| V45 |

2.250 |

3.250 |

3.250 |

3/4-10 |

| V50 |

2.750 |

3.875 |

4.000 |

1-8 |

[Inches]

|

DIN 69871-A TAPER

| Need information on this one... |

,

| MODEL |

D1 |

D2 |

t1 |

t2 |

L1 |

L2 |

L3 |

d1 |

d2 |

M max |

G |

| 10 |

23 |

18.46 |

5.5 |

? |

20.5 |

? |

? |

15.875 |

? |

? |

? |

| 20 |

33 |

27 |

8 |

? |

33.3 |

? |

? |

22.225 |

? |

? |

? |

| 25 |

37 |

31 |

8 |

? |

39.7 |

? |

? |

25.4 |

? |

? |

? |

| 30 |

50 |

44.30 |

15.9 |

3.2 |

47.8 |

33.5 |

24 |

31.75 |

13 |

45 |

M12 |

| 40 |

63.55 |

56.25 |

15.9 |

3.2 |

68.4 |

42.5 |

32 |

44.45 |

17 |

50 |

M16 |

| 50 |

97.5 |

91.25 |

15.9 |

3.2 |

101.75 |

61.5 |

47 |

69.85 |

25 |

80 |

M24 |

|

R8, R-8 or M1TR

taper -- Common Bridgeport Tapered Draw-Bar

|

This is not truly a taper as defined by Machinery's

Handbook, since it is held in place by a drawbar. Picture

a long 7/16"NF bolt leading down through the spindle,

threading onto the R-8 tool-holder. The included angle is

8.25°1 OD of 1.25" 18.85/2 degrees or 8.25??

Taper = 16 Deg 51 Min.Included

End Dia. .9495 +0 -.0003

Overall from front dia. of 1 1/4"is 4" Undercut dia.

15/16"

The "arctan(3.5/12)" solution by definition implies a

right triangle with a 3.5" short side and 12" long side.

Thus, the hypotenuse is 1.25".

