-

- Disclaimer

- LinuxCNC

- Installing under buster - for

mesa

- Linux Command line

- LinuxCNC acronyms,

abbreviations, special terms, file-types

- Special terms

- File-types

- Create Ethernet connection to

Mesa card (this example used i793)

- testing:

- Change IP to non LAN network

- Write bit file to mesa card

- mesaflash syntax:

- Mesa config wizard

- Connection to 7i84D vis 7i44

- 7i29 notes

- Encoder notes

- INI file notes

- hal file notes

- Nomenclature

- Syntax

- Components

- iocontrol and halui (they

seem to have overlapping functions)

- estop pins

- Machine on-off

- Motion - accepts NML motion

commands, interacts with HAL in realtime

- wj200_vfd

- limit2 component

- PID loop position

- Some basics

- What is PID?

- Understanding

Feedforward

- Tuning Proceedure

- DCBM DC Brushed Motors

- Changing PID

values with Axis Machine/Calibration

- Manual tuning

-

- Velocity vs torque mode

tuning

- Torque Tuning

- Velocity tuning

- Links

- Spindle

- Endocder - hostmot2

- Pins:

- tmp

- Display screens - GUI

- Axis

- Modes of Operations

- Gmoccapy

- gladevcp - added to other

bits

- Homing settings

-

- ini

- Touch Probe for linuxcnc 2.9

- Settings

- auto zero

- Gcode generators

- General CNC notes

Disclaimer

This information HAS errors and is made available

WITHOUT ANY WARRANTY OF ANY KIND and without even the

implied warranty of MERCHANTABILITY or FITNESS FOR A

PARTICULAR PURPOSE. It is not permissible to be read by

anyone who has ever met a lawyer or attorney. Use is confined to

Engineers with more than 370 course hours of engineering.

If you see an error contact:

+1(785) 841 3089

inform@xtronics.com

LinuxCNC

Installing under

buster - for mesa

sources.list lines:

deb http://buildbot.linuxcnc.org/ buster master-rtpreempt

deb-src http://buildbot.linuxcnc.org/ buster master-rtpreempt

Do not use RTAI real time kernel! - use Preempt-RT

(pae PREEMPT_RT ) - install linux-image-rt-amd64

Linux Command line

Add isolcpus=2,3 ???

Disable cstates in the BIOS/ kernel command line -

intel_idle.max_cstate=0 ??

LinuxCNC acronyms,

abbreviations, special terms, file-types

BLDC - BrushLess DC [motor]

Comp - hal compiler tool

EMCIO - module of linuxcnc for non aixs i/o

EMCMOT module of LinuxCNC that handles the actual motion of the

cutting tool.

hmid - HostMot ID (references the IDROM in HostMot2 firmware) IDROM

specifies what features are included in a specific bitfile and the

functions of the I/O pins

(hmid = Host Mot (Host Motion)

ID = Host based Motion Control -- as in Ethernet host )

hal - Hardware Abstraction Layer - not to be confused with the old

linux hal system of the same name.

ihs - Initial Height Sense

MDI Manual Data Input

NML(Neutral Message Language) - not sure - not in use?

sserial - Smart Serial

Special terms

joint - A joint is one of the movable parts of the machine. not to

be confused with axis.

Kinematics - relationship between world coordinates and joint

coordinates of a machine. There are two types of kinematics. Forward

kinematics is used to calculate world coordinates from joint

coordinates. Inverse kinematics is used for exactly the opposite

purpose.

pin -

File-types

- ini - this file normally named machine-name.ini It is

the base file that points to all the other config files.

LinuxCNC on start up looks for ini file found in a directory in

~/ linuxcnc/configs/machine-name

- pncconf one directory up ls

- vhd - vhdl file???

- xise - files are Xilinx ISE project files - not really

LinuxCNC related

- ucf - ucf files are pin constraint files for Xilinx ISE

- pin .pin files are text representations of the IDROM content

- bit - bitfile used by mesaflash - binary configuration files

for Xilinx FPGAs

Create Ethernet

connection to Mesa card (this example used i793)

Set your jumpers so you are in the Default mode ( 7I93 W4 and

W3 down ) - this will come up with the default IP address

192.168.1.121

You will need mesaflash installed. Linuxcnc must NOT be running.

