Wells Index Serial

#20567 Model 810

- Wells Index Serial #20567 Model 810

- Wells machine Specifications

-

-

- Pendant

- Motherboard

- Mesa cards (Looks like mesa

is the deal?)

- Linuxcnc - see linuxcnc

- Scales (linear encoders)

- Spindle

- Spindle motor

- Hitachi WJ200-022SF inverter

- WJ200-022SF

Settings

- Spindle encoder

- Drive DC supply

- Homing Notes

- Servo motors

- Distance between pinon gear

base and motor base:

- Gear ratio

- 2 are IIC Inc. MT30U4-36

(M4-2959A) - now all 3

- The other Milltronics

MT30U4-38 -Spindle

- Encoders on the motors:

dynamics research corp encoder 152-021-500-18UJ

- Lubes

- Way covers

- Tramming the nodd

- Kwik-Switch - on the tapers

page

- Ball-screws

- Saddle and table ball-screw

bearings

- Z-axis ball screw

- Spindle

- Sandwich Assembly

- Important things not to be

missed

- Adjusting the end-play

- BACK GEAR - not really -

does not reverse!

- Removal of 3hp Spindle motor

- Procedure for removing

sandwich assembly for replacing oil seal in back gear

housing and other repairs.

- Reassembly of gear box

- Removinge motor variable

drive pulley spring assembly

- To remove vertical spindle

pulley (drive cone pulley - CAM housing)

- Assembling Cam housing

- Brake

- TO ADJUST THE SPINDLE

BRAKE:

- Spindle speeds

- Motor magnetic brake

- Bearings

- Size Weight

- Moving

- History

- Removing The Table

- Ram (AKA Overarm)

- Turret

- wiring

- Notes for similar machine

-

- INSTRUCTIONS FOR CHANGING

SPINDLES IN THE FOLLOWING MODELS 745. 747. 756, 757,

845, 847, 856, 857,760, 860, and 887.

- PROCEDURE FOR FREEING UP

BACK GEAR TO DIRECT DRIVE 745, 756, 760, 845, 856,

747, 757, 860, 847, and 857

- Precision limit switches

Wells machine

Specifications

Table size 228x 1168mm [9" x 46"] 5/8" T-slots

Travels

- x 812.8 [32"] ?? Wishful or not with full way

engagement? 660.4[26"] with way engaged

- y 304.8[12"] possible 305

- quill 132[5.25??]

- Knee 431;8 [17"]

- Overarm/ram 533.4[21"]

Original color ASA 49 grey

Pendant

VistaCNC http://www.vistacnc.com/b07_pendant_P1/pendant_p1A.htm

Motherboard

HP8300 -CMT ( have docs)

Mesa cards (Looks

like mesa is the deal?)

https://mesanet.com

"Anything I/O" does not meant what it says - only digital

signals.

- 7I93 Ethernet-2-two AIO-50pin card can drive

up to 4 7I29s $89

- 7I29 AIO50 to dual H-bridge driver - dual Encoder

Front (power side) are frame ground (only connect to motor

cable shield wire) $299 2x250ma .5A

- 7I37TA AIO-to-16/8 I/O opto isolated - breakout - no LED $79

- 7I44 Host-2 Eight Channel RS-422/485 interface/ RJ45

$69

- 7I84 RS422-to-32/16 + 2 quad counters - Breakout no LEDs

$79

- 7I73 RS422-to-16/4-2A (+4 quadrature counters? )

NO-breakout - no LEDs $49 - needs 40 and 34 pin breakouts

- 7I66-8 RS422-to-16/8 remote isolated digital - with

breakout + LED $79

Scales (linear

encoders)

SINO - have install manual

Need 3 scales

X KA300-720(1um)(RS422) Ali-ex $134.75 need length = 677 - extra

45mm

Y KA300-370(1um) Ali-ex 124.12 ???? need length =350 - extra 20mm

existing mount holes 470

Z KA200-140 (1um) Ali-ex $195.86 need length = spec=132(wrong)

actual 136

Aston Machinery Equipment Store?

All 9pin - Can you put together a package quote?

KA-200 supporting plate

KA300 supporting plate

KA300D enclosure or X

Guangzhou Lokshun CNC Equipment Ltd.

https://www.sino-ld.com/en/

Address: No. 17, Yunjun Road, Huangpu District, Guangzhou

Postal code: 510530

Tel: +86-020-66839300

Fax: +86-020-66839301

Spindle

Spindle motor

Model 10348-BL1964E Frame

AFA-912S

3-phase 60hz 3 HP

Max Ambient 50 - Continuous duty cycle.

Insulation code F (155°C - motor surface temp is 30° cooler - so

max surface is 125°C )

RPM (@60hz) 1800

Insulation System B (130°C )

230V - 9.*A

460V 4.9A

Hitachi

WJ200-022SF inverter

WJ200-022SF

Max baud 15,200

Brake resistor 35 - 100ohms 400Watt?