|

,  |

Machine Taper

Dimensions table - Morse - Brown & Sharp - Jarno - Jacobs

| Taper Name |

Large End

Diameter |

Taper/ft |

Taper/in |

Angle in degrees

From Center |

Small End

Diameter |

Length |

| #0 Morse |

0.356 |

0.625 |

0.052 |

1.491 |

0.252 |

2.000 |

| #1 Morse |

0.475 |

0.599 |

0.050 |

1.429 |

0.369 |

2.130 |

| #2 Morse |

0.700 |

0.599 |

0.050 |

1.431 |

0.572 |

2.560 |

| #3 Morse |

0.938 |

0.602 |

0.050 |

1.438 |

0.778 |

3.190 |

| #4 Morse |

1.231 |

0.623 |

0.052 |

1.488 |

1.020 |

4.060 |

| #4-1/2 Morse |

1.500 |

0.624 |

0.052 |

1.489 |

1.266 |

4.500 |

| #5 Morse |

1.748 |

0.632 |

0.053 |

1.507 |

1.475 |

5.190 |

| #6 Morse |

2.494 |

0.626 |

0.052 |

1.493 |

2.116 |

7.250 |

| #7 Morse |

3.270 |

0.624 |

0.052 |

1.489 |

2.750 |

10.000 |

| #1 Brown & Sharpe |

0.239 |

0.502 |

0.042 |

1.198 |

0.200 |

0.940 |

| #2 Brown & Sharpe |

0.300 |

0.502 |

0.042 |

1.198 |

0.250 |

1.190 |

| #3 Brown & Sharpe |

0.375 |

0.502 |

0.042 |

1.198 |

0.313 |

1.500 |

| #4 Brown & Sharpe |

0.421 |

0.502 |

0.042 |

1.199 |

0.350 |

1.690 |

| #5 Brown & Sharpe |

0.539 |

0.502 |

0.042 |

1.197 |

0.450 |

2.130 |

| #6 Brown & Sharpe |

0.600 |

0.503 |

0.042 |

1.201 |

0.500 |

2.380 |

| #7 Brown & Sharpe |

0.720 |

0.502 |

0.042 |

1.197 |

0.600 |

2.880 |

| #8 Brown & Sharpe |

0.899 |

0.501 |

0.042 |

1.196 |

0.750 |

3.560 |

| #9 Brown & Sharpe |

1.078 |

0.501 |

0.042 |

1.196 |

0.900 |

4.250 |

| #10 Brown & Sharpe |

1.260 |

0.516 |

0.043 |

1.232 |

1.045 |

5.000 |

| #11 Brown & Sharpe |

1.498 |

0.501 |

0.042 |

1.196 |

1.250 |

5.940 |

| #12 Brown & Sharpe |

1.797 |

0.500 |

0.042 |

1.193 |

1.500 |

7.130 |

| #13 Brown & Sharpe |

2.073 |

0.500 |

0.042 |

1.194 |

1.750 |

7.750 |

| #14 Brown & Sharpe |

2.344 |

0.500 |

0.042 |

1.194 |

2.000 |

8.250 |

| #15 Brown & Sharpe |

2.615 |

0.500 |

0.042 |

1.194 |

2.250 |

8.750 |

| #16 Brown & Sharpe |

2.885 |

0.500 |

0.042 |

1.194 |

2.500 |

9.250 |

| #17 Brown & Sharpe |

3.156 |

0.500 |

0.042 |

1.194 |

2.750 |

9.750 |

| #18 Brown & Sharpe |

3.427 |

0.500 |

0.042 |

1.194 |

3.000 |

10.250 |

| #2 Jarno |

0.250 |

0.600 |

0.050 |

1.432 |

0.200 |

1.000 |

| #3 Jarno |

0.375 |

0.600 |

0.050 |

1.432 |

0.300 |

1.500 |

| #4 Jarno |

0.500 |

0.600 |

0.050 |

1.432 |

0.400 |

2.000 |

| #5 Jarno |

0.625 |

0.600 |

0.050 |

1.432 |

0.500 |

2.500 |

| #6 Jarno |

0.750 |

0.600 |

0.050 |

1.432 |

0.600 |

3.000 |

| #7 Jarno |

0.875 |

0.600 |

0.050 |

1.432 |

0.700 |

3.500 |

| #8 Jarno |

1.000 |

0.600 |

0.050 |

1.432 |

0.800 |

4.000 |

| #9 Jarno |

1.125 |

0.600 |

0.050 |

1.432 |

0.900 |

4.500 |

| #10 Jarno |

1.250 |

0.600 |

0.050 |

1.432 |

1.000 |

5.000 |

| #11 Jarno |

1.375 |

0.600 |

0.050 |

1.432 |

1.100 |

5.500 |

| #12 Jarno |

1.500 |

0.600 |

0.050 |

1.432 |

1.200 |

6.000 |

| #13 Jarno |

1.625 |

0.600 |

0.050 |

1.432 |

1.300 |

6.500 |

| #14 Jarno |

1.750 |

0.600 |

0.050 |

1.432 |

1.400 |

7.000 |

| #15 Jarno |

1.875 |

0.600 |

0.050 |

1.432 |

1.500 |

7.500 |

| #16 Jarno |

2.000 |

0.600 |

0.050 |

1.432 |

1.600 |

8.000 |

| #17 Jarno |

2.125 |

0.600 |

0.050 |

1.432 |

1.700 |

8.500 |

| #18 Jarno |

2.250 |

0.600 |

0.050 |

1.432 |

1.800 |

9.000 |

| #19 Jarno |

2.375 |

0.600 |

0.050 |

1.432 |

1.900 |

9.500 |

| #20 Jarno |

2.500 |

0.600 |

0.050 |

1.432 |

2.000 |

10.000 |

| #0 Jacobs |

0.250 |

0.592 |

0.049 |

1.412 |

0.228 |

0.440 |

| #1 Jacobs |

0.384 |

0.925 |

0.077 |

2.207 |

0.333 |

0.660 |

| #2 Jacobs |

0.559 |

0.979 |

0.082 |

2.335 |

0.488 |

0.880 |

| #2 Short Jacobs |

0.549 |

0.979 |

0.082 |

2.335 |

0.488 |

0.750 |

| #3 Jacobs |

0.811 |

0.639 |

0.053 |

1.525 |

0.746 |

1.220 |

| #4 Jacobs |

1.124 |

0.629 |

0.052 |

1.501 |

1.037 |

1.660 |

| #5 Jacobs |

1.413 |

0.620 |