First set the NIC to use 192.168.1.240 by creating

/etc/network/interfaces.d/local

With contents:

#linuxCNC mesa interface

auto [your-mesa-NIC-device-name]

iface [your-mesa-NIC-device-name] inet static

address 192.168.1.240/24

hardware−irq−coalesce−rx−usecs 0

Then do

$ ifup your-mesa-NIC-device-name

If the other interface is using the common 192.168.1.0/24 network,

you will probably need to shut it down temporarily with

$ifdown [your-other-NIC-device-name]

testing:

With the 7I93 powered and connected to the Ethernet device used

above, try to ping 192.168.1.121

Then try

mesaflash --verbose --device 7i93 --addr 192.168.1.121

You should get some nice information back - you now should have

Ethernet communications with the mesa card.

Change IP to non

LAN network

In this example, we avoid the common 192.168.1.0/24 network by

setting the Mesa card to 192.168.10.10 and the NIC to

192.168.10.1 both will use the 192.168.10.0/24 network address

space :

$ mesaflash --verbose --device 7i93 --set ip=192.168.10.10

Look at the output - verify that space 2 has ip address:

192.168.10.10

This is now the IP address for the FIXED FROM EEPROM or non DEFAULT

mode - ONLY (DEFAULT mode IP stays the same).

It is time to powerdown and change the W3 jumper to 'up' to set the

card to use FIXED From Eprom mode.

Power the card back up.

Update /etc/network/interfaces.d/local

#linuxCNC mesa interface

auto [your-NIC-device-name]

iface [your-NIC-device-name] inet static

address 192.168.10.1/24

# address 192.168.1.240/24

# If using intel ethernet that in some cases looses the connection you might need

# hardware−irq−coalesce−rx−usecs 0

Clear the arp cache and restart networking

$ ip -s -s neigh flush all

$ systemctl restart networking

Test again - with

mesaflash --verbose --device 7i93 --addr 192.168.10.10

Write bit file to

mesa card

This example assumes 7i93_svss4_8d.bit firmware would be appropriate

This file is not found in a zip file from Mesa - not in a Deb

package.

$ mesaflash --addr 192.168.10.10 --device 7i93 --write 7i93_svss4_8d.bit

Should write and auto verify -

--$ mesaflash --addr 192.168.10.10 --device 7i93 --reload

If using intel ethernet that in some cases looses the connection,

there should be the following line added in a terminal? ??

sudo ethtool -C eth0 rx-usecs 0

mesaflash syntax:

$ measaflash --help

Do not confuse --serial with --sserial

--verbose is your friend

List pins of the 7i29

$ mesaflash --device 7i93 --addr 192.168.10.10 --readhmid

information about all sserial remote boards

$ mesaflash --verbose --device 7i93 --addr 192.168.10.10 --sserial

Get pins of a mesa board:

$ halcmd show all |grep 7i84

Mesa config

wizard

See http://linuxcnc.org/docs/html/config/pncconf.html

Computer response time -- Check for SMI (Slimy Management

Engine) problems - 120 seconds - ( change to 3600 - or even more )

$ perf stat -a -A --smi-cost -- sleep 120

The management engine is why LinuxCNC does not do well on many

brand new computers. Keep an eye out for coreboot

compatibility - current status is not good(2020).

HP Compaq Elite 8300 Base Model Convertible Minitower PC jitter

measurement :

Max 1,005,664 - jit 5920

Base 33,517 jit 8517

Connection to

7i84D vis 7i44

Mode is set via sserial_port_0=00000000 - 0 = mode-0 , 1

= mode-1 for details see $ man hostmot2

7i29 notes

- CR13 and CR14 light when it starts overriding the duty-cycle

to current limit.

- It is possible to home by hitting a mechanical limit (at the

very lowest speed) which would trigger a following error.

Move back a mm and call it home. more at

https://www.forum.linuxcnc.org/27-driver-boards/39589-7i29-amp-fault-output-pins

- Always use differential encoders" (RS422)

Encoder notes

Index-mask - hardware input that masks the index input signal

INI file notes

1 machine unit = 1 LINEAR_UNITS as set in the [TRAJ] section

hal file notes

Some component instances are generated by things in the ini file.