W -H - D 108 128 170.5 Needs 100mm top and bottom clearance and 50

mm sides..

Power in 30A

power Wire - MTW or UL1015

https://www.houwire.com/products/belden.asp/

https://www.distributorwire.com/blog/machine-tool-wire/

WJ200-022SF

Settings

The manual is seriously sub-optimal - Hitachi should be

embarrassed

PTC - settings

C005 - set 19 - ONLY if you have a 3k trip PTC thermistor

in place.

C085 - 93%

C085 sets scale factor for PTC - works backwards

- 150 trips at a lower resistance..

100% - trips at 3.19K

90% trips at 3.52K (10% higher)

KTY81/222 thermistor is 2k-2.04K @25°C with a TC of 0.79%/°K

Temp to Resistance KTY81/222

| °C |

R |

| 20 |

1941 |

| 25 |

2020 |

| 30 |

2100 |

| 40 |

2267 |

| 50 |

2441 |

| 60 |

2623 |

| 70 |

2812 |

| 80 |

3009 |

| 90 |

3214 |

| 100 |

3426 |

| 110 |

3643 |

| 120 |

3855 |

| 125 |

3955 |

| 130 |

4048 |

| 140 |

4208 |

| 150 |

4323 |

Main settings :

b037 04 unlocks params

A001 03 Freq-source = ModBus input

A002 03 Run command source = ModBuss

A003 60 Base frequency- motor rated frequency where we have max

torque and HP

A004 66 MAX freqiency - give a bit of head room.

A051 DC braking

A082 230 motor voltage AVR

C071 10 modbus baud rate 115,200

C072 01 ModBus addr

C074 00 No parity

C075 01 Stop bit

C076 01 Communication error = decelerates and trips

C077 00.0 Com error timeout 0 = disabled

C078 00 Com wait time - how long before reply

L terminal to deteSet 19 in C005.

H003 2.2 (2.2 or 3.7 ? ) KW rating of motor - ( could

increase )

H004 04 Motor poles

P012 ???

F001

F002 03 acceleration time sec

F003 03 deceleration time sec

b082 0.5 in hz Start frequency

Important to run the auto-tuning on the motor, ideally with the

belt off or in neutral drive position. (One can do a static

autotune if it isn't possible to disengage the drive)

Auto-tuning

set A001 02

set A002 02

set F001 60

Verify H003 motor size in kwh

verify H004 motor poles

verify A003 base frequency - (motor frequency)

verify A082 AVR voltage - motor voltage

verify A051 00 is off for tuning DC braking

H001 02 - Enabled with motor rotation

Press RUN - The motor will hum and then cycle up to 75% of

speed twice. When completed the display will s

_ _ _ o - completed or _ _ _ _ Failed

Press stop

Set H002 02

- set the VFD run to stop and then press the reset key on the VFD.

Go into the programming mode and set H002 = 02 and save, this will

load the motor auto tuning data.

Restore A001 A002 to 03

# lose all settings warning !!!!!!!!!!!!!!!

Factory reboot

Set B087 = 2

#####################

Might need some of below - don't think so - see manual

A039 = 04 jog stop controlled deceleration

# A042 = 5.0

# A044 = 03 this will give you full torque at low hertz.

A051 = 01 Enable DC braking

A052 = .25 freq DC braking starts

A054 = 60%

A061 = 60hz.

A062 = 8 hz.

B settings

B012 = Full load amperage on motor name plate.... mine is 8.6

B022 = 16.5 refer to page 59 of the quick ref. guide for the

formula

B038 = 201

B090 = 10.0 -

B095 = 02

B097 = set to 35

B130 = 01

B133 = 1.0

B134 = 5.0

F settings

F002 = .55 acceleration time

F003 = .75 deceleration time

Spindle encoder

https://pico-systems.com/bridge_spindle.html Used ATS667LSG

sensors

high speed = 22 counts = 1 rev or 154 counts = 7-revs

low speed = 248.857 counts = 1 rev or 1742 counts =7 revs

Drive DC supply

Voltage was 72V - 80Vac

Transformer NMI-1179 secondary 62, 86, 90Vac ...1750VA??

national-meter.?? - 127V peak

Capacitors 2 - in parrellel 8700uf@150Vdc - measure size..

Homing Notes

On a mill - home is typically with z all the way up, the saddle

out towards the operator and the table all the way to the right (

z ends up over the back left corner of the table).

Servo motors

Distance between

pinon gear base and motor base:

Z - 5.736mm

x -

Y

Gear ratio

16 tooth drive gear - 32 count ball gear - 2:1 1000 counts per rev -

1 turn = .2" or .0002" or .005 08mm

Ball screws are 0.200" per turn - if instead we use 508 counts

--1016 per rev -

.2" = 5.08mm thus one count would be 5um

with 5080 counts - one count would be 1um

2 are IIC Inc.

