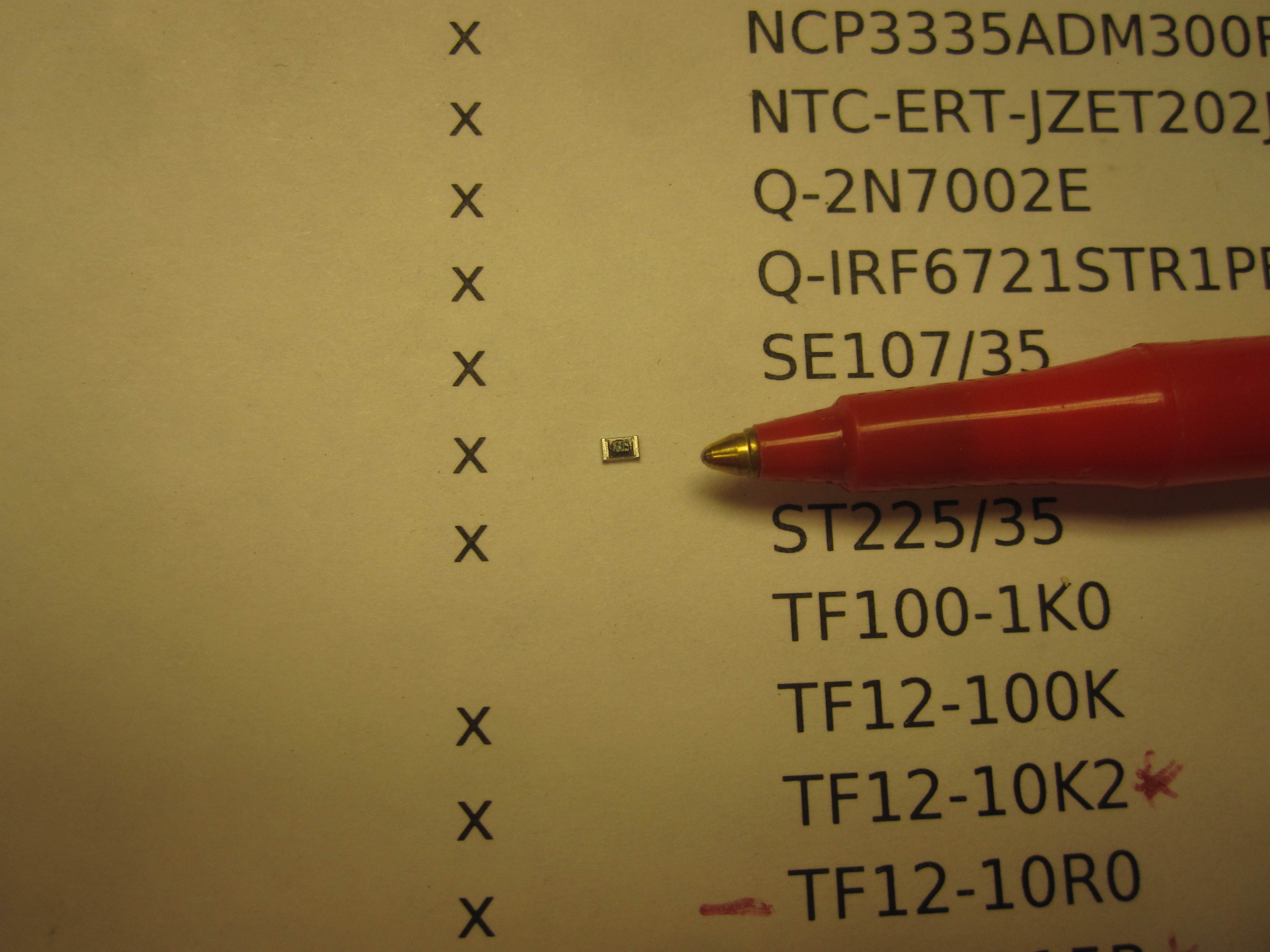

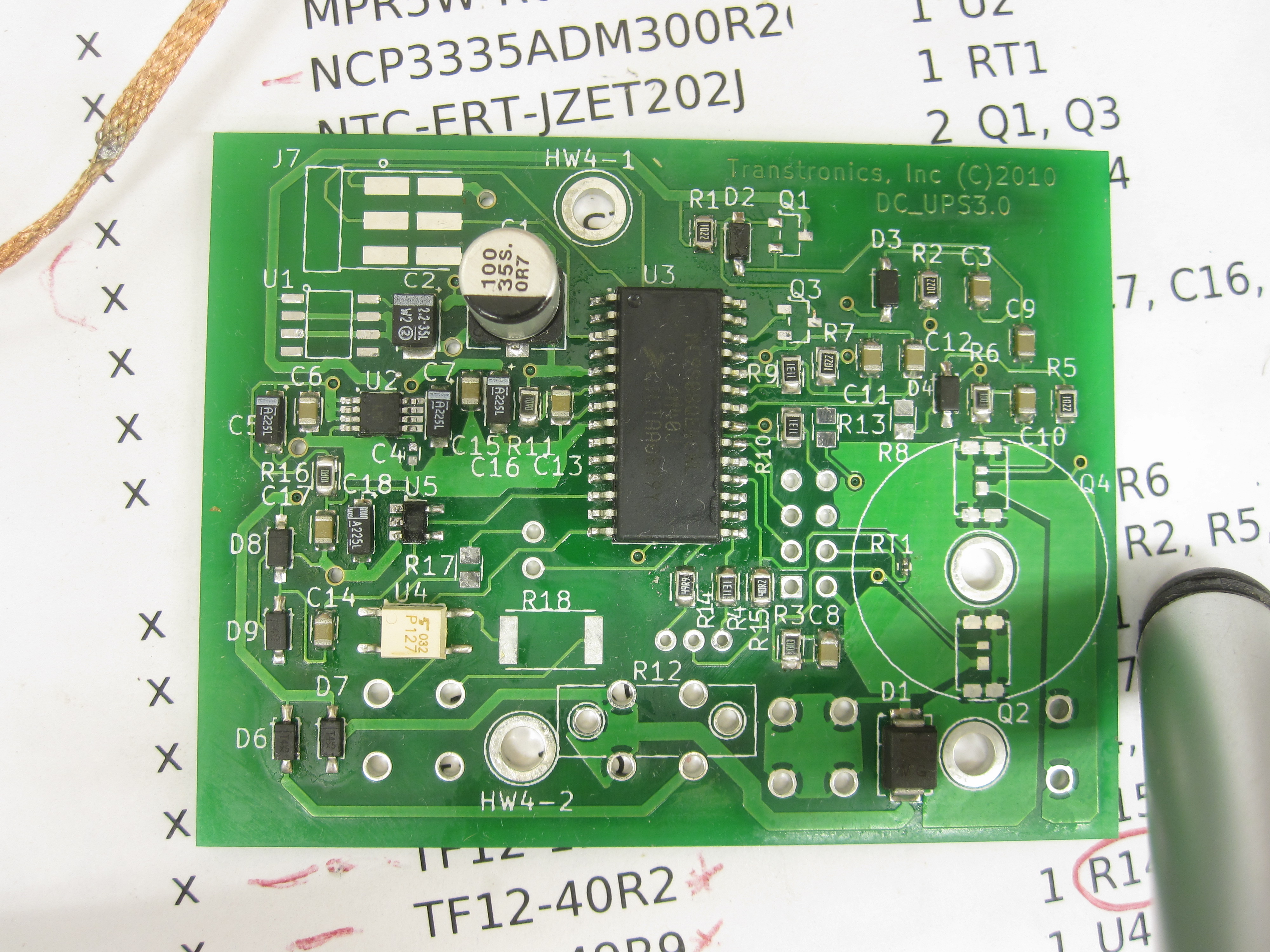

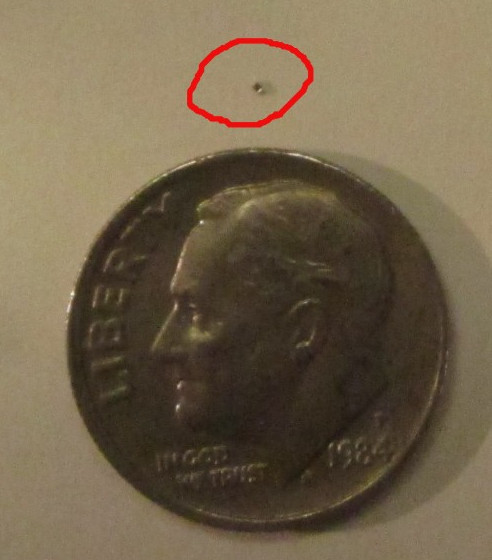

This is not the smallest part – there is a much smaller thermistor below.