Nomenclature

Component - software Object?

Parameter - variables - set on instance at startup of component

hal-pin a feature of a component?

signal - equate

Syntax

setp - set pin or parameter

sets - set value of signal

net - connects signal to pin(s) - names signal

unlinkp - disconnect pin from signal

Components

Components all are supposed to have their own man page for pin

descriptions

inihal

iocontrol and

halui (they seem to have overlapping functions)

estop pins

described assuming no pins are yet interconnected:

iocontrol.0.emc-enable-in -- sets the Estop button displayed

in Axis - and

from the docs "Should be driven FALSE when an external estop

condition exists."

(False is the 'in' position)

iocontrol.0.user-enable-out becomes the OPPOSITE of

iocontrol.0.emc-enable-in if you click on the etop-button -

Does NOT change the appearance of the GUI estop button.

From the docs "FALSE when an internal estop condition

exists" (what defines an estop condition here? Are there other

things that can trigger an estop? ) This appears to be the

inverse of halui.estop.is-activated

iocontrol.0.user-request-enable iocontrol.0.user-request-enable (

output that 'PULSES' true if you click on estop button in axis AND

iocontrol.0.emc-enable-in is false (pulses on pulling-out

the GUI estop )

(iocontrol.0.user-request-enable is not completely documented in

the man page (2020))

There is a way (by writing a component) to latch

iocontrol.0.user-request-enable. That being said - it is an extremely

bad

idea to use this to enable a physical estop circuit -

which one should setup a way to disable the physical estop from

linuxcnc - but NOT enable it.

halui.estop.activate on rising edge activates

halui.estop.is-activated

halui.estop.reset on rising edge

resets halui.estop.is-activated

halui.estop levels won't prevent one from overriding with the axis

button.

Machine on-off

halui.machine.is-on ==>

halui.machine.off <==

halui.machine.on <==

Motion - accepts

NML motion commands, interacts with HAL in realtime

spindle.M.speed-out OUT FLOAT - Desired spindle speed in rotations

per minute From g-code S100 command.

All the spindle.M.speed-out.xxx come from g-code (Sxxx).

wj200_vfd

I am told that the cheap RS232 - to - RS485 converters steal

power from RTS and CTS so you might need to set them or use an

external power-supply for reliable operation.

First, you will want to find the page B-4 in the wj200 manual and

set A001, A002, C071, C072, C074, C075, C076, C077, and C078. Then

install mbpoll and test for basic modbus communications

$ mbpoll -a1 -Pnone -d8 -b115200 -r1 -c4 /dev/ttyS0

You should see something like this

-- Polling slave 1... Ctrl-C to stop)

[1]: 0

[2]: 0

[3]: 2

[4]: 0

Note that the driver is loaded with wj200_vfd but the pin names

follow the HAL convention and use wj200-vfd

wj200 defaults to --device=/devS0 --parity none --databits 8

--stopbits 1 --baud 9600

limit2 component

Keeps a float value between min and max - and dx/t under maxv

PID loop position

Some basics

Error = command - measured

Output = Error * PGain + (Integral of Error) * IGain + dError/dt *

DGain + FF0 * command + FF1 * dCommand/dt

Where - FF1 is velocity-feedforward

output = bias + (pgain * tmp1) + (igain * error_i) + (dgain *

error_d);

output += (command * FF0gain) + (cmd_d * FF1gain) + (cmd_dd *

FF2gain);

,.,.

FF0 adds a portion of the command to the output (minimize error

build up - best guess without feedback) normally set to o

FF1 adds a portion the first derivative of the command to the

output (compensates for friction or Motor CEMF ) Normally set

to 1 - adjust output scale so it is true.

FF2 adds a portion of the second derivative of the command to the

output (proportional to acceleration thus a command that is

increasing speed might need a bit of and extra kick to overcome

inertia)

FF3 third derivative -- proportional to jerk (Change in

acceleration )

MIN_FERROR = 1.0 amount of following error (distance in machine

units) allowed at very low velocity

FERROR = 10.0 distance allowed during rapid moves. - permitted

Ferrors are interpolated between these two numbers for speed.