MT30U4-36 (M4-2959A) - now all 3

40inlb stall torque

max RPM 4000

volts 114

Current at peak torque 75A

Continuous stall current 13.2A

max voltage - 140

Tacho 7 ??

The other

Milltronics MT30U4-38 -Spindle

26 inlb stall torque 3Nm

Voltse ggradient no load 38V/kRPM

max RPM 3700

volts 140

Amps 45

Tacho 7 ??

Continuous stall current 8.6A

IP 44 (peak current??)

IC 40 (continuous current??)

Encoders on the

motors: dynamics research corp encoder 152-021-500-18UJ

Look to be 500 per rev

Possible new replacement

https://www.rls.si/eng/products/rotary-magnetic-encoders/re36-rotary-magnetic-shaft-encode

1270 is divisible by 254 as is 508,762,1016,1524 - Such a resolver

should read metric direct - not available..Lubrication System and

Tubing Parker

NNR-3-039

needs connector with sleeve -- brass insert 63PT-3-25

Compression - Inch 3 68C-3-2

Compress-Align 3 68CA-3-2 (nut and sleeve only 61CA-3 ) pipe nut is

0.375 (3/8")

Lubes

Mobil Grease 28 - spindle ball bearings and ballscrew - thrust ball

bearings - think of this as ball bearing grease

Lithium grease - Mobilux

EP 2 Bevel gears, spindle spline - not in manual

The ways, outer spindle shaft calls for Mobil vactra

#2 via lube system - hand apply to ram bearings - this is

the same as any ISO 68 slide-way or way oil.

The sandwich Assembly Gearbox calls for Shell X-100

S.A.E. 10 W this is obviously not at all optimal - for

several reasons. It is an old obsolete engine oil - and this is a

transmission. Engine oils are for extreme environments, controlling

combustion materials etc. Looking back - it appears this was

specified based on what other machines used all of which goes back

to the 1930's where they needed something that would basically work

and was readily available. This machine had 5 yokes worn out

that came with it. They specified SAE 10 - which is about

ISO32 - perhaps because the main shaft can turn at 4200 rpm for

hours at a time?

Looks like Mobil SHC 624 ISOVG32 would be much better..

Capacity is about 0.75l

Way covers

Important note - there are both 10-32 and 10-24 screw threads in

these machines - the way wipers use 10-24.

Tramming the nodd

Possibly with moglice and a copper crush ?

Kwik-Switch - on

the tapers page

Number stamped on spindle - 807-01

Ball-screws

Saddle and table

ball-screw bearings

Saddle and table ball screw bearings are MM9308WI 2H DUH

DUH means "Duplex Universal-heavy preload for precision bearings."

Duplex Angular Contact Bearing - Face to Face, 40 mm Bore, 62 mm OD,

1.2500 in Width, 60 ° Contact Angle, C0, Open

885-007-002 Ball screw bearing set

$618.75 (too much)

The shims = 50mills - varies

The Nilos Rings (dustcover/shields)

886-001-00006 seal $54.20

(058-010-150 ??)

885-001-007 seal

$56.50 (058-010-151 ??)

Collar Threaded B300-010n

Z-axis ball screw

Shims = 30 mills (not proper color code)

Duplex Bearings are FAFNIR MM9306WI-2 mounted face to face.

The other end is a torrington J-1210 that I'm replacing with a

Koyo.

The box that this is mounted in has 2 dowel pins that were

MISSING! Could be there is enough slop that they should be? (poor

quality?)

The ballscrew for Z says NSK Japan W3202W-2LP-upz 9nx-040

Spindle

Change to a # 30 taper spindle??

According to Wells-Index "The spindle taper is not

grind-able as it has to be a specific depth in relation to the nut

that holds the tool in so you have to grind it deep and then build

it back up with hard chrome and then grind it again to the correct

depth. This is doable but the hard chrome starts flaking off after

a while. We have tried this before and the results were not

satisfactory. If the spindle taper is bad the spindle has to be

replaced with a new spindle and the bearings also need to be

replaced. If you do not have any tooling I would suggest replacing

it with a #30 taper spindle [probably means a BT30 taper] as this

is a better spindle with tooling readily available from us and

other companies. The #30 can also be touched up by ID grinding

later in the machines life. "

So I'm not sure the above is totally true? There is always

some tolerance in these systems - there must be some tolerance - the

taper of the cams of the tool-holder nut would consume some amount

of touch up? Will measure it when I have it apart next.

There is a snap ring at the top of the spindle.

where the Z ball screw attaches spindle was stamped "E15"

The kwik-Switch holder says: (starts with an small u or upside

down bell mark) 805043 Kwik-Switch II PAT 3829109 -- part number of

"Master Spindle Nut Assembly"

Looking down the top of the spindle - there is a snap-ring holding a

bearing - on the outer ring says "3007 Germany 1.13"

Inner ring - "6007ZR FAG"

Sandwich Assembly

This was an interesting design - no problem with back gear

reversal - but some things are not so good - and some notes are

critical.