Sneezing is not a good idea.

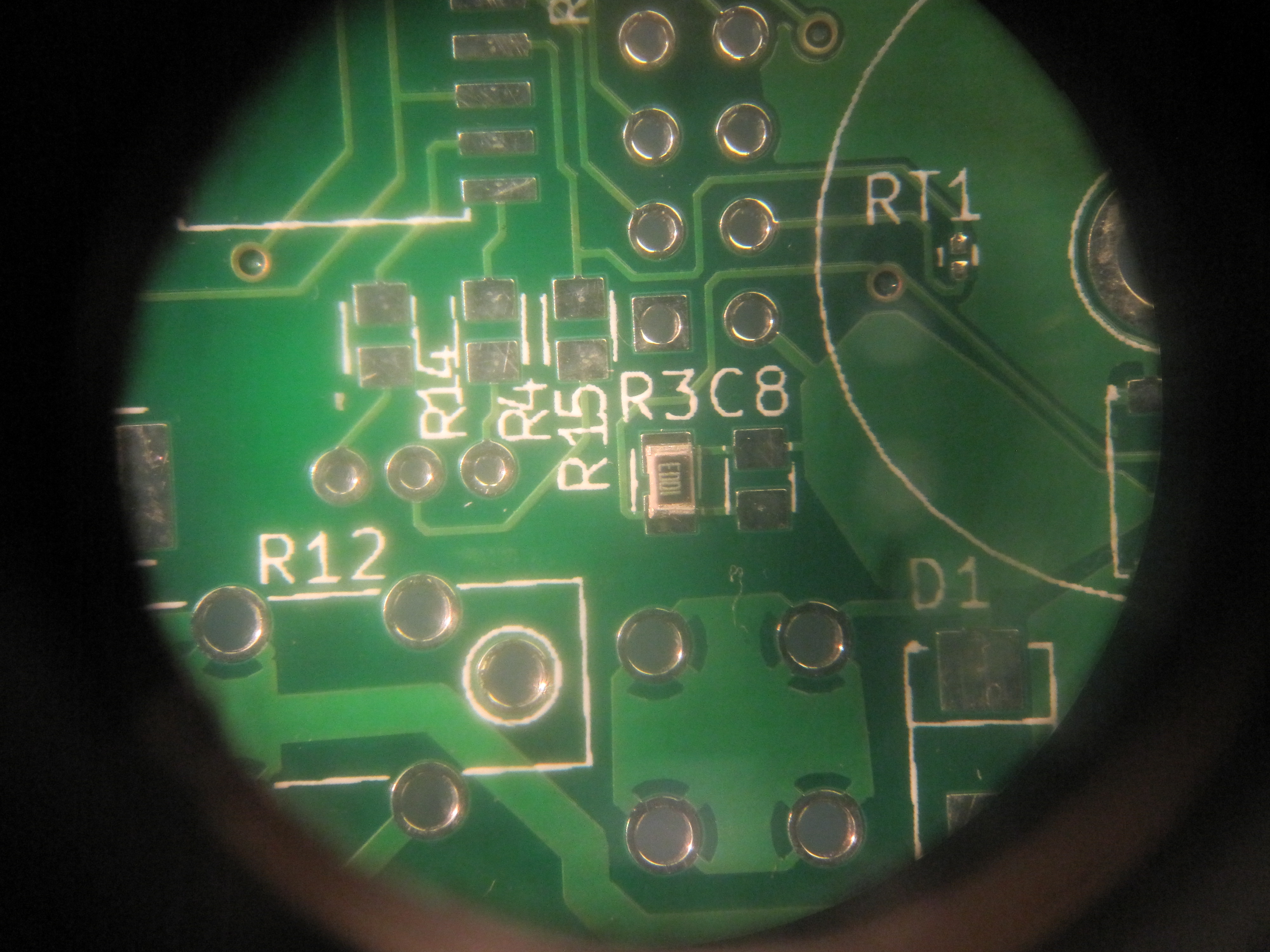

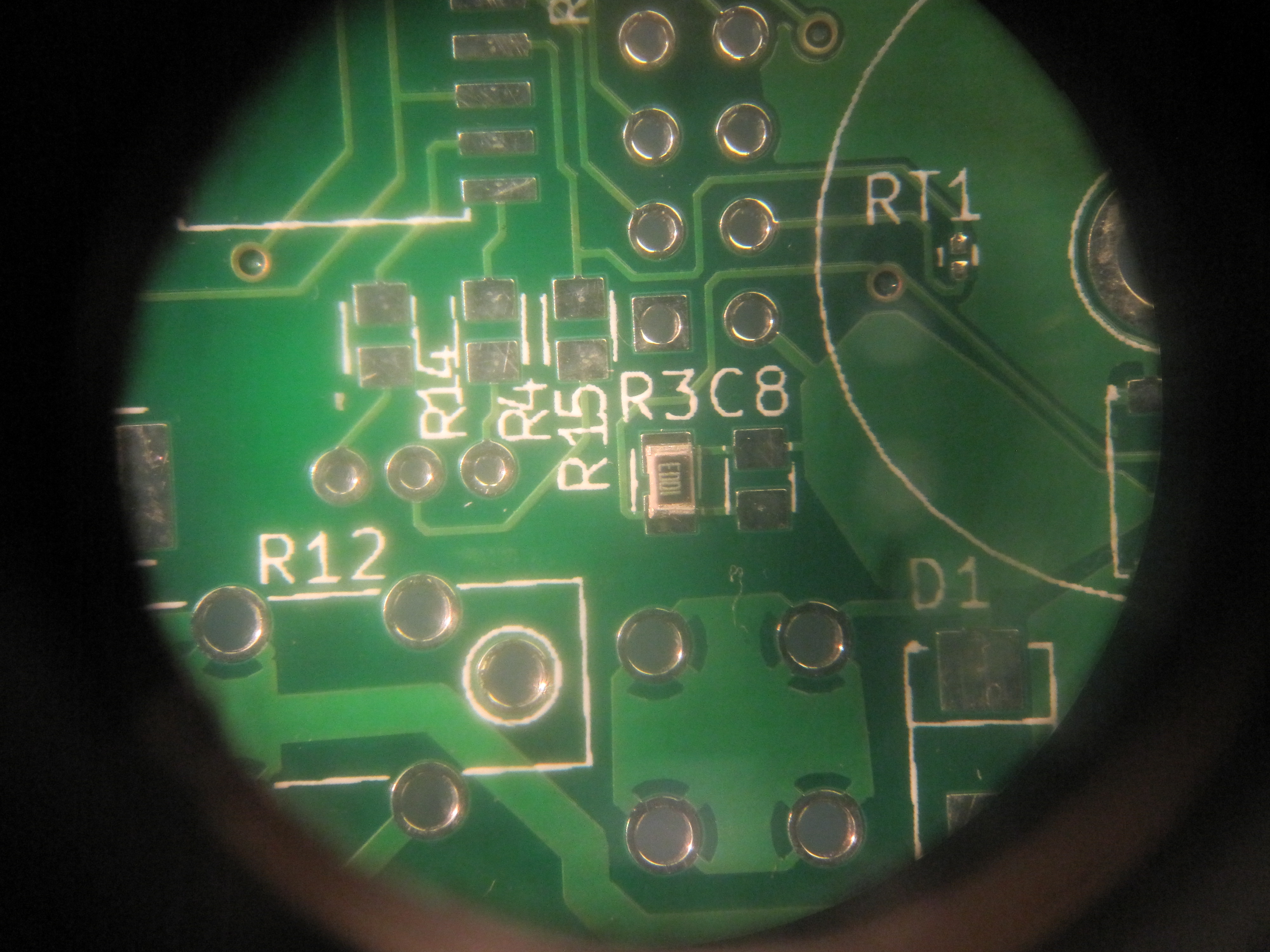

I did my best to take a picture through the eye piece of the

scope. R3 is the same resistor placed ready for me to solder.

It is easy to bump the part out of alignment – small steady motions – sometimes the surface tension of the solder causes ‘tombstone-ing’ where the part stands up on one end.

Once this is all assembled, these will normally be put together by robots – the solder is applied via stencils and then into a infrared oven to melt the solder.

I installed a 0204 thermistor tonight – by far the smallest part

I’ve ever soldered. On the first attempt, the surface tension of

the solder just picked it up and stuck it to the soldering iron. I

re-positioned it and then carefully laid a tiny corner of a

circuit board on to to hold it in place. I don’t really need one

this small, except it is the only one that is thin enough to match

the FETs I’m using. It is the speck in the red circle

– (not the best picture)

Small enough that just breathing moves it around – I had to be

careful to breath slowly..

Any smaller and it would be dust!