H-bridge Tuning - Servo loop

What is PID?

PID loops are used in all sorts of systems, from temperature

control, to advanced pressure regulators.

P - is Proportional feedback - it takes the error

times a constant and adds it to the drive output. It is similar to

the corrections one makes with the gas pedal of a car - if we are

going a bit too slow, we don't floor it, we just press a proportional

bit harder depending on the magnitude of the error.

The original proportional only controllers go back to Huygens

pendulums and latter Watts flying balls. The math behind all this

was first explored by non other than James Clerk Maxwell in 1868

I - is Integral feedback - it takes the average

error over time times a constant - and adds it to the drive output

( improves fine accuracy)

D - Is Derivative feedback - it takes the change

in error times a constant and adds it to the drive output (

reduces errors when the load suddenly changes)

Understanding

Feedforward

While P(proportional) feed-back works - if you turn it up very high,

it will oscillate - same with D - same with I. So what would

be good is if we can give a drive value that is close to what is

needed and use PID for fine corrections of error. So for any

change in motion - d/dt - we want a value to send that should give

something close to the correct response - that is called feedforward.

This brings us to OUTPUT_SCALE which should be set to the

speed obtained by giving full output to the drive. Thus a

motion request scaled to OUTPUT_SCALE should get us close to the

correct output. If OUTPUT_SCALE is correct, FF1 should

equal 1. This adds to the output value a pretty good guess to

what it should be - and the PID section looks at any errors and

sends correcting additions or subtractions to the output.

Tuning Proceedure

This assumes you already know how to use the calibrate command -

and HALscope.

- Set DEADBAND to 1 machine resolution step * 0.6

- Start with P, I and D FF0 and FF2 at zero

- Set jog speed to 50 mm/min - know where your PHYSICAL ESTOP

switch is and be sure it works - be ready to press it.

- FF1=1 and increase P slowly so things can move - verify

direction, limits, and homing.

- Set P to low value - about 1/4 any possible oscillation.

Oscillations can allso be caused by OUTPUT_SCALE being way

off.

- Set OUTPUT_SCALE to encoder.N.velocity when pwmgen is

pedal-to-the-metal. We are finding the maximum speed the table

can move! This means changing things in ini so you can

move things at dangerous speeds - work smart -

this is dangerous - if you don't know exactly

what you are doing - don't )

- If you are OK with the danger - for the axis under tuning

you will need to temporarily greatly increase FERROR,

MAX_VELOCITY. In the [DISPLAY] section set MAX_LINEAR_VELOCITY

to something insane. (I could not change this via the

calibration window - had to edit the ini file and restart)

- MAX_ACCELERATION - plot the velocity feedback in

Halscope and max out acceleration. The slope of that will be the

physical max - you will want to set to something like 90% of

this (Perhaps a bunch less? No reason to

hotrod..)(MAX_ACCELERATION has to be correct for tuning to work

- if you ask a PID loop to accelerate things faster than

possible - the numbers saturate and clip).

- Getting FF1 correct and accurate is key - other things won't

work if it is wrong. It will be correct if you measure - no

guessing.

- Be sure jog speed is quite low - start with 50mm/min

- Set up the HALscope to look at f-error, motor-pos-command, and

pos-relative for the axis you are working on.

- Start up the Calibrate window.

- Increase P slowly until you get a slight overshoot - something

that looks like a damping factor of 0.4-0.7 - increase jog

speed.

- Double the jog speed and repeat the step above. - keep

doubling until you get to something like 1000mm/min

- FF1 - Start with a very low number - 0.01 Increase slowly -

Tune to eliminate start and stop over/under shoots (about 0.005%

of P).

- Set FF2 so that the actual position does not lead or lag the

commanded position during acceleration

- Increase I until you start to see oscilations in FERROR

Once this tuning is finished - set [TRAJ]MAX_LINEAR_VELOCITY

approx 20% higher than the axis settings.

G-code is sort of ignorant of acceleration - one would want

to set MAX_ACCELERATION to something sane.

Don't forget to return FERROR, MAX_VELOCITYt

MAX_LINEAR_VELOCITY to operating settings.