Sandwich Assembly

Important things

not to be missed

First, the 'back gear housing' (ref-98) was made of cast aluminum -

while the belt guard housing(ref-63) was cast iron. This difference

in metal - or perhaps just machining slop ended up with the

recommendation to NOT use the dowel pins. Instead, (with everything

upside down for gearbox assembly) before tightening the 8 bolts that

hold things together - put a mag-base on the shaft and sweep the

bottom of the gear-housing - shifting slightly (pry with screwdriver

in dowel holes) until it is running as true as possible.

(obviously quite fiddly for a machine tool set up ). The

drawing HAS dowel pins - so I would first assemble with pull dowels

and remove only if needed to get the drive shaft to run true.

The total head is aligned to the mill with a floating procedure - it

is not pinned!

Fork assembly - put a mag base and indicator on the pulley shaft and

indicate the brass fork to be parallel to the end of the shaft by

rotating the shaft while the indicator is touching the yoke where

the shift gear rides. Needs to be within .005”

Adjusting the

end-play

Very important to under stand the stack-up or end-play of the

main shaft! There are two end play numbers - first the

main shaft - "The end-play or stack-up clearances are 305um- 356um

[.008" - .012"] when assembled" . Realize that 'speed adjuster

cam' (ref 14) sets the vertical of the pulley shaft (ref 28) - it is

trapped against 'retaining cap'(ref 12) which is against 'Cam

housing' (ref 17) which is mounted to the 'belt guard' (ref

63). A shim between the last 2 references can raise the shaft.

The height of the 'drive gear shaft' (ref 80) - is set by the

combination of the 'bronze washer' (ref 79) and the two turcite

washers and boss gear (ref 82 & 85). Important to have the lower

turcite washer (ref 85) in the grove of the boss gear before

reassembly. The 'drive gear shaft ' is constrained at the bottom

where the turcite washer meets the 'back gear housing' - there

should not be a groove.

Measuring end-play:

Assemble the gears with everything upside down. Put an

indicator on the end of the shaft and lift to measure play.

A Shim in-between Speed Adjuster Retaining Cap ref-12 and cam-housing

(ref-17) increases end-play. A shim in-between Speed

Adjuster Retaining Cap ref-12 and Speed Adjuster Cam

ref-14 reduces end-play.

Remember to true the drive shaft to the bottom of the gear housing

by mounting an indicator on the shaft and sweeping the bottom of

gear housing (98) an indicator..

This leaves the back gear assembly - that has a 1/4 hole that holds

a ball bearing to limit clearance to the fan housing -- > might

be better to come up with a thrust washer?

BACK GEAR - not

really - does not reverse!

(See Drawing #101-212-204)

The back gear lever (shift lever #100-002-900 ref(71)) is located on

the upper left side of the head. The lever has 3 positions; high,

low, and neutral. In the high (out) position, spindle drive is

geared directly from spindle pulley to spindles (dog clutch

#100-002-991 is in up position, in contact with drive cone pulley

hub #100-002-999). In the low (in) position, spindle drive is geared

through back gear #100-002-985 (dog

clutch #100-002-991 is in down position, back gear #100-002-991 is

in mesh with back gear #100-004-557),

NOTE: 2 When shifting from neutral to high or low, turn

spindle by hand while pushing back gear lever into position.

This allows gears to line up in low speed and dog clutch to line up

in high speed. When shifting into high it is imperative to have the

spindle brake in the "brake on" position. [YMMV - I've

not had to put the brake on - just fiddle a bit]

Removal of 3hp

Spindle motor

- Shut off the power and move the speed lever to 4200

RPM .

- Remove the two 3/ 8 hex cap screws which hold the motor

bracket to the pulley guard assembly.

- Slide the motor forward toward the spindle as far as possible.

Then by working the variable speed belt over the edge of the

bottom sheave of the motor pulley, the motor will then be free

of the belt. To help with this - a pulling tool - and put a

wedge above the belt to keep it from jumping back in.

- The spindle motor can then be lifted off the pulley guard.

- It may be necessary to force the motor pulley flanges

apart a little to facilitate slipping the belt over the pulley.

Procedure for

removing sandwich assembly for replacing oil seal in back gear

housing and other repairs.

- Remove the spindle motor first - siphon out the oil

ahead of time - small diameter tube can bend down. Removing

brake lever can prevent it's damage.

- Now remove the 1/ 2-13 hex nuts (3) which holds the

back-gear-housing (bottom half of the sandwich assembly) to the

top of the head.

- Move the spindle and quill down to its lowest level so the

sandwich assembly does not have to be lifted as far. (also

protects the spindle shaft a bit) . Remove the three 1/2-13 nuts

three nuts on the bottom of three vertical bolts. Assembly will

lift straight up - not something just anyone can heft - be

careful. It needs to be lifted level as the spindle's splined

end will bend if the sandwich assembly is not lifted

correctly. The back jack-screw thread is close to center

of gravity. Put nuts on studs to protect threads.