0.052 |

1.480 |

1.316 |

1.880 |

| #6 Jacobs |

0.676 |

0.623 |

0.052 |

1.487 |

0.624 |

1.000 |

| #33 Jacobs |

0.624 |

0.762 |

0.064 |

1.818 |

0.561 |

1.000 |

#33 Jacobs mm

|

15.8496

|

|

|

1.818 |

13.2494

|

25.4

|

| Taper Name |

Large End

Diameter |

Taper/ft |

Taper/in |

Angle in degrees

From Center |

Small End

Diameter |

Length |

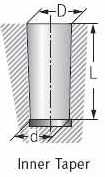

Morse in metric

| MT Size |

D1 (mm) |

D2 (mm) |

L2 (mm) |

Taper (μm/mm) |

Half-Angle |

L1 (mm) |

L3 (mm) |

H (mm) |

R (mm) |

| 0 |

9.045 |

6.401 |

50.8 |

52.051 |

1°29'26" |

59.531 |

6.350 |

3.967 |

4 |

| 1 |

12.065 |

9.373 |

53.975 |

49.882 |

1°25'43" |

65.087 |

9.525 |

5.159 |

5 |

| 2 |

17.780 |

14.529 |

65.087 |

49.951 |

1°25'49" |

79.375 |

11.112 |

6.350 |

6 |

| 3 |

23.825 |

19.761 |

80.962 |

50.196 |

1°26'16" |

98.425 |

14.287 |

7.938 |

7 |

| 4 |

31.267 |

25.908 |

103.188 |

51.938 |

1°29'15" |

123.825 |

15.875 |

12.159 |

8 |

| 4.5 |

38.100 |

32.156 |

114.300 |

51.999 |

1°29'22" |

N/A |

N/A |

N/A |

N/A |

| 5 |

44.399 |

37.465 |

131.762 |

52.626 |

1°30'26" |

155.575 |

19.050 |

15.875 |

10 |

| 6 |

63.348 |

53.746 |

184.150 |

52.138 |

1°29'36" |

217.487 |

28.575 |

19.050 |

13 |

| 7 |

83.058 |

69.850 |

254.0 |

51.999 |

1°29'22" |

141.275 |

34.925 |

28.575 |

|

Note that Morse Taper sizes (e.g. MT2 or 2MT) are also sometimes

referred to by their German name Morse

Kegel (e.g. MK2). The dimensions for the same number Morse Taper

or Kegel are identical.

Parent page is Machining

Chuck keys

Need information about origin of standard and metric standards..

| Key |

Size |

Comments - Chucks |

| K0 |

1/8" 0.125" |

|

| K2 |

1/4" 0.250" |

|

| K3 (K3C?) |

5/16" 0.312 5" |

|

| K4 |

3/8 0.375" |

(#9) |

| K5 |

7/16 0.437 5" |

(#26) |

| K7 |

7/32" 0.218 75" |

|

| ?? |

21/64 0.328 125 |

|

| K30 |

15/64" 0.234 375 |

|

| K32 |

1/4" 0.250" |

|

| KG |

1/4" 0.250" |

|

| KI |

5/32" 0.156 25" |

|

| KK |

9/32" 0.281 25" |

|

| K30 |

15/64" 0.234 375" |

(#13) |

B-Taper (DIN ISO

239)

Often used for drill chucks, like the older Jacobs tapers - (B6

is very close to the end of a Morse taper II)

| Size |

Large

End |

Small

End Dia. |

Taper

Length |

Taper

per ft.** |

| B6 |

6,350mm

0.2500" |

5,85mm

0.2303" |

10mm

0.3937" |

0.6 |

| B10 |

10.094mm

0.3974" |

9,4mm

0.3701" |

14,5mm

0.5709" |

0.5743 |

| B12 |

12,065mm

0.4750" |

11,1mm

0.4370" |

18,5mm

0.7283" |

0.6259 |

| B16 |

15,733mm

0.6194" |

14,5mm

0.5709" |

24mm

0.9449" |

0.6165 |

| B18 |

17,780mm

0.7000" |

16,2mm

0.6378" |

32mm

1.2598" |

0.5925 |

| B18* |

17,431mm

0.6863" |

16,2mm

0.6378" |

25mm

0.9843" |

0.5909 |

| B22 |

21,793mm

0.8580" |

19,8mm

0.7795" |

40,5mm

1.5946" |

0.5905 |

| B24 |

23,825mm

0.9380" |

21,3mm

0.8386" |

50,5mm

1.9882" |

0.6 |

* 7mm short of DIN ISO 239

** 12((D-d)/L)

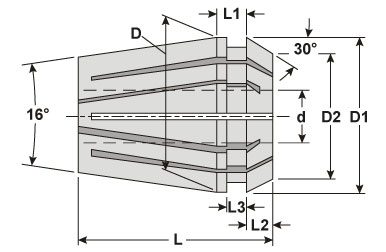

ER

Tapers

| ER Collet Size |

d H7 Capacity [mm] |

D |

D1 |

D2 |

L |

L1 |

L2 |

L3 |

| ER11 |

1.0 ~ 7.0 |

11 |

11.5 |

9.5 |

18 |

3.8 |

2.5 |

2 |

| ER16 |

1.0 ~ 10.0 |

16 |

17 |

13.8 |

27.5 |

6.26 |

4 |

2.7 |

| ER20 |

1.0 ~ 13.0 |

20 |

21 |

17.4 |

31.5 |

6.36 |

4.8 |

2.8 |

| ER25 |

1.0 ~ 16.0 |

25 |

26 |

22 |

34 |

6.66 |

5 |

3.1 |

| ER32 |

2.0 ~ 20.0 |

32 |

33 |

29.2 |

40 |

7.16 |

5.5 |

3.6 |

| ER40 |

3.0 ~ 26.0 |

40 |

41 |

36.2 |

46 |

7.66 |

7 |

4.1 |

Taper wipers

Taper wipers are used to get the last bit of grit off the metal -

a single spec can ruin the run out of the mechanical joint.

Traditionally, these have had felt wipers, but felt picks up the

dirt and holds it - mixed with oil you now have a crude lapping

compound.

A much better approach is to use a clean shop rag - or paper

towel - wrap around the taper cleaner and clean until no more dirt

comes out.

Email