Checks - compare pwmgen.N.scale to OUTPUT_SCALE

DCBM DC Brushed

Motors

A DC motor gets a speed from this equation where ω is the rotation

in radians:

ω = V/k - TR/k^2

k and R are constants - but k in the torque term it is squared so

less of a factor (torque load slows things down a bit) so I see this

as mostly a velocity input device. The slowing of the speed by tool

force has to be corrected by the PID loop. We test at full

posible speed to find OUTPUT_SCALE so that the second term of the

above equation is insignificant.

speed for the test?

buzzyness?

increase P speed? damping?

Set D below buzzyness - ( a few wiggles in

f-error plot ? )

Set FF1 so that the actual position does not lead or lag

the commanded position at full speed

Set FF2 so that the actual position does not lead or lag

the commanded position during acceleration

Increase P as much as possible without causing overshoot

Increase I below but close to instability. No slow

hunting oscillations..

Changing PID

values with Axis Machine/Calibration

This window makes temporary live changes of PID parameters - that

you enter - after you press 'test'. One has to press Test

- try the setting - then press Cancel to make

the next change - rinse - repeat..

While in test - one has to create the move via Jog.

Normally you would monitor joint.N.f-error with the halscope...

Manual tuning

Set I and D to zero - set P to 1/2 value where it starts to

oscillate ( overdamped - no overshoot )

Increase I to instability - set to 1/2

increase D to instability - set to 1/2

Ziegler–Nichols method

https://en.wikipedia.org/wiki/Ziegler%E2%80%93Nichols_method

FF1, its the most important tuning number for velocity mode drives

Before tuning - remove all the PID maxerror lines in the hal file ..

FF1 should be set to within 1/10 1%

For a velocity mode servo (when the drive is tuned properly) D is

_not_ appropriate and FF1 is arguably the most important tuning

parameter.

Velocity vs torque

mode tuning

They are NOT the same - so two subsections below

For both modes -

If OUTPUT_SCALE is set so PID output is in machine units per second

then the PID values are "normalized" so inch and mm machines will

have comparable PID numbers and things

like FF1 will make sense (FF1 will be 1.00 if the scaling is

correct). Watch pwmgen.N.value and encoder.N.velocity

with the halmeter and change OUTPUT_SCALE until they are close to

matching.

For spindles

Torque Tuning

Start with FF1=0 and FF2 = 0 and I=0

Chose a small amount of P (say 50 = full torque with 1/5" error)

Then increase D until it gets too "buzzy" and then back off about

30% on D

Then increase P until you get oscillations and again back off about

30%

Then adjust FF2 so that you neither overshoot or undershoot during

acceleration (the FF2 setting is inertia dependent so its better to

do this with a typical table load)

Finally increase I until motion becomes unstable (Watch out for WIDE

oscillations here)

and back off about 50%

Another take - Increase D to oscillation - then set at 1/2

Increase P to oscillation - then set to 1/2

Add FF2 to tune out accel-undershoot - and decel-overshoot.

Carefully - add I to oscillation - then set at 1/4

Velocity tuning

For a velocty PID loop probably the most important part is FF0

If the PID feedback, command and output are all in RPM, FF0 should

be 1.0)

If you have only FF0(all other PID terms=0), you are running open

loop

(because the PID output is just FF0*Command)

Using the FF0 feedforward term make the PID output approximately

correct before any

feedpack is applied. This makes the P and I terms have less work to

do...

Links

http://support.motioneng.com/Downloads-Notes/Tuning/default.htm

Servo tunning:

https://forum.linuxcnc.org/10-advanced-configuration/32367-servo-tuning-detailed-how-to

https://gnipsel.com/linuxcnc/tuning/servo.html

Spindle

# set the encoder to non-quadrature simple counting using A only.

setp hm2_7i93.0.encoder.04.counter-mode true

http://linuxcnc.org/docs/devel/html/drivers/hostmot2.html#sec:hm2-encoder

G33 centric -

spindle.N.at-speed

motion.coord-error OUT BIT TRUE when motion has

encountered an error, such as exceeding a soft limit

motion.coord-mode OUT BIT

spindle.N.revs

spindle.0.speed-out-abs comes from g-code s command..

wj200-vfd.0.commanded-frequency sets motor speed..