- Now lift the entire assembly off the spindle spline and the

top of the head, and lay onto a suitable work bench with the

three studs at the top and the mounting surface for the spindle

motor on the bottom. (this upside down position is what you want

for the gear-box assembly).

- Remove the retaining ring and remove the slinger plate.

(ref-93 & 94).

- Remove the eight 1/ 4-20 x 7/8 socket heads which hold the

back gear assembly to the pulley-guard-casting (top half of the

sandwich assembly) and lift the back gear housing away

from the pulley guard. (Ref-97)

- This exposes the drive shaft which can be removed by lifting

out of the back-gear-housing thus exposing the top side of the

oil-seal (92) which can then be tapped out of the casting, being

very careful not to damage the (Fafnir 2815 INA - might be?)

bearing.

- Clean everything.

Reassembly of gear

box

- Make sure there are no burs or excessively sharp edges on the

drive shaft - that might damage the seal.

- Replace the eight 1/ 4-20 x 7/8 socket heads which hold the

back gear assembly to the pulley-guard-casting snug - don't

tighten.

- Put a mag-base on the shaft and sweep the bottom of the

gear-housing - shifting slightly (pry with screwdriver in dowel

holes) until it is running as true as possible. The dowel pins

are not normally used.. tighten and recheck.

- Now place the seal on the drive shaft and, being very careful,

start the new oil seal back into the back gear housing with the

lip of the inner race of the seal setting properly against the

OD of the drive shaft. You will want a pipe of the correct

diameter to press this in.

- Reinstall slinger-plate with clip ring.

- Reinstall on the mill - gently - spacers can help get a square

approach.

- Don't forget to put oil in!

- After reassembling:

- Shift the speed range into the direct drive or up position

on the back gear lever. Run the spindle speed at

approximately 1200 RPM with the quill fully retracted into the

head casting.

- Loosen the three 1/2" nuts which hold the back gear

housing (100-009-204) to the top of the head, thus allowing

the back gear and pulley guard assembly to "float".

- Then by snugging up the 1/2" nuts, preferably the front one

first, the back gear assembly will tend to center itself.

(NOTE: A little experimenting may have to be done if

tightening the

front nut first does not eliminate any shake.)

- In rare cases, the pulley guard housing could have been

shaken out of line from the back gear housing. In this

case, the eight 1/4-20 x 7/8 socket heads which hold these two

assemblies together will have to be loosened slightly and the

unit allowed to center itself[ But these are centered with

pull dowel pins?].

-

Removinge

motor variable drive pulley spring assembly

- Remove inner shaft bolt and washer

- screw in 1/2-13" bolt turn until free.

To remove vertical

spindle pulley (drive cone pulley - CAM housing)

Remove 6 socket head screws holding drive pulley cartridge(12) to

pulley guard. (2 tapped holes (3/8"-16) provided in this part for

jack screws)

Lift out drive pulley cartridge (containing drive cone pulley,

spindle bearings and spindle bearing support).

Assembling Cam

housing

- There may be a gasket/spacer between the 'Cam housing' (ref

17) and 'belt guard'(ref 63) not shown. This is a shim and can

have varying sizes depending on what was needed at time of

assembly to get the stack-up of the main shaft correct.

- When reassembling - loosen both sides of the brake!

- Inside of the 'Upper Pulley Face Assembly' (ref 26) are two

yellow parts (nylon?) - not shown on the diagram - Part number

is 898-076-002 "spindle pulley key" each

- Where the bearing (ref 32) fits into the 'belt guard'(ref 63)

can be a bit loose - Use a bit of Blue Locktite 248 which

is a paste or its liquid equal 242.

- Assembly order for the pulley shaft - Install the cam follower

before the 'speed adj bearing housing'(ref 21) onto the

pulley:

- install 'cam follower' (ref 19)

- pulley bearing (ref 24) goes into 'speed adj

bearing housing'(ref 21)

- install 'retaining ring' (ref25)

- install 'retaining ring' (ref 20)

- install above hot onto a cold 'Lower Pulley Face

Assembly' (ref 27)

- There is a trick to disassembly/reassembly of the top sheave

shaft. ref-#19 is in the way of removing a retaining

ring. Get a cheap pair of straight snap-ring pliers and

bend the legs bow-legged.

- Temporarily leave out Wavy Washer (ref 10) - screw speed

adjuster tight - this sets the height of the bearing in the

'belt guard housing' (ref 63 & 32).

- Use 'pull dowels' ref (16) on the 'Cam housing' (ref

17) - next to these is a threaded hole (3/8-16) That can be used

to aid disassembly.

- With the belt guard housing all assembled and upside down -

Using parallels - measure to the top of the pulley gear?

