Disclaimer

This information HAS errors and is made available

WITHOUT ANY WARRANTY OF ANY KIND and without even the

implied warranty of MERCHANTABILITY or FITNESS FOR A

PARTICULAR PURPOSE. It is not permissible to be read by

anyone who has ever met a lawyer or attorney. Use is confined to

Engineers with more than 370 course hours of engineering.

If you see an error contact:

+1(785) 841 3089

inform@xtronics.com

Optic equations and

notes

- Disclaimer

- Optic equations and notes

- Diopter or Dioptre

- Focal Length

- Depth of Field

- Contrast Ratio

- Lens power or Magnification

ratio

- Spherometers - lens Radius from

arc depth

- Rayleigh Water Test - for

testing optical flats

- Wavelength of LED or Laser

based on band-gap voltage

- Colors of wave lengths

- Refractive Indexes 632nm

- Coherence time and Length

- Fast Lenses

Diopter or Dioptre

The diopter unit is simply the inverse of the focal length in

meters.

Thus a +2 diopter lens has a focal length of 500mm

You can combine lenses of different diopters arranged in contact

- thus a -2 diopter lens plus a +4 diopter lens would give us the

same 500mm focal length.

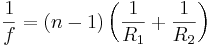

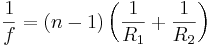

Focal Length

If a lens has surface radii of R1 and R2

and made of glass with an n refractive index the focal length, f,

is defined below

R1 and R2 = surface radii

(negative for convex lens surface)

ng = refractive index of the lens glass

f = focal length of lens

Focal length to angle of view

α = angle of view d = size of film or sensor f = focal

length

Depth of Field

Depth of Field is the minimum to maximum distance in

focus.

Contrast Ratio

Contrast ratio is the difference between the brightest and

darkest point in an image.

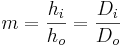

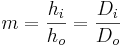

Lens power or

Magnification ratio

Where

m = Magnification ratio or Power

hi = image height

ho = object height

Di = distance from lens to image

Do = distance from lens to object

Spherometers -

lens Radius from arc depth

C of the Triangle is the same as Radius.

The bottom has a calculation of the Spherometers leg from the

radius.

Variables in light optics Greek

V = frequency in hz

ω = radian frequency

δ = path difference (corrected for n)

φ = phase difference

P = order of interference = K

e = thickness

τ = coherence time

l = coherence length

n = index of refraction

a = distance from center

Phase reversal on reflection

Light phase flips (E-field only) when reflecting off a material

with higher refractive index than what it is traveling through.

Brewster angle reflections have no phase change.

If light reflects off an internal wall of a prism or flat - phase

does not reverse.

Phase reversal is important when analyzing coatings.

Rayleigh Water

Test - for testing optical flats

- Monochromatic light source (not LED) - neon/ mercury vapor

sodium

- Leveling platform - fine pitch screws - differential would be

best - but long allen wrench - with long cheater in cap screw

- A lens bigger than the flat - collimator - Fresnel a good bet.

- Black tray - should not rest on bottom of tray?

- Draft preventer - Coraplast taped together

- stable surface - no vibrations - Concrete - add weight to

platform

- LASER pointer

- Magnifier might help see small bands.

- Best water thickness over glass - .9mm± .2mm - A dime is

a bit too thick - but will get you close..

The interference creating bands happens between the water surface

and the top of the glass.

Back to the water test - I'm still not seeing what I want to -

I've started experimenting - trying to see a pattern with a single

microscope slide - the reflection from the front and rear surface

seems close to the water test. (The double slide glass

interference is easy).

To see the single glass, the light and eye want to be very close

together - a normal view point to the surface - It

Getting things level is the hardest bit - point a LASER pointer

straight down - align the dots - and hope you get close. The LASER

should be directly above and aimed so the dots are close to the

LASER - 10mm or less.

The drill is to look without the collimating lens in place - you

want to find rings - adjust so they are wide.. If the rings are

close - a magnifying glass might help. Focus on the image of

the lamp - that is where you will see the first lines. (This

didn't seem to work well - very careful LASER alignment was more

important).