- two speeds thus hm2_7i93.0.encoder.04.scale set via

mux2

# set the HAL encoder to 60 pulses per revolution.

setp hm2_5i25.0.encoder.02.scale

400

# set the encoder to quadrature counting using A and B .

setp hm2_5i25.0.encoder.02.counter-mode false

# connect the HAL encoder outputs to LinuxCNC.

#net spindle-position-soft encoder.0.position =>

motion.spindle-revs

net spindle-velocity hm2_5i25.0.encoder.02.velocity =>

motion.spindle-speed-in

net spindle-index-enable hm2_5i25.0.encoder.02.index-enable

<=> motion.spindle-index-enable

#spindle_orient

net spindle-position-0to1 hm2_5i25.0.encoder.02.position =>

orient.position => orient-pid.feedback =>

motion.spindle-revs => near.0.in1

net orient-angle motion.spindle-orient-angle =>

orient.angle

net orient-enable motion.spindle-orient => mux2.0.sel =>

or2.0.in1 => and2.0.in1 => orient-pid.enable =>

orient.enable => and2.1.in0

#####setp timedelay.0.on-delay 2

#####setp timedelay.1.on-delay 1

#######net spindle-in-position near.0.out => timedelay.0.in

=> timedelay.1.in

#######net spindle-in-position5 timedelay.1.out =>

and2.1.in1

#######net spindle-in-position8 or2.2.out =>

parport.0.pin-02-out

net spindle-in-position10 or2.2.out =>

parport.0.pin-02-out

net spindle-in-position9 and2.1.out =>

or2.2.in1

net spindle-in-position8 or2.2.in0 <=

motion.spindle-locked

net spindle-in-position7 parport.0.pin-13-in => or2.1.in0

#####net spindle-in-position2 timedelay.0.out => and2.0.in0

#####net spindle-in-position2 timedelay.0.out => or2.1.in1

net spindle-in-position3 or2.1.out => and2.0.in0

net spindle-in-position4 and2.0.out =>

motion.spindle-is-oriented

setp orient-pid.maxoutput 0.25

setp orient-pid.Pgain

10

# 4.1

setp orient-pid.Igain

0

setp orient-pid.Dgain

0

setp orient-pid.FF1

0.0013

setp orient-pid.FF2

0.0002

setp orient-pid.deadband 0.001

setp near.0.difference 0.01 # (3.6 degrees)

############# End Spindle Encoder #############

#and then connect the encoder to the 7I76's encoder input

net spindle-vel-cmd-rps

<= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <=

motion.spindle-speed-out-rps-abs

net spindle-vel-cmd-rpm

<= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <=

motion.spindle-speed-out-abs

net

spindle-enable

motion.spindle-on => or2.0.in0 ######*#

net

spindle-cw

<= motion.spindle-forward #temp test orientate

net

spindle-ccw

<= motion.spindle-reverse

net

spindle-brake

<= motion.spindle-brake

net

spindle-at-speed

=> motion.spindle-at-speed

#These lines in hal gave sensible readings on the halscope. Note

the scale now the same as scale in the ini file.

#These settings get pwm on gpio008 working

setp hm2_5i25.0.pwmgen.00.output-type 1

setp hm2_5i25.0.pwmgen.00.scale 36

setp hm2_5i25.0.pwmgen.pdm_frequency 5000000

setp hm2_5i25.0.pwmgen.pwm_frequency 5000

net spindle-vel-cmd-rps => mux2.0.in0

net selected-spindle-vel-cmd-rps mux2.0.out =>

hm2_5i25.0.pwmgen.00.value

#change num_pwmgens=0 to num_pwmgens=1(note this cannot be

selected in Pncconfig 5i25/7i76)

setp hm2_5i25.0.gpio.025.invert_output true

#net spindle-enable => hm2_5i25.0.pwmgen.00.enable #comment out

for orient mod

net spindle-enable => or2.0.in0

net selected-spindle-enable or2.0.out =>

hm2_5i25.0.pwmgen.00.enable ######*#=> hm2_5i25.0.gpio.017.out

Endocder -

hostmot2

Pins:

(s32 out) count

Number of encoder counts - up and down - since the previous reset.