- With the 'back gear parts assembled - using parallels measure

to the top of the bronze washer that is the bearing / spacer

(ref 79). The clearance should be .008-.010". To correct this

you would add or take away shims between the pulley guard and

Cam housing as stated above

- Yoke should be parallel within .005” of the pulley guard

mounting surface or with an indicator sweeping the yoke with an

indicator mounted to the pulley shaft gear.

- With indicator on 'slinger' Position back gear housing to belt

guard housing so the shaft is running square with bottom of back

gear housing.

Brake

TO ADJUST THE

SPINDLE BRAKE:

- Start the spindle.

- Turn 1/4-20 set screw Ref(50) in until you hear the brake

rubbing, then back the set screw out just enough to stop

rubbing. Lock in place with jam nut.

- Turn brake handle in bent position so that (ref(58) shaft

rotates clockwise until you hear the brake rubbing, then turn

counter clockwise just enough to stop rubbing & allow the

handle to be hanging down. If the handle is pointing up when

properly adjusted, knock the 3/16 dia. spirol pin ref(60) out,

reverse the handle 180 & replace the pin, so that the handle

is hanging down.

Spindle

speeds

Back gear lever (high, low, or neutral).

On the variable speed drive head are even more readily changed by

moving the control lever from left to right or right to left

with the spindle motor running

and by shifting the back gear (high low or neutral).

CAUTION: Always be sure spindle motor is running before

attempting to move variable speed adjustment lever.

Motor magnetic

brake

Made by Reuland?

Type OADA

Model 29B2

Not going to use - takes 3ph - not worth it.

Bearings

top to bottom - See sandwich spread sheet for details

13 - FAG 6009ZR (ZR = ONE METAL SHIELD, RADIAL TYPE)

Bearing (6009-2Z/C3 )

24 NSK 6012Z ( koyo )

32 JT51 ?? 60mm id 95 od 18mm 6012 size again - with seals.

???

78 INA (Schaeffler) - SCE228

84 J-2816

105 (2) B-1416

Looks like Torrington J-2016 C DHHH at the bottom..

Size Weight

ceiling height old shop

beams 83.5" 93" add 3" for south end

new shop

91.25" - beams 103" - top

machine with the motor removed? 84 Inches

Shipping weight for a CNC mill is 3700 lbs. 1680kg 16458Nthread5/8

Moving

- Shipping weight for a CNC mill is 3700 lbs.

- Height of the machine with the motor removed = 84 Inches

- Lower table and Center table left to right. Move as close to

column as possible. Center over arm in and out.

- Pick up by over arm with fork lift at front and back of column

or use straps in same locations - use wood to protect the way.

- Do not slide forks under base of mill as mill is top heavy and

will fall over. This is the most common mistake made!

History

Serial number 20567 (1980) Serial number 20567 is a USA made mill

and shipped without a model number in November 1979 to a company

in Texas who installed the control on it for the 1980 IMTS show in

Chicago. Parts are still available for the mechanical part of the

machine.