The leveling screws I used were differential - made from a

M8-1.25 capscrew that was drilled out to mount a M6-1.0 -

the thread difference gives 250um per turn.

Fringes formed from a non uniform film (wedge) are called Fizeau

fringes.

Newton rings are a type of Fizeau fringe - the wedge being

concentric from being pressed together at a point.

Haidinger fringes are fringes of equal inclination - pin hole

source best viewed with a large aperture lens. (longer path length

means coherence length is critical).

Wavelength of LED

or Laser based on band-gap voltage

The wave-length in lens specifications is 632.8nm - helium-neon

LASER - (Comes from a persistent neon line --

with low concentrations of a particular element relative to other

substances in the source, the number of observable lines decrease

with decreasing concentration until only the most persistent remain.

Should

have been called a Neon-Helium LASER) but other monochrome light

sources are available - LEDs and LED LASERs

Below is an estimation based on the voltage drop which is close

to the band gap of a forward biased diode.

l = wave length in nm

Eg = band-gap voltage

then

Thus those red LEDs with a 1.9V drop run about 652 nm. (GaAs0.6P0.4)

This appears derived from ,

Where:

- h = Plank's Constant = 4.13 x 10-15 eV·s

- c = speed of light = 2.998 x 108 m/s

Colors of wave

lengths

Infrared 710nm and goes down to roughly 2000nm.

The visible range is considered to be roughly 400nm to 710nm.

390nm to 420 is Blue (or Violet),

530nm is green

Mercury e-line = 546.07 nm

589nm - sodium D lines - a doublet - two lines 589.0 and 589.56nm

- coherence length 0.59mm (must be one line) (588.9950 and

589.5924)

600nm to 710nm is considered red.

632.8nm - helium-neon LASER - neon - bandwidth about

0.002 nm compared to LED bandwidth of 24-27nm -

10,000 wider.