(float out) position

Encoder position in position units (count / scale).

(float out) velocity

Estimated encoder velocity in position units per second.

(float out) velocity-rpm

Estimated encoder velocity in position units per minute.

(bit in) reset

When this pin is TRUE, the count and position pins are set to

0. (The value of the velocity pin is not affected by

this.) The driver does not reset this pin to

FALSE after resetting the count to 0, that is the user's job.

(bit in/out) index-enable

When this pin is set to True, the count (and therefore also

position) are reset to zero on the next Index (Phase-Z) pulse.

At the same time, index-enable is re‐

set to zero to indicate that the pulse has occurred. (Is This is an

edge triggered event? ) The motion component sets

spindle.S.index-enable (in/out) to TRUE at the beginning of a

spindle-synchronized move (Thus zeroing the spindle count - at the

start of the spindle-synchronized move. )

(s32 out) rawcounts

Total number of encoder counts since the start, not adjusted for

index or reset.

(bit out) input-a, input-b, input-index

Real time filtered values of A,B,Index encoder signals

(bit in) quad-error-enable

When this pin is true quadrature error reporting is enabled.

when false, existing quadrature errors are cleared and error

reporting is disabled

(bit out) quad-error

This bit indicates that a quadrature sequence error has been

detected. It can only be set if the corresponding

quad-error-enable bit is true

(u32 in) hm2_XXXX.N.encoder.sample-frequency

This is the sample frequency that determines all standard encoder

channels digital filter time constant (see filter parameter)

(u32 in)

hm2_XXXX.N.encoder.muxed-sample-frequency

This is the sample frequency that determines all muxed encoder

channels digital filter time constant (see filter parameter) This

also sets the encoder multiplex‐

ing frequency

(float in) hm2_XXXX.N.encoder.muxed-skew

This sets the muxed encoder sample time delay (in ns) from the

multiplex signal. Setting this properly can increase the

usable multiplex frequency and compen‐

sate for cable delays (suggested value is 3* cable length in feet

+20)

(bit in) hm2_XXXX.N.encoder.hires-timestamp

When this pin is true the encoder timestamp counter

frequency is ~10 MHz when false the timestamp counter frequency is

~2 MHz. This should be set true for fre‐

quency counting applications to improve the resolution. It should be

set false when servo thread periods longer than 1 ms are used.

Parameters:

(float r/w) scale

Converts from 'count' units to 'position' units.

(bit r/w) index-invert

If set to True, the rising edge of the Index input pin triggers the

Index event (if index-enable is True). If set to False, the

falling edge triggers.

(bit r/w) index-mask

If set to True, the Index input pin only has an effect if the

Index-Mask input pin is True (or False, depending on the

index-mask-invert pin below).

(bit r/w) index-mask-invert

If set to True, Index-Mask must be False for Index to have an

effect. If set to False, the Index-Mask pin must be True.

(bit r/w) counter-mode

Set to False (the default) for Quadrature. Set to True for

Step/Dir (in which case Step is on the A pin and Dir is on the B

pin).

(bit r/w) filter

If set to True (the default), the quadrature counter needs 15 sample

clocks to register a change on any of the three input lines (any

pulse shorter than this is

rejected as noise). If set to False, the quadrature counter

needs only 3 clocks to register a change. The default encoder

sample clock runs at approximately 25

to 33 MHz but can be changed globally with the sample-frequency or

muxed-sample-frequency pin

(float r/w) vel-timeout

When the encoder is moving slower than one pulse for each time that

the driver reads the count from the FPGA (in the hm2_read()

function), the velocity is harder to estimate. The

driver can wait several iterations for the next pulse to arrive, all

the while reporting the upper bound of the encoder velocity, which

can be accurately guessed. This parameter specifies how long

to wait for the next pulse, before reporting the encoder

stopped. This parameter is in seconds.

(s32 r/w) hm2_XXXX.N.encoder.timer-number

(default: -1)

Sets the hm2dpll timer instance to be used to latch encoder

counts. A setting of -1 does not latch encoder counts. A

setting of 0 latches at the same time as

the main hostmot2 read. A setting of 1..4 uses a time offset

from the main hostmot2 read according to the dpll's timer-us

setting.