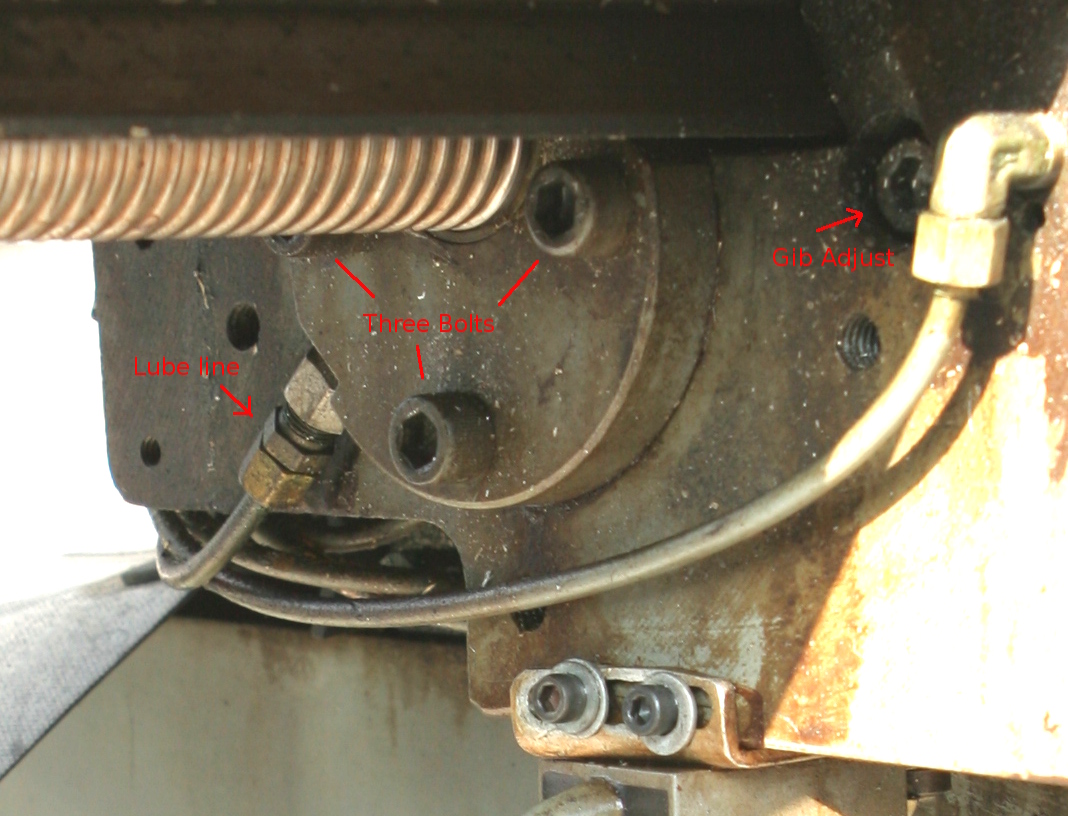

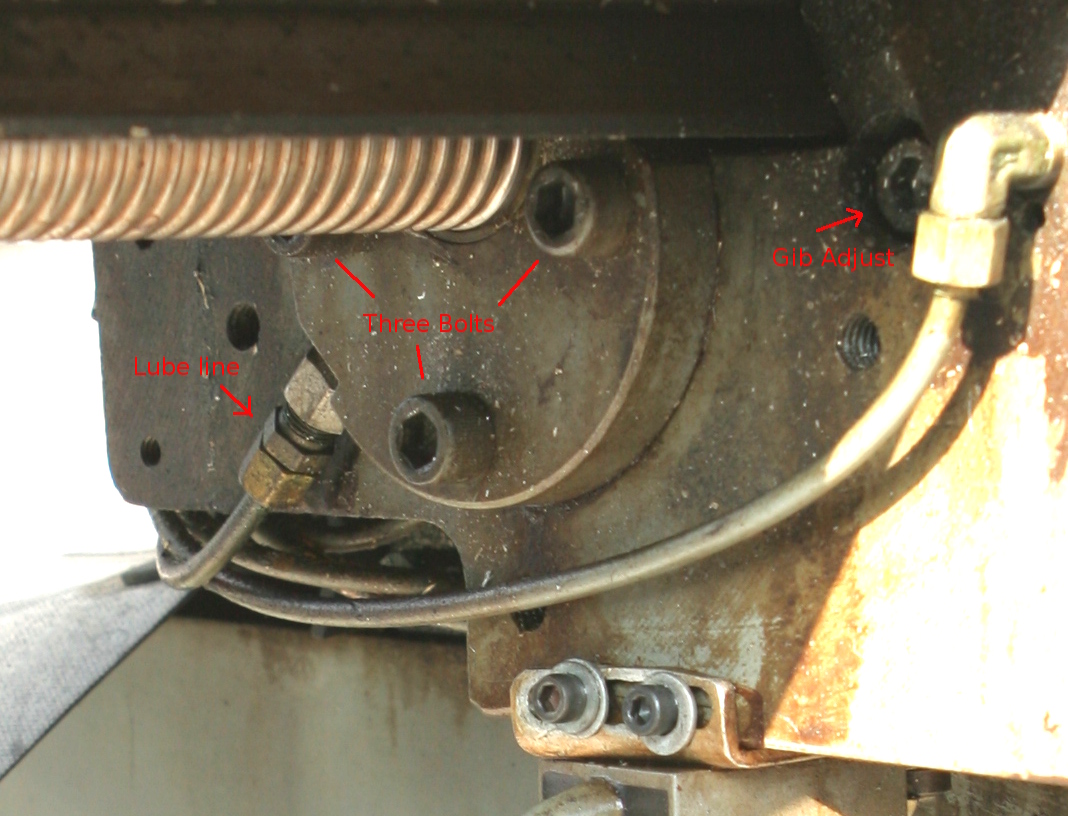

Removing The Table

- Remove the servo assembly from the left end so that the table

can be handled more easily.

- There are three bolts that hold the ball screw traveler to its

base - remove these and remove the lubricating tube.

Ball Screw Traveler and gib

Click to see details

Remove the gib adjustment screws on both end of the gib and then

slide the gib out to the left.

There is also a stop piece on the bottom of the far right end of

the table that needs to be removed with it's one bolt.

Table Stop

Click to see details

- You may have to remove limit switches.

- Remove the adjusting bolts from both ends of the gib - slide

the gib out to the right - mark the end and orientation before

it is completely out.

- Support the table with bolts in T-slots (make sure they can't

move horizontally). An engine sling and hoist works well to

support the table evenly as you slide it out.

You need to remove the ball screw and table bracket on both ends and

then the gib. . The ball screw can stay assembled with the left side

table and motor bracket assembly. You can then slide the table out

onto a cart

Rebuilding table - really good idea to seal the table so coolants

can't get into the bearings..

Ram (AKA Overarm)

The back to front position of the head and overarm is readily

changed by loosening the 2 hex nuts on the end which clamp the

overarm to the turret. Apply a crank to the overarm

adjustment shaft extension and move to desired position.