Refractive Indexes

632nm

Fused silica 1.457

Fused Quartz 1.46

Zerodur 1.542

Borofloat 1.472

Clearceram-Z 1.54

ULE 1.48

N-BK7 1.51

Water ~ 1.33

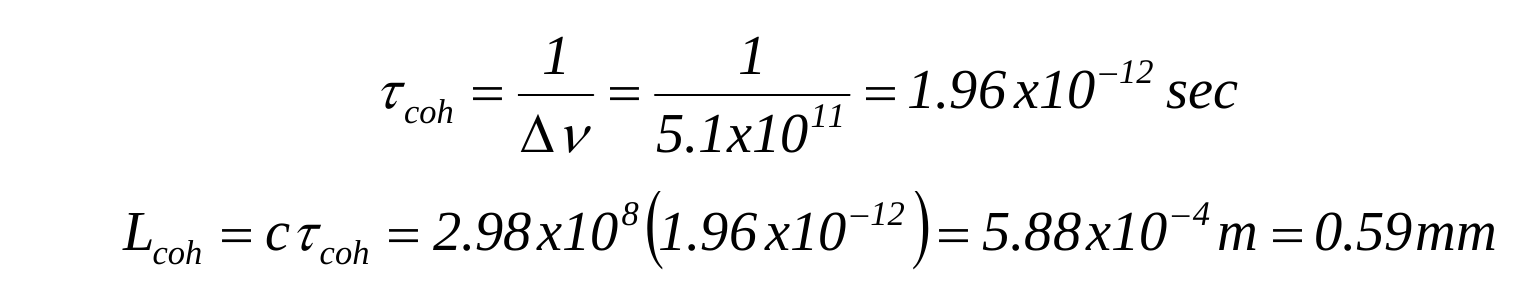

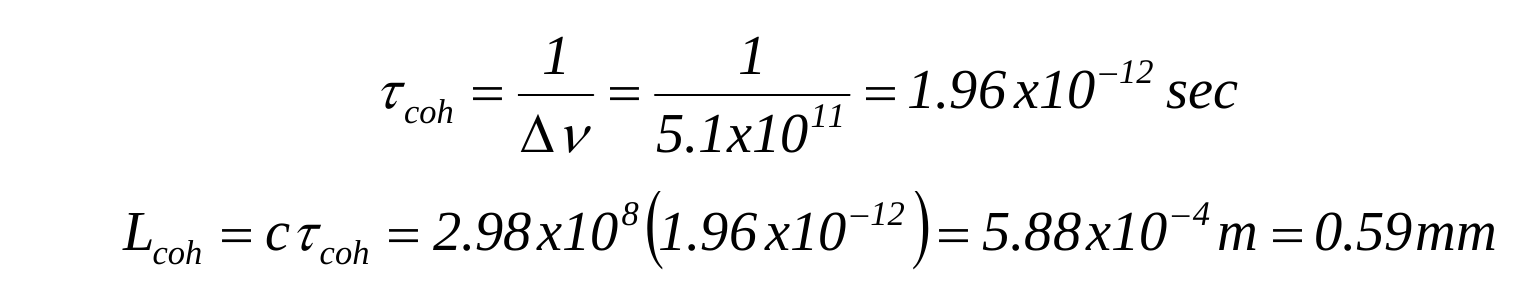

Coherence time

and Length

Example of Coherence Length

Sodium vapor lamp yellow "D" line

• λ = 589 nm and line-width 5.1x1011 Hz

• Thus coherence time and length is

The mercury line at 546.1 is .3mm ?? varies greatly with

tube pressure

Coherence length test

A pen LASER has a coherence length of about 10mm - because the

slide is thinner there is an interference pattern on the

screen. If in place of the slide there was a 15mm optical

parallel - the pattern fails.

Interferometers

Bath Interferometer

The Bath interferometer is not effected by coherence

length. A bit of a puzzle why? The trick is to think

in time - rather than length - thus coherence

time - and to focus on correlation. Light interference requires

the light to be correlated in (average) phase (and to have some

amount of spacial coherence as well).

So for a Newton rings - a type of Fizeau fringe - the time it

takes to travel the two paths - is different - varies in

time. Thus if the source has a short coherence

time - and the difference is greater, the

interference pattern falls apart. When the light arrives - it is

no longer correlated even if at an even cycle time of the given

light frequency.

But for the Bath - the time difference of the path is never

greater than the defects of the mirror under test - those defects

would have to be greater than the coherence length for it to fall

apart. (Imagine a mirror surface with a 10mm defect - the

absurdity makes it memorable <grin>)

The light doesn't care about time varying phase - as long as it is

correlated between the two sources. So if you imagine

that the light source was oscillating in phase like an FM radio

station - limiting the coherence time to part of one of these cycles

- it doesn't matter - the light creating the pattern has the same

phase when it arrives. Coherence time means that phase changes

in time - not because it traveled some length - both beams started

off the same - have the same path length - so will arrive the same

as well. Both arrive highly correlated. So

coherence length matters if the time of flight differs - the key

detail.

The following I think came from Dale Eason - couldn't find the

original link.

Best Practices

The software requires a good “igram” for input – a photograph of the

interference fringes due to interference of the test and reference

beams. These guidelines are meant to supplement Dale’s instructions

with a “Best Practices” for obtaining high quality, clean igrams.

Much of this material is dispersed throughout years of posts in the

messages section.

- XYZ stage - A stable, smoothly controllable xyz stage is

critical to avoid frustration and wasted time in taking igrams.

This can be purchased, for example on ebay, or made (see “A

simple to make Bath and xyz stage” in the Wiki for an example).

Precisely repeatable adjustment as in the wire or caustic test

is not required, just smooth and stable fine adjustment

- Firm foundation - A firm support for the stage and mirror test

stand, such as a concrete slab floor, are also required. A wood

floor generally moves as you shift your weight causing the

fringe pattern to shift. Worst case it may completely disappear

when you move away from the xyz stage after making adjustments.

Also, optical components should be firmly fixed in place, so

they do not move when making stage adjustments.

- Mirror test stand - Using 3 “stops” to define a plane to place

the back of the mirror against in the test stand will facilitate

repeatable positioning of the mirror test session-to-test

session. This works best with two rollers supporting the mirror,

one 45 deg cw (clockwise), the other 45 deg ccw from the bottom

of the mirror, with their axes of rotation parallel to the plane

of the mirror back. No difference in test results was seen

between this type of support and a 'whipple tree' linkage with

rollers at +/- 27 deg from the two 45 degree points for a 22.4"

diameter x 2" thick quartz mirror, i.e. any difference was

within the noise level comparing averages of 30-50 wave-fronts.

A tad of "toe-in" of the rollers helps keep the mirror back

against the 3 support points. The reflected test and reference

beams will then be very close to the same position each time so

that only adjustment of the xyz stage is required to obtain

fringes, with no movement of the tripod or whatever you use to

hold the stage. You can usually find the beams by holding a

screen in front of the flat mirror since they won't be far out

of alignment, and with the above type of test stand support the

only adjustment required will be using the vertical (z) and

horizontal (y) motion of the stage to center the beams, provided

you didn't move the diverging lens or other optical components

from their position during the last measurements. Once aligned

this way, with the reference beam centered on the test beam, you

can then move the camera back, hold the screen there and more

finely adjust so the reference beam covers the test beam. It

typically takes less than two minutes to place the mirror and

adjust the y and z positions (x taken as parallel to the optical

axis) to get good fringes and be ready to take igrams. Some

tweaking of the x position may also be required to adjust the

number of fringes on the mirror. You then of course have to wait

for the mirror to equilibrate in temperature.

- Bath to test mirror distance - A diverging lens position

just inside the test mirror radius of curvature generally works

well. The two beams generally come to focus somewhere inside the

beam splitter. You can fasten a wood block or similar on your

mirror test stand aligned below the mirror center, then run a

tape measure from it to the Bath lens to check distance. Usually

the Bath is mounted on a tripod for rough vertical adjustment.

Move the tripod for initial rough set up of the Bath-to-test

mirror distance.

- Alignment of beams - The test and reference beams should be

approximately parallel to each other. This can be done anywhere

using a piece of cardboard for a screen. The screen can be

placed much further away than the mirror will be during testing

to aid in good alignment. The diverging lens is moved aside when

aligning the beams.

- Beam separation - The distance between the two beam paths

results in some field astigmatism (a property of the surface

being tested). Place the flat mirror so it is almost touching

the bs in a right angle Bath so that you can position the

reference beam on it with less than ~ 8 mm spacing from the test

beam, to minimize Bath-induced astigmatism. The main limitation

on beam spacing will be the cross section of the beams which

determines how close you can place them to the corner of the

cube splitter on a right angle Bath. This also effects how large

a lens you require to be able to relatively easily get both

beams fully captured by it. A 6mm diameter lens was originally

recommended, but it can be difficult to get both beams aligned

in a 6mm lens. Up to 8 mm diameter seems to work fine on most

mirrors, even 9mm. DFTFringe can estimate the Bath and test

stand-induced astigmatism, and testing the mirror at different

rotation angles and averaging the results removes this source of

astigmatism. See Notes about Bath interferometer in the Wiki for

a discussion of Bath astigmatism. Note that not uniform air

density in the optical path can also induce astigmatism, so

always rotate the mirror and test again to see if the

astigmatism is in the mirror or due to air density distribution.

The latter can sometimes be quite a problem, see below.

- Position of diverging lens - After aligning the beams

the diverging lens must be adjusted so the test and reference

beams pass through its center. Misalignment can result in

non-uniform illumination of the test and/or reference beam

resulting in high unwrap errors and wave front distortion. Then

hold a white screen where the camera normally will be, and

observe the test and reference beams and adjust the diverging

lens position until the test beam image of the mirror is round,

and it and the reference beam are both uniformly illuminated.

This is critical for good igrams.

- Laser wavelength - Laser wavelength should be measured for

more accurate results. A number of people have described using a

diffraction grating for this. An example is given in the Wiki

section Measuring laser wavelength.

- Rotating the laser - The laser beam is usually polarized so

rotating the beam (electric field) changes reflection at optical

surfaces and effects the splitting by the beam splitter (BS).

Rotate the laser to determine what angle gives the most uniform

beam and highest contrast in the fringe pattern by observing the

fringes through the camera as you rotate.

- Test and/or reference beam inhomogeneities - The laser diode

beam can have dark areas or “spots”, or “mottling” which can

cause unwrap errors and result in large spikes in the

wave-front. Expanding the laser diode beam by placing the diode

at the focal point of a collimating lens and placing a 2mm to

4mm hole in front of, and centered on the lens can greatly

improve beam homogeneity. The laser diode lens (if any) is

removed in this case. This also generally results in a large,

round reference beam, 2 to 3 times larger than the test beam

when viewed on a screen. This greatly facilitates slight

misalignment of the beams (“tilting”) to adjust the number of

fringes across the mirror image without getting the mirror test

image partly in a darker area of the test beam. This is more

likely to occur with an unexpanded, elliptical or “rectangular”

test beam and may result in such high unwrap errors that the

igrams are useless.

- Many times mottled areas are just due to dust on the optics.

It is important to keep all optical surfaces clean to avoid dark

spots on igrams. Eyeglass lens cleaner and cloths work well. You

can simply slide a plastic bag over the Bath to keep dust off

when not in use.

- Spurious fringes (fringes caused by reflections from the

optical surfaces) - Antireflective (AR) coating of the

diverging lens and the beam splitter (bs) can greatly reduce or

eliminate these. They can be quite distinct with uncoated

optics, resulting in very high unwrap errors – 3k to 7k and

useless wave fronts. They can sometimes be moved off to

the side enough to get usable igrams by rotating the bs a bit,

but this may not be possible. If you rotate the bs, remember you

have to re-align the beams. Rotating the interference fringe

pattern so the fringes are about normal (perpendicular) to the

spurious fringes can significantly reduce unwrap errors, but

they may still be greater than 1k to 2k.

- Fringe print through - The fringe pattern may sometimes be

seen in the wave front as a series of ridges in the shape of the

fringes. Usually reducing igram brightness will reduce these

(say reducing exposure from 1/80 sec to 1/100 sec depending on

your camera/lens and laser diode power). Fringes should be just

bright enough for you to see the edges to place the mirror

outline. Taking igrams at two different fringe orientations on

the mirror will usually eliminate fringe print through.

- Distortion due to air currents and/or stratification - A

tunnel generally reduces air currents, reducing distortion of

wave fronts. A heavy fabric like canvas, or a rigid material

like a cardboard concrete form that resists movement aids in

this. Running a fan to homogenize air in the tunnel can

reduce air stratification, greatly improving wave front

smoothness. Run it for just 20 seconds or so to homogenize the

air, wait a about 10 seconds or so (at around 80 F) for the air

to settle a bit, then start taking igrams. The colder the air

the longer it takes for it to settle.

- Testing in cold air, special considerations A tunnel is

essential to minimize air currents due to thermal mismatch

between nearby surfaces and the cold air. Long times are

required for the mirror to come to thermal equilibrium. A fan

cooling the mirror will greatly reduce this time, but it may

still take several hours depending on the difference in

temperature of your mirror figuring area and the test area. It

has been observed that wave fronts obtained after about 3 hours

may differ a bit from ones taken the following morning, with the

center generally shorter compared to the edge in the wave fronts

obtained after 3 hours. Again, depending on temperature

difference in figuring and testing areas. If testing in

cold air, minimize the time you are close to the tunnel entrance

because air warmed by your body will move into the tunnel

causing air stratification and distortion of wave fronts. When

testing in cold air, difference in floor temperature and air

temperature drives air currents, making it almost impossible to

obtain undistorted wave fronts. Covering the floor area inside

the tunnel with foam or other insulating material will greatly

reduce this effect.

Fast Lenses

Translated from French http://www.dg77.net/photo/tech/fast.htm

to add post it here!

Numerical Aperture

Email