Typically, timer-us should be a negative number with a magnitude

larger than the largest latency (e.g., -100 for a system with

mediocre latency, -50 for a system

with good latency).

If no DPLL module is present in the FPGA firmware, or if the encoder

module does not support DPLL, then this pin is not created.

When available, this feature should typically be enabled.

Doing so generally reduces following errors.

tmp

Servo-loop link

https://forum.linuxcnc.org/24-hal-components/38141-closing-the-servo-loop-with-hal-mesa-7i76

Building LinuxCNC

https://gnipsel.com/linuxcnc/uspace/debian9-eth.html

GUI Frontends

axis - solid

Gscreen (uses gladeVCP) PathPilot??

TkLinuxCNC GUI

hazzy new

Display screens -

GUI

Qtvcp is an infrastructure to display a custom CNC screen or control

panel in LinuxCNC. It displays a UI file built with the QTDesigner

screen

Gmoccapy

nativeCAM seems like a key feature.

Axis

As of 2.8 put a file in ~/linuxcnc/misc/axicrc to fix up things.

Default screensize:

max size root_window.tk.call("wm","geometry",".","1900x1200")

# or - To have Axis open up at the maximum size for

your screen use:

#maxgeo=root_window.tk.call("wm","maxsize",".")

#fullsize=maxgeo.split(' ')[0] + 'x' + maxgeo.split(' ')[1]

#root_window.tk.call("wm","geometry",".",fullsize) #for now

root_window.tk.call("wm","geometry",".","1600x1000")

Manual [F3]- manual control tab

The axis can be selected and jogged here.

Touch Off

The Axis GUI rather hides what is happening under the hood. (and

it also makes it too easy to get it wrong)

The touch-off button brings up a dialog, and in that you can

select a drop-down. The default is P0 which is the current

G54-G59-3 coordinate System.

P0 runs G10 L20

What then happens is G10 L20 PN, where N is the

dropped-down coordinate system

See

https://lrak.net/wiki/gcode.html

Tool Touch Off

G10 L10 Pn where n is the current tool number

MDI(Manual Data Input)[F5]

gladevcp - added to other bits

gladevcp gives a fairly useable interface to create GUIs..

To test -

gladevcp_demo -H custom.hal gvcp-panel.ui

During test - run

halcmd show all

This gets you the pin names.. you can also run

halmeter. The names are not consistent -

gvcp-panel.motor_current gets set as gladevcp.motor_current

in custom_gvcp.hal

The ini file tells gvcp where to look for the python handlers.py

file in this line: GLADEVCP= -u handlers.py -H

gvcp_call_list.hal gvcp-panel.ui

Homing settings

ini

[TRAJ]

NO_FORCE_HOMING =

HOME =

POSITION_FILE =

[JOINT]

HOME =

HOME_OFFSET =

Touch Probe for

linuxcnc 2.9

https://forum.linuxcnc.org/49-basic-configuration/29187-work-with-probe?start=640#276444

- install using the instructions from

https://github.com/verser-git/probe_screen_v2.8

/python

/psng

need to be copied or linked in to ~/linuxcnc/configs/machine-name/

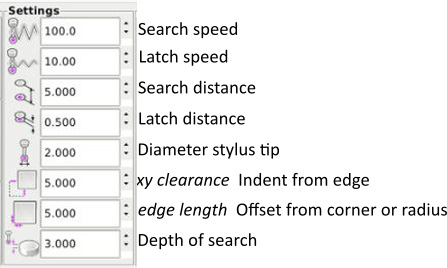

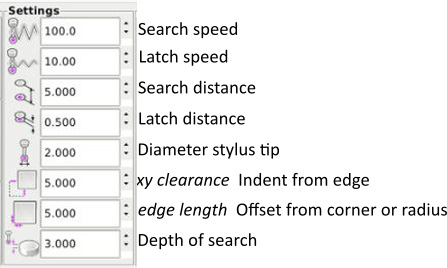

Settings

- start VERY conservatively.. with something the probe can push..

auto zero

Gcode generators

https://github.com/linuxcnc/simple-gcode-generators

https://www.warrensbrain.com/gcode-to-english-translator.html

Email