Turret

To index the entire turret-overarm-head assembly loosen the 4 inner

hex nuts, 2 on either side of the overarm which clamp the turret to

the top of the column. Then swing

the turret to the desired position and re-clamp. The

complete horizontal spindle, turret, overarm & arbor bearing may

be positioned 30deg either side of normal horizontal milling

position.

NOT E : It is highly recommended that all clamping nuts and bolts

(turret to column, overarm to turret, head side-wise tilt and head

forward-back tilt) be securely tightened before any machining cuts

are taken. Always check these points before starting a cut. Also,

when returning overarm to normal position, attach an indicator to

the overarm, and slide the overarm in and out, with the indicator

riding against a square, which has been squared to front of table to

make sure overarm is square with table. (Why would anyone change

this?)

wiring

http://linuxcnc.org/docs/devel/html/integrator/wiring.html

(BNTECHGO) Or what they call continuous flex cables. (keywords

Continuous-flex Cables high strand count)

Notes for similar

machine

INSTRUCTIONS FOR

CHANGING SPINDLES IN THE FOLLOWING MODELS 745. 747. 756, 757, 845,

847, 856, 857,760, 860, and 887.

- Remove drawbar if it has one.

- Drop knee and move saddle to rear so as to provide clearance

for quill removal.

- Remove (100-027-771) adjustable vernier blade holder.

- Remove two 5/16-18 x 7/8 socket head cap screws in

(100-002-917) quill feed trip key and remove key. Put right hand

on (101 -212-312) spindle feed handle arm and left hand on the

bottom of the quill, and by moving the (101-212-312) handle in a

counter clockwise direction, run the quill down until the rack

on the quill clears the pinion on the cross shaft.

- When this happens, the (101-212-312) hand lever will unwind

very rapidly. If released, it could cause injury. So it must be

unwound slowly.

- Let the quill slide down out of the head casting and put it in

a vise, being sure to use brass or lead jaws in the vise.

- Release the locking ear of the W-07 lock washer in the N -07

locknut or snap ring in the top of the quill and remove nut from

the spindle. (See Paragraph 11) See drawing

- Remove (100-002-972) front bearing retainer from quill after

first releasing the 10/32 socket set screw in the lower rear of

the quill. (NOTE: in the case of #30 MMT, the number is

100002-977.)

- Remove quill from the vise and strike spline or upper end of

spindle against a solid piece of wood laying against a solid

surface, such as the floor. The spindle and the two lower

spindle bearings and spacers will then come out of the quill.

- Replace new spindle and assembly in reverse order making very

sure that the N-07 locknut is tight enough so as to put tension

on the 2968 spacer on serial number before approximately 17105

on R8 spindles and

- approximately 17360 on #9 B & S and #30 MMT spindles.

After this serial number make sure the locknut is tight against

the bearing.

- When putting the quill back into the head casting, first start

the quill into the bore of the casting by gentle pressure and

care (do not force).

- Line up the spline of the spindle with the spline of the

(100-004-576) drive hub by turning the spindle after it goes up

against the bottom of the (100-004-576) hub.

- Next, wind the 101-212-312 counter clockwise to the end of its

spring tension and push quill up until the rack of the quill

engages the pinion of the cross shaft and use (101-212-312) hand

lever to raise quill up to

- the top of its travel.

PROCEDURE FOR

FREEING UP BACK GEAR TO DIRECT DRIVE 745, 756, 760, 845, 856, 747,

757, 860, 847, and 857

This particular problem is usually caused by the (111-218-001)

pulley guard being jolted out of line during shipment and can

usually be remedied as follows:

- Shift the back gear lever into the direct drive (or High) and

set the speed at about 1500 RPM.

- Loosen the eight 1/4-20 x 7/8 socket head cap screws which

hold the (111-218-001) belt guard to the (111-218-212) assembly)

- Turn on the spindle motor, move the (111-218-001) belt guard a

very slight distance in several directions. The dowel pin hole

in the front of the pulley guard can be used with 1/4" allen

wrench to move the pulley

- guard back and forth.

- The pulley guard will actually tend to center itself if

reasonable care is exercised when retightening the eight socket

heads that hold the belt guard to the back gear housing.

Precision limit

switches

They have 3-5um at reasonable prices.

https://www.metrol.co.jp/en/products/

ditron DRO - via Stefan

houdaille taper???

model 3842 -- CEN 701 702 703 752 753 805 ???

lubriquip houdaille cleveland oh

model 120-003-521

timer model 163-400-000

motor IIC Inc MN 55344

30U4-36 S#H 19938

servo motor 2 Milltronic manufacturing

MT30M4-38

jog feed rate

emergencystop

Tool-change resume

feed- hold-pause

###

Stop drill

lockline coolant hose.. 1/4"

FROM TREO

milling machine

servo dynamics corp 15 A module

SD1525